-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

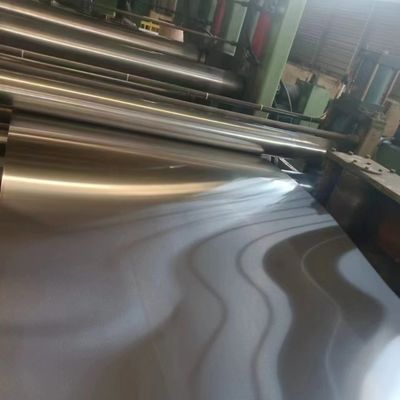

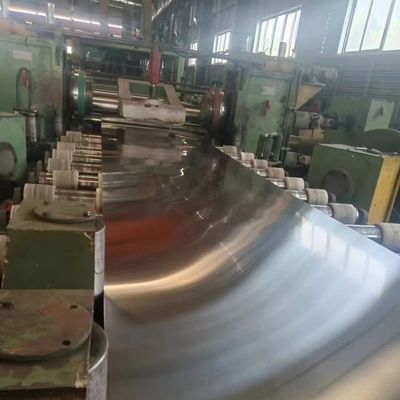

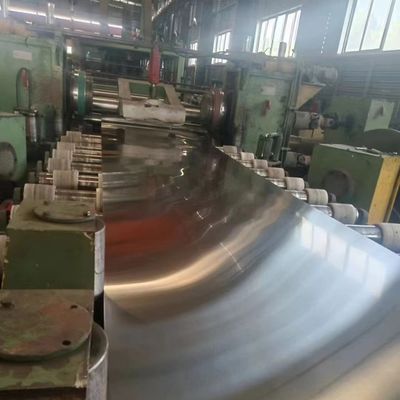

Inconel 625 Alloy Sheet / Alloy 625 Plate UNS N06625 Thickness 1.0 - 12.0mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Nickel Alloy Plate | Grade | Inconel 625 |

|---|---|---|---|

| Thickness | 0.6 - 30.0mm | Width | 1000mm 1219mm 1500mm |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B NO.1 |

| Highlight | UNS N06625 Alloy Sheet,12.0mm Alloy 625 Plate,Alloy 625 Plate |

||

Inconel 625 Alloy Sheet / Alloy 625 Plate UNS N06625 Thickness 1.0 - 12.0mm

Products Specification

| Product Name | Nickel Alloy Plate & Sheet |

| Thinckness |

Cold rolled:0.3mm-3mm Hot rolled: 3.0mm-30mm |

| Standard Size | Cold Rolled 1000*2000mm 1219*2438mm 1500*3000mm |

| Hot Rolled 1500*6000mm 1800*6000mm 2000*6000mm | |

| Service | Cutting (laser cutting, plasma cutting, cutting machine), Bending, forged produce |

| Surface Service | Raw finishing (2B NO.1) Finishing(HL 8K Checkered.etc) |

| Standard | ASTM, AISI, DIN, EN, GB, JIS |

| Mainly Grade | ASTM Grade: Incoloy 800 / 800H ,Incoloy 825,Inconel 600 , Inconel 625 ,Inconel 718, Inconel X-750,Inconel690,Hastelloy B , Hastelloy B-2 , Hastelloy C276 , Hastelloy C4, Hastelloy C2000, ASME Grade: N08800 N08810 N08825 N06600 N06601 N06690 N10001 N10665 N10276 N06455 N06625 EN 1.4588 2.4858 2.4817 2.4642 2.4617 2.4819 2.461 2.4856 |

| Brand | TISCO BAOSTEEL ZPSS LISCO JISCO |

Alloy 625 is an austenitic nickel-chromium-molybdenum-niobium alloy possessing a rare combination of outstanding corrosion resistance coupled with high strength from cryogenic temperatures to 1800°F (982°C).

The strength of Alloy 625 is derived from the solid-solution hardening of the nickel-chromium matrix by the presence of molybdenum and niobium. Therefore, precipitation-hardening treatments are not required.

The chemical composition of Alloy 625 is also responsible for its outstanding corrosion resistance in a variety of severe operating environments along with resistance to oxidation and carburization in high temperature service. The alloy is resistant to pitting, crevice corrosion, impingement corrosion, intergranular attack and is almost immune to chloride stress corrosion cracking.

Alloy 625 can be easily welded and processed by standard shop fabrication practices.

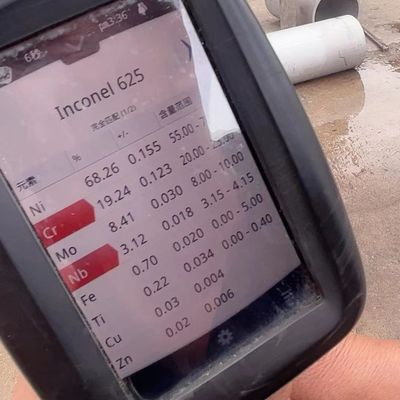

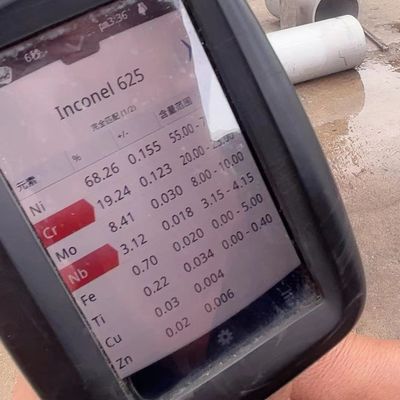

Chemical Analysis

Weight % (all values are maximum unless a range is otherwise indicated)

| Nickel | 58.0 min. | Silicon | 0.50 |

| Chromium | 20.0 min.-23.0 max. | Phosphorus | 0.015 |

| Molybdenum | 8.0 min.-10.0 max. | Sulfur | 0.015 |

| Iron | 5.0 | Aluminum | 0.40 |

| Niobium (plus Tantalum) | 3.15 min.-4.15 max. | Titanium | 0.40 |

| Carbon | 0.10 | Cobalt (if determined) | 1.0 |

| Manganese | 0.50 |

Inconel 625 Sheet & Plate for All Applications

Magellan Metals offers Inconel 625® sheet in a range of standard thicknesses from 0.010” to 0.156”. Our Inconel 625® plate is available in thicknesses up to 4”. All our Inconel 625® sheet and plate meets a variety of national and international specifications, including:

- ASTM B443

- AMS 5599

- AMS 5869

- ISO 6208

- and others (see table below)

We also offer Inconel 625® wire, bar, tube, pipe, fittings, flanges, forgings, and welding rod.

Applications

- Aerospace Components – bellows and expansion joints, ducting systems, engine thrust-reversers, turbine shroud rings

- Air Pollution Control – chimney liners, dampers, flue gas desulfurization (FGD) components

- Chemical Processing – equipment handling both oxidizing and reducing acids, super-phosphoric acid production

- Marine Service – steam line bellows, Navy ship exhaust systems, submarine auxiliary propulsion systems

- Nuclear Industry – reactor core and control rod components, waste reprocessing equipment

- Offshore Oil and Gas Production – waste flare gas stacks, piping systems, riser sheathing, sour gas piping and tubing

- Petroleum Refining – waste flare gas stacks

- Waste Treatment – waste incineration components

![]()

![]()

![]()

![]()