-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

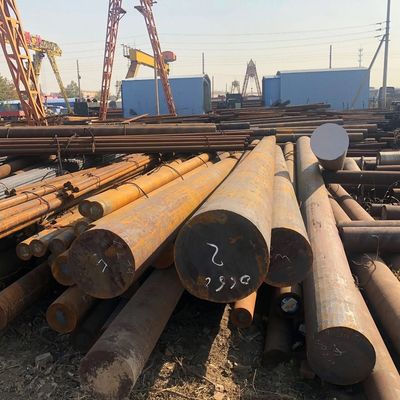

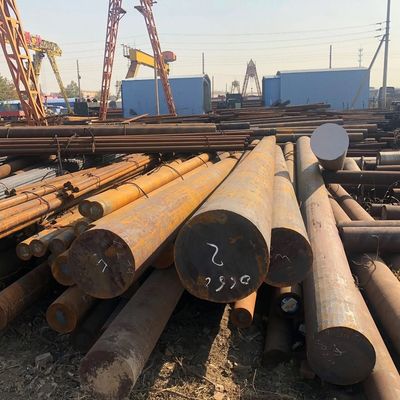

Alloy Special Steel Grade 20CrNiMo13-4 / EN 1.6660 Steel Round Bar

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 20CrNiMo13-4 / 1.6660 |

| Minimum Order Quantity | 1 Ton |

| Price | 600-889USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products Name | Alloy Steel Round Bar | Diameter | 10 - 350mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

| Highlight | din steel round bar,hot rolled steel round bar,hot rolled mild steel round bar |

||

Alloy Special Steel Grade 20CrNiMo13-4 / EN 1.6660 Steel Round Bar

Products Specification

| Products Name |

20CrNiMo13-4 / 1.6660 Alloy Steel Round Bar |

| Diameter | 10 - 320mm |

| Length | 6m or custom cutting any length as request |

| Type | Hot Rolled |

| Brand | BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

| MOQ | 1 Ton |

| Loading Port | Shanghai Port |

| Packing | packing by steel wire rope |

| Deliver time | 5 - 7 days for stock materials |

| Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov, 15CrMo,304,316,20Cr,40Cr,20CrMo,35CrMo,42CrMo, 40CrNiMo,GCr15,65Mn,50Mn,50Cr,3Cr2W8V,20CrMnTi,5CrMnMo |

| Standard | ASTM GB EN DIN |

| Application | Structure and Industrial |

Regular Standard Size of our 20CrNiMo13-4 Round Bar in Stock

| Standard Diameter | 10 12 15 18 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 120 130 140 150 160 180 200 210 220 230 250 270 300 |

1. 1.6660 Application

• Gears subjected to high stresses, diverse parts subject to wear and fatigue in service.

• In the quenched and tempered condition: ety-critical parts.

2. 1.6660 Characteristics

• High mechanical properties.

• Good fatigue strength.

• After carburising, quenching and tempering, the surface hardness is around 730 HV.

• Good toughness of the carburised layer.

• For some carburising applications, oil quenching can be replaced with gas pressure quenching in order to minimise distortion due to the heat treatment.

3.All Grades Comparison

| DIN | EN |

|---|---|

| 1.6660 | 20NiCrMo13-4 |

4.Quality Standard

EN 10084 2008 Case hardening steels

5. 1.6660 Chemical Composition(%)

| C | Mn | Si | P | S | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.17-0.22 | 0.30-0.60 | 0.40 max | 0.025 max | 0.035 max | 0.80-1.20 | 3.00-3.50 | 0.30-0.50 |

6.Hardness requirements for products delivered in the conditions

| Process | Hardness |

|---|---|

| treated to improve shearability | 277HB max |

| soft annealed | 255HB max |

| treated to hardness range | 207HB-255HB |

| treated to ferrite-pearlite structure and hardness range | 197HB-241HB |

7.Conditions for heat treating test bars and treatment of the steels:

| Process | Temperatures (oC) |

|---|---|

| End quench test | 850 |

| Carburizing | 880-980 |

| Core-hardening | 825-880 |

| Case-hardening | 800-850 |

| Tempering | 150-250 |

8.Mill′s test certificate:

EN 10204/3.1 with all relevant data reg. chem. composition, mech. properties and results of testing.

Our Service

![]()

Products Show

![]()

![]()

![]()

![]()