-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

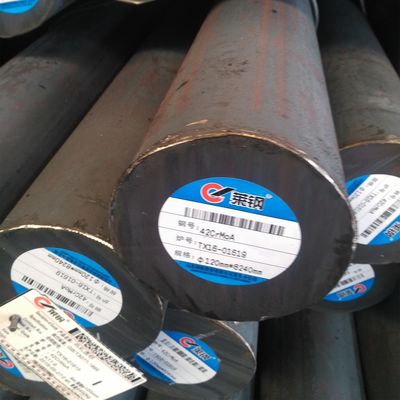

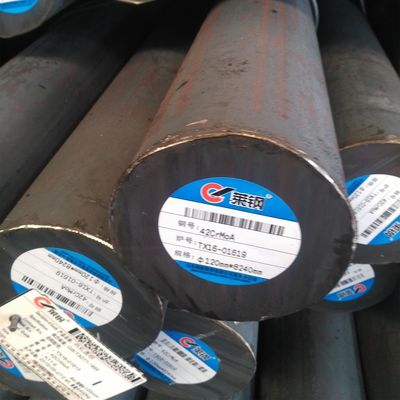

EN 1.6587 (18CrNiMo7-6) Case-Hardening Bearing Steel Round Bar Hot Rolled 10.0 - 320mm

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | EN 1.6587 (18CrNiMo7-6) |

| Minimum Order Quantity | 1 Ton |

| Price | 600-875 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products Name | Alloy Steel Round Bar | Diameter | 10 - 350mm |

|---|---|---|---|

| Length | 6m | Tech | Hot Rolled |

| Service | Cutting | MOQ | 1 Ton |

| Loading Port | Shanghai Port | Standard | ASTM EN GB |

| Highlight | din steel round bar,hot rolled steel round bar,hot rolled mild steel round bar |

||

EN 1.6587 (18CrNiMo7-6) Case-Hardening Bearing Steel Round Bar Hot Rolled 10.0 - 320mm

Products Specification

| Products Name |

EN 1.6587 / 18CrNiMo7-6 Alloy Steel Round Bar |

| Diameter | 10 - 300mm |

| Length | 6m or custom cutting any length as request |

| Type | Hot Rolled |

| Brand | BAOSTEEL DELTA DONGBEI HUAXI SHAGANG.etc |

| MOQ | 1 Ton |

| Loading Port | Shanghai Port |

| Packing | packing by steel wire rope |

| Deliver time | 5 - 7 days for stock materials |

| Other Grade |

Q195,Q235,10#,20#,35#,45#,Q215,Q345,12Cr1Mov, 15CrMo,304,316,20Cr,40Cr,20CrMo,35CrMo,42CrMo, 40CrNiMo,GCr15,65Mn,50Mn,50Cr,3Cr2W8V,20CrMnTi,5CrMnMo |

| Standard | ASTM GB EN DIN |

| Application | Structure and Industrial |

Regular Standard Size of our EN 1.6587 / 18CrNiMo7-6 Round Bar in Stock

| Standard Diameter | 10 12 15 18 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 120 130 140 150 160 180 200 210 220 230 250 270 300 |

EN 1.6587 (18CrNiMo7-6) Case-Hardening Bearing Steel

EN 1.6587 steel is an alloy steel formulated for primary forming into wrought products. 1.6587 is the EN numeric designation for this material. 18CrNiMo7-6 is the EN chemical designation.

It has a moderately high density among EN wrought alloy steels. In addition, it has a fairly high base cost and a moderately high electrical conductivity.

The properties of EN 1.6587 steel include six common variations. This page shows summary ranges across all of them. For more specific values, follow the links immediately below. The graph bars on the material properties cards further below compare EN 1.6587 steel to: EN wrought alloy steels (top), all iron alloys (middle), and the entire database (bottom). A full bar means this is the highest value in the relevant set. A half-full bar means it's 50% of the highest, and so on.

Supply Range of Steel Material 1.6587

Round Bar: diameter 10mm – 320mm

Surface Finish: Black Surface, Milled Surface or Polished Surface as per given requirements.

1.6587 (18CrNiMo7-6) Equivalent Steel Grades

As the casing hardening steel, 1.6587 grade is equivalent to:

- DIN 17210 17CrNiMo6

- AFNOR 18NCD6

- UNE 14NiCrMo13

Chemical Composition: What Makes Up 1.6587 Alloy Steel?

1.6587 material has the chemical composition below per EN 10084 standard:

- Carbon (C): 0.15 – 0.21%

- Manganese (Mn): 0.50 – 0.90%

- Silicon (Si): 0.40%

- Chromium (Cr): 1.50 – 1.80%

- Nickel (Ni): 1.40 – 1.70%

- Molybdenum (Mo): 0.25 – 0.35%

Why DIN 6587 Steel Stands Out

- Versatility: It’s applicable in numerous industries, from automotive to aerospace.

- Durability: Resistant to wear and tear, it’s designed for the long haul.

- Machinability: Despite its strength, it’s relatively easy to work with.

Applications: Where Can You Use 1.6587 Steels?

Due to its properties, DIN 1.6587 grade steel is used for strong and hard parts. It’s good for big parts that wear out quickly and carry heavy loads. This includes parts like big bushings, bearings, cam parts, clutch pieces, bolts for compressors, fan rods, heavy gears, pump rods, sprockets, tappets, wear pins, and wire guides.

Comparing 1.6587 Alloy Steel With Other Alloys

When pitted against other materials, 1.6587 steels often emerge as a top contender. It offers a balance between hardness and toughness, something that not every alloy can promise.

Heat Treatment of 6587 Steel

- Soft Annealing: Heat 6587 steel to 650-700oC, cool slowly in furnace. After annealing, it achieves max hardness of 229.

- Normalizing: 850-880oC, air.

- Hardening: Carburising: 880-980oC. Core Hardening: 830-870oC, water. Case Hardening: 780-820oC, water.

- Tempering:Temperature: 150-200oC

FAQs:

- Is grade 1.6587 suitable for high-temperature applications? While 1.6587 steel is durable, it’s essential to ensure its properties align with specific high-temperature needs.

- How does 1.6587 alloy steel compare to stainless steel? 1.6587 is a case-hardening alloy, whereas stainless steel is known for its corrosion resistance. Their applications differ based on these properties. When you are not sure how to choose the right steel grades, you can contact us anytime.

- Where can I purchase 1.6587 material ? Contact Dongguan Otai Special Steel for all your steel needs.

- Can steel material 1.6587 be used outdoors? Given its properties, it’s suitable for various environments, including outdoors, but always consider protective measures against prolonged exposure to adverse conditions.

- What industries typically utilize 1.6587 material? Industries ranging from automotive to aerospace frequently use this alloy, especially in components requiring strength and durability.

![]()

![]()

![]()

![]()