-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

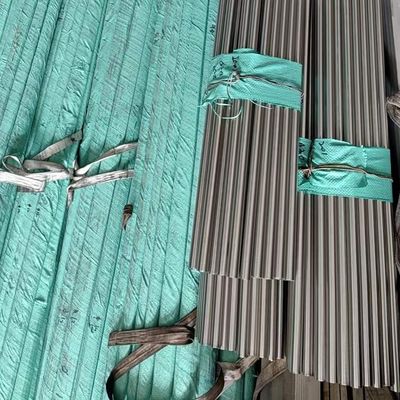

Nitronic 60 Alloy Stainless Steel Round Bar / Bright Polishing SS Bar H7 H9 H11 Tolerance Diameter 4 - 60mm

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 201 304 316L 321 309S 310S 2205 17-4PH 2507 |

| Minimum Order Quantity | 500 kgs |

| Price | 2400 - 3500 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Shape | Angle Bar / Channel Bar | Standard | ASTM EN GB JIS |

|---|---|---|---|

| Grade | 201 304 316L 316LMod 309S 310S 321 2205 2507.etc | Application | Construction,Industry,surgical Tools,seawater Equipment.,kitchenware |

| Length | Customers' Requirements,5.8m,6m,2m-6m,or As Required | Size | Custom As Request |

| Packing | Standard Seaworthy Package,In Wooden Cases(for FCL/ LCL Shipment) | Service | Cutting, Surface Finishing |

| Highlight | stainless steel round bar,stainless steel bar stock,steel round bar |

||

Nitronic 60 Alloy Stainless Steel Round Bar / Bright Polishing SS Bar H7 H9 H11 Tolerance Diameter 4 - 60mm

Nitronic 60 is truly an all purpose metal. This fully austenitic alloy was originally designed as a temperature alloy, and subsequently has good high temperature properties for temperatures around 1800ºF. The oxidation resistance of Nitronic 60 is similar to Type 309 S.S., and far superior to Type 304S.S. This grade is best known for its wear and galling resistance.

The additions of Silicon and Manganese have given this alloy a matrix to inhibit wear, galling, and fretting even in the annealed condition. Higher strengths are attainable through cold working the material and is still fully austenitic after severe cold-working. This working does not enhance the anti-galling properties as is normal for carbon steels and some stainless steels. The benefit to the cold or hot work put into the material is added strength and hardness, and the wear resistance does not decrease noticeably. Chromium and Nickel additions give it comparable corrosion to 304 and 316 stainless steels, while having approximately twice the yield strength. The high mechanical strength in annealed parts permits use of reduced cross sections for weight, and cost reductions through the use of thinner stock.

Chemistry of Nitronic 60 Alloy

Chemical Requirements |

|||||||

|---|---|---|---|---|---|---|---|

| Ni | Cr | Mn | Si | N | Mo | C | |

|

Max |

9.00 |

18.00 |

9.00 |

4.5 |

0.18 |

0.75 |

0.10 |

|

Min |

8.00 |

16.00 |

7.00 |

3.5 |

0.08 |

|

|

Characteristics

Corrosion Properties

The corrosion resistance of Armco NITRONIC 60 Stainless Steel falls between that of types 304 and 316. However, experience shows that in a wear system, a galling or siezure failure occurs first, followed by dimensional loss due to wear, and finally corrosion. Galling and wear must be the first concerns of the design engineer. Although the general corrosion resistance of NITRONIC 60 is not quite as good as Type 316, it does offer better chloride pitting resistance, stress corrosion cracking resistance and crevice corrosion resistance than Type 316 in laboratory conditions. Corrosion tests are not normally performed with NITRONIC 60 High Strength.

Corrosion Resistance

Nitronic 60’s uniform corrosion resistance is better than 304 stainless in most environments. The yield strength of Nitronic 60 is nearly twice that of 304 and 316 stainless steels. Chloride pitting resistance is superior to that of type 316 stainless; Nitronic 60 provides excellent high temperature oxidation resistance and low temperature impact.

Applications using Nitronic 60 are valve stems, seats, and trim, fastening systems, screening, pins, bushings and roller bearings, pump shafts and rings. Other uses include wear plates, rails guides, and bridge pins.

Wear Resistance

This alloy provides a significant lower cost way to fight wear and galling compared to Nickel or Cobalt based alloys.

| Wear Compatibility of NITRONIC 60 wear compared to Cobalt 6B and 17-4PH Against Various Alloys |

||||

| Alloy | Hardness | 17-4 PH (HRC 43) |

NIT 60 (HRB 95) |

Cobalt 6B (HRC 48) |

| 304 | HRB 99 | 24.7 | 6 | 3.1 |

| 316 | HRB 91 | 18.5 | 4.3 | 5.5 |

| 17-4 PH | HRC 31.5 | 66.1 | 4.9 | 2.7 |

| 17-4 PH | HRC 43 | 52.8 | 5.4 | 3.8 |

| NIT 32 | HRB 95 | 17.2 | 3.2 | 2 |

| NIT 50 | HRB 99 | 15.7 | 3.5 | 2.9 |

| NIT 60 | HRB 95 | 5.4 | 2.8 | 1.9 |

| Cobalt 6B | HRC 48 | 3.8 | 1.9 | 1 |

| Chrome Plate | --- | 3.3 | 2.1 | 0.3 |

| Silicon Bronze | HRB 93 | 2 | 2.2 | 1.9 |

| K-500 Monel | HRC 34 | 34.1 | 22.9 | 18.8 |

| 416 | HRC 24 | --- | 5.5 | 43 |

| 431 | HRC 32 | --- | 3 | 1 |

| Waspaloy | HRC 36 | --- | 3.1 | 2.4 |

| IN 718 | HRC 38 | --- | 3.1 | 2.7 |

| IN X-750 | HRC 36 | --- | 5.5 | 8 |

![]()

![]()

![]()

![]()

TYPICAL APPLICATIONS

Commercial applications for this engineering material include:

- Bridge pins and hangers

- Valve stems, seats and trim

- Compressor shafts

- Boat shafting and mooring pins

- Bolts/nuts

- Pump wear rings

- Chain-drive systems – pins, bushings, wear rails & roller bearings

- Automotive valves