-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

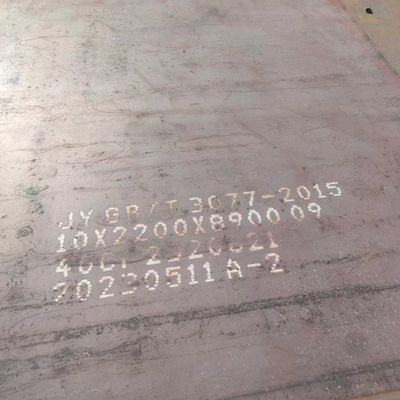

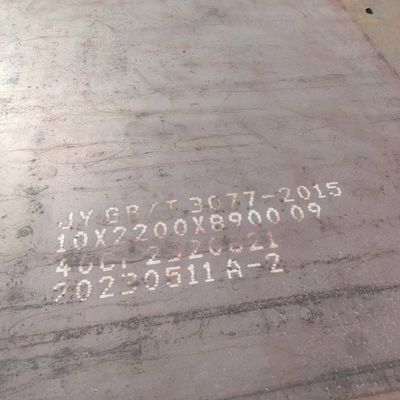

AISI 5140 Alloy Steel Plate Thickness 3.0 - 260mm SAE5140 Steel EN 1.7035 Structure Alloy

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL BENSTEEL HBIS XINGCHENG |

| Certification | ISO |

| Model Number | AISI5140 |

| Minimum Order Quantity | 500 kgs |

| Price | 600-800 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Steel Plate | Thickness | 3.0-260.0mm |

|---|---|---|---|

| Width | 1000-2200mm | Length | 2000-12000mm |

| Standard | ASTM EN GB | Other Grade | SA515GR70,AISI5140 AISI4140 Q355B S235B.etc |

| Brand | BAOSTEEL XINYU XINGCHENG HBIS | Service | Cutting |

| Highlight | alloy steel plate,alloy steel sheet |

||

AISI 5140 Alloy Steel Plate Thickness 3.0 - 260mm SAE5140 Steel EN 1.7035 Structure Alloy

Products Specification of AISI5140 Alloy Steel

| Products Name | AISI5140 Alloy Steel |

| Thickness | 3.0 - 260mm |

| Width | 100 - 2200mm custom cutting any size as request |

| Length | 6m 8m 10m 11.5m 12m or cutting any length as request |

| Standard | ASTM JIS GB EN |

| MOQ | 500 Kgs |

| Deliver time | 7 - 14 days |

| Loading Port | Shanghai Port |

| Packing | wooden pallets |

| Equal Grade | 1.7035 / 40Cr / SCr440 / 41Cr4 |

| Other Grade | 4130 / 4140 / 5140 / 4340 / S355J2/JR S235 1045 1020 65Mn.etc |

| Service | Cutting, Heat treatment |

AISI 5140 steel 1.7035 structural alloy steel

Description

5140 steel has good comprehensive mechanical properties and is one of the most widely used steel types, used for manufacturing parts of medium speed and medium load, such as machine tool gear, shaft, worm, spline shaft and so on. The tensile strength, yield strength and hardenability of 5140 alloy steel are higher than 1045 steel, with higher fatigue strength and good toughness, normalizing or tempering machinability are very good, annealing machinability is also good, generally used after tempering treatment.

Chemical composition

| Grade | C(%) | S(%) | Si(%) | Cr(%) | Mn(%) | Mo(%) | P(%) | Ni(%) |

| AISI5140 | 0.38 | ≤0.040 | 0.15-0.35 | 0.70-0.90 | 0.70-0.90 | 0.06max | ≤0.025 | 0.25max |

Equivalent Of 1.7035 alloy Structure Steel

| USA | Germany | China | Japan | France | England | Italy | Poland | ISO | Austria | Sweden | Spain |

| ASTM/AISI/UNS/SAE | DIN,WNr | GB | JIS | AFNOR | BS | UNI | PN | ISO | ONORM | SS | UNE |

| 5140 / G51400 | 41Cr4 / 1.7035 | 40Cr | SCr440 | 42C4 | 530A40 / 530M40 | 41Cr4 | 2245 |

Heat Resistance

SAE/AISI 5140 steel has excellent heat resistance when it is exposed to temperatures up to 1100°F (593°C). At higher temperatures, the material’s strength decreases somewhat but still remains strong enough for use in many applications. When exposed to temperatures above 1100°F (593°C), the material may become soft and lose its shape but will not melt until it reaches 2700°F (1482°C).

Heat Treatment

SAE/AISI 5140 steel can be hardened by heating it up to 1000-1100°F (538-593°C) followed by quenching in oil or air cooling. This process increases the hardness and tensile strength of the material while maintaining its toughness. The material can also be tempered at lower temperatures after quenching for further strengthening.

Machining

SAE/AISI 5140 steel can be machined using conventional methods such as turning, drilling, milling, sawing, grinding, etc. The material responds well with high-speed tools such as carbide-tipped cutting tools, which are capable of achieving a better finish than other tool materials such as HSS or cobalt steels.

Applications

Gear, shafts, Alloyed case hardening steel for parts with a required core tensile strength of 1000 – 1300 N/mm² and good wearing resistance as boxes, piston bolts, spindles, camshafts, gears, shafts and other mechanical controlling parts.Especially in wheels and stopcock.

Applications included worm, spline shaft, main shaft, oil pump rotor, sliding block, lantern ring, etc.

![]()

![]()

![]()

![]()