-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

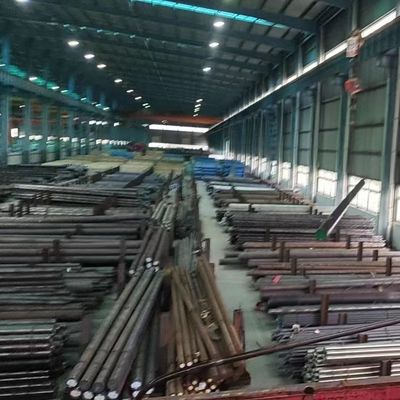

17CrNiMo6 / EN 1.6587 Alloy Steel Round Bar / Gear Steel / Structure Alloy Steel Bar

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 17CrNiMo6 / EN 1.6587 |

| Minimum Order Quantity | 1 Ton |

| Price | 601-886USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products Name | Alloy Steel Round Bar | Diameter | 10 - 350mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

| Highlight | din steel round bar,hot rolled steel round bar,hot rolled mild steel round bar |

||

17CrNiMo6 / EN 1.6587 Alloy Steel Round Bar / Gear Steel / Structure Alloy Steel Bar

Products Specification

| Products Name |

17CrNiMo6 / EN 1.6587 Alloy Steel Round Bar |

| Diameter | 10 - 320mm |

| Length | 6m or custom cutting any length as request |

| Type | Hot Rolled |

| Brand | BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

| MOQ | 1 Ton |

| Loading Port | Shanghai Port |

| Packing | packing by steel wire rope |

| Deliver time | 5 - 7 days for stock materials |

| Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov, 15CrMo,304,316,20Cr,40Cr,20CrMo,35CrMo,42CrMo, 40CrNiMo,GCr15,65Mn,50Mn,50Cr,3Cr2W8V,20CrMnTi,5CrMnMo |

| Standard | ASTM GB EN DIN |

| Application | Structure and Industrial |

Regular Standard Size of our 17CrNiMo6 Round Bar in Stock

| Standard Diameter | 10 12 15 18 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 120 130 140 150 160 180 200 210 220 230 250 270 300 |

Other Alloy Steel Round Bar We Can Supply:

40CrNiMoA,4340,40CrNi2Mo,34CrNiMo6,17CrNiMo6,20CrNiMoA,8620H,35CrMo,Ⅴ40,20CrMnMo,20MnCr5,30CrNiMo8,18CrNiMo7

17CRNIMO6/1.6587 ALLOY STEEL

17CrNiMo6/1.65827 Alloy Steel is is a heat treatable, low alloy steel containing nickel, chromium and molybdenum as per DIN Germany standard which is known for its toughness and capability of developing high strength in the heat treated condition while retaining good fatigue strength. 17CrNiMo6/1.6587 Alloy Steel is widely used in heavy duty Shafts, Gears, Axles, Spindles, Couplings, Pins etc.

| Chemical Composition | |||||||||

| National Standard |

Grade | C% | Si% | Mn% | Cr% | Mo% | Ni% | P% | S% |

| DIN | 17CrNiMo6 (1.6587) |

0.15-0.2 | ≤0.4 | 0.4-0.6 | 1.5-1.8 | 0.25-0.35 | 1.4-1.7 | ≤0.025 | ≤0.035 |

| Size&Tolerance&Process | ||||

| Shape | Size(mm) | Process | Tolerance | Length(mm) |

| Round | Φ6-Φ50 | Cold Drawn | H11 | 3000-5800 |

| Round | Φ40-Φ300 | Hot Rolled | -0/+3mm | 3000-10000 |

| Round | Φ120-Φ1000 | Hot Forged | -0/+3mm | 3000-10000 |

| Flat/Square/Block | Thickness:120-800 Width:120-1500 |

Hot Forged | -0/+3mm | 500-6000 |

Heat Treatment

Normalizing For 17CrNiMo6/1.6587

- 1.Nominal normalizing temperature:840-890°C

- 2.Hold the temperature for several hours

- 3.Cooling in the air

Annealing For 17CrNiMo6/1.6587

- 1.Nominal Annealing temperature:630-650°C

- 2.Cool slowly in the furance

- 3.Maximum Brinell hardness of 229

Hardening and Tempering(QT) For 17CrNiMo6/1.6587

- 1.Nominal Hardening temperature:830-865°C

- 2.Hold at this temperature then quench in oil

- 3.Tempering as soon as possible when the temperature low to ambient temperature

- 4.Heat the steel carefully to a suitable temperature selected by reference to a tempering chart or table

- 5.The usual tempering temperature is 600°C which depending on the actual requirements

- 6..keep the material out of the furnace ,then cool in the air

Mechanical Property( for reference only)

- 1.Tensile strength: 980-1270MPa

- 2.Yield point: 780MPa

- 3.Percentage reduction of area after fracture: 40%

- 4.Elongation after fracture: 11%

- 5.Impact test (+20°C): Longitud – 45~50J

Delivery Condition

- 1.Shape:Round/Square / Flat/Shafts/Rollers/Blocks

- 2.Surface condition:Black surface/Bright surface

- 3.Heat Treatment:Normalized/Annealed/QT

- 4.Straightness:Max 3mm/m(Enhanced straightness may be available on request)

- 5.Length:3000-5800mm suitable for 20″container. above 6000mm,suitable for 40″ container

- 6.Grain Size: 5-8 acc to ASTM E112-96

- 7.Typcial Hardness:HRC28-32

- 8.Ultrasonic Standard: Sep1921/ASTM A388/EN 10228-3

- 9.Non Metallic Inclusion: 2 max acc to ASTM E45 /K4≤20 acc to DIN 50602

- 10.Forging Ratio: minimum 4 : 1

- 11.Marking: Grade/Weight/Length/Size/Heat Number

Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

- 1.Chemical analysis

- 2.Mechanical properties

- 3.Surface hardness

- 4.Non Metallic Inclusion

- 5.Heat Treatment Process

- 6.Grain size

- 7.Forging ratio

- 8.NDE test method/criteria

17CrNiMo6/1.6587 Alloy Steel manufacturers and suppliers, supplied with round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

![]()

![]()

![]()

![]()