-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

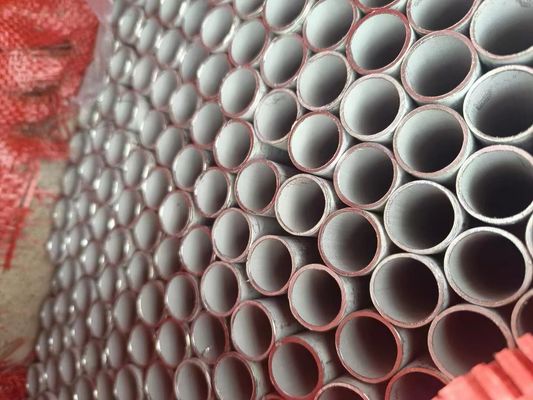

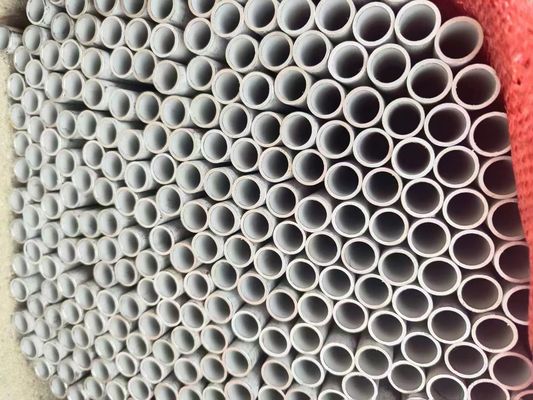

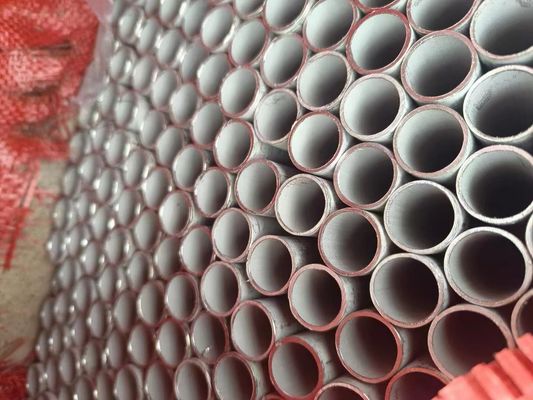

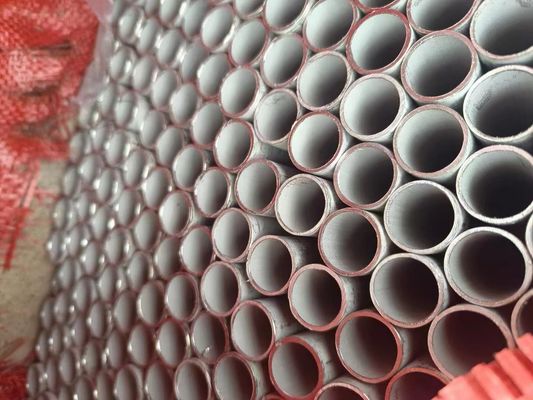

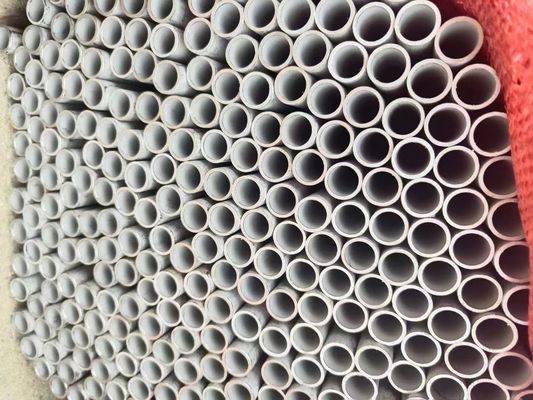

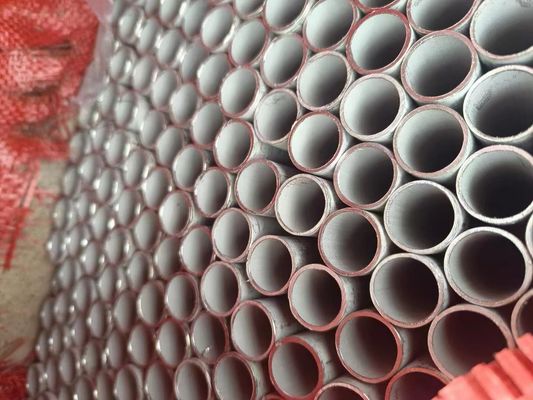

Stainless Steel Pipe Alloy 800/800H/800HT SCH40S SCH80S SCH160 SS Pipe Tube SS Tubing

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 304 304L 316L 316LN 316Ti 317L 321 310S 309S 347 2205 2507 904L 254SMO S32760 410S.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 4000-5000 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 10 Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Pipe Tube | Grade | 304 304L 410s 316L 316Ti 316ln 321 317L 2205 S32760 254smo 2507 310S 347 904L.etc |

|---|---|---|---|

| Standard | ASTM GB EN | Length | 6m Or Custom Cutting Any Length As Request |

| Diameter | DN10 - DN400 | Wall Thickness | SCH10 - XXS Or Unstandard Size |

| Type | Seamless Pipe | Service | Cutting, Polishing |

| Application | Heat Exchanger | Packing | Wooden Box Or PP Bag |

| Highlight | SCH160 Stainless Steel Pipe,SCH40S Stainless Steel Pipe,800H Stainless Steel Pipe |

||

Stainless Steel Pipe Alloy 800/800H/800HT SCH40S SCH80S SCH160 SS Pipe Tube SS Tubing

Incoloy 800 Tubing Alloy 800 Pipe ASTM B163 B407 ASME SB163 SB407 N08800 Incoloy 800 EN 10216-5 1.4558 Seamless Tubing. Incoloy 800 Tubes designed to resist Oxidation and Carburization. The general corrosion resistance is excellent. Incoloy alloy 800 is a widely used material of construction for equipment that must have high strength and oxidation resistance, carburization, and other harmful effects of high temperature exposure. (For high temperature applications requiring optimum creep and rupture properties, Incoloy alloys 800H and 800HT are used).

ASTM B163 B407 ASME SB163 SB407 N08800 Incoloy 800 Seamless Tubing is particularly useful for high-temperature equipment in the petrochemical industry because the alloy doesn’t form the embrittling sigma phase after long time exposure at 1200°F (649°C). Excellent resistance to chloride stress-corrosion cracking is another important feature of alloy 800. Alloy 800H is a solution heat treated (2100°F/1150°C), controlled-carbon version of alloy 800 with improved elevated temperature properties. It has improved creep and stress-rupture characteristics in the 1100°F (593°C) to 1800°F (982°C) temperature range.

A Ni-Cr-Fe alloy that resists high temperature oxidation. This alloy is a first choice for an upgrade from the 300 series stainless steel when improved performance or strength at temperature is required. For higher ASME Boiler and Pressure Code design values, consider Alloy 800HT.

- ASTM B163 B407 SB163 SB407 N08800 Chemical Composition

- Incoloy 800 Tubing Material Grade Comparison Chart

- ASTM B163 B407 N08800 Incoloy 800 Seamless Tubing Mechanical Properties

- Incoloy 800 Seamless Tubing Physical Properties

- Incoloy 800 Tube Standard Specification

- ASTM B163 B407 N08800 Incoloy 800 Seamless Tubing Applications

- Incoloy 800 Tubing Corrosion Resistance

- Incoloy 800 Tubing Oxidation Resistance

- Incoloy 800 Tubes Cold Working

- Incoloy 800 Seamless Tubing Annealing

- Incoloy 800 Tubing Export Countries

ASTM B163 B407 SB163 SB407 N08800 Chemical Composition

| Alloy | % | Ni | Cr | Fe | C | Mn | Si | P | Cu | S | Al | Ti |

| UNS N08800 | Min. | 30.0 | 19.0 | 0.15 | 0.15 | |||||||

| – | Max. | 35.0 | 23.0 | Rem | 0.10 | 1.50 | 1.00 | 0.75 | 0.015 | 0.60 | 0.60 | |

| EN 10216-5 1.4558 | Min. | 32.0 | 20.0 | 0.15 | 8×(C+N) | |||||||

| – | Max. | 35.0 | 23.0 | Rem | 0.030 | 1.00 | 0.70 | 0.020 | – | 0.015 | 0.45 | 0.60 |

ASTM B163 B407 ASME SB163 SB407 N0880 Incoloy 800 Seamless Tubing Chemical Composition:

| Alloy | % | Ni | Cr | Fe | C | Mn | Si | Cu | S | Al | Ti |

| 800 UNS N08800 | Min. | 30 | 19 | 0.15 | 0.15 | ||||||

| – | Max. | 35 | 23 | balance | 0.10 | 1.5 | 1 | 0.75 | 0.015 | 0.60 | 0.60 |

| 800H UNS N08810 | Min. | 30 | 19 | 0.05 | 0.15 | 0.15 | |||||

| – | Max. | 35 | 23 | balance | 0.10 | 1.5 | 1 | 0.75 | 0.015 | 0.60 | 0.60 |

| 800HT UNS N08811 | Min. | 30 | 19 | 0.06 | 0.15 | 0.15 | |||||

| – | Max. | 35 | 23 | balance | 0.10 | 1.5 | 1 | 0.75 | 0.015 | 0.60 | 0.60 |

AI+Ti: 0.85-1.20

Incoloy 800 Tubing Material Grade Comparison Chart

- UNS: N08800

- EN Number: EN 10216-5 1.4558

- EN Name: X2NiCrAlTi32-20

- W.Nr.: EN 10216-5 1.4558

- DIN: X 2 NiCrAlTi 32 20

- BS: NA15

ASTM B163 B407 N08800 Incoloy 800 Seamless Tubing Mechanical Properties

| UNS | ASTM | EN Steel No. | EN |

|---|---|---|---|

| N08800 | 800 | EN 10216-5 1.4558 | X8NiCrAlTi32-21 |

| Alloy | Form | Condition | Ultimate Tensile Strength, ksi (MPa) |

Yield Strength at 0.2% offset, ksi (MPa) |

Elongation in 2″ or 4D, percent |

| 800 | Sheet, Plate | Annealed | 85 (586) | 40 (276) | 43 |

| 800 | Sheet, Plate Strip, Bar |

Annealed | 75 (520)* | 30 (205)* | 30* |

| 800H | Sheet, Plate | SHT | 80 (552) | 35 (241) | 47 |

| 800H | Sheet, Plate Strip, Bar |

SHT | 65 (450)* | 25 (170)* | 30* |

These properties apply to both alloys

* – minimum

SHT – Solution heat-treated

Incoloy 800 Seamless Tubing Physical Properties

| Physical Properties | °F | British Units | °C | Metric Units |

| Density / Sepcific Gravity | Room | 0.287 lb./in.(3) | Room | 7.94 kg/dm³ Weight calculation factor:0.0255 |

| Electrical Resistivity |

70 200 400 600 800 |

38.9 microhm-in. 40.6 microhm-in. 43.0 microhm-in. 44.7 microhm-in. 46.1 microhm-in. |

21 93 204 316 427 |

0.989 microhm-m 1.03 microhm-m 1.09 microhm-m 1.13 microhm-m 1.17 microhm-m |

| Mean Coefficient of Thermal Expansion |

70-200 70-400 70-600 70-800 |

7.9 microin./in.-°F 8.8 microin./in.-°F 9.0 microin./in.-°F 9.2 microin./in.-°F |

21-93 21-204 21-316 21-427 |

14.2 X 10(-6)m/m-K 15.8 X 10(-6)m/m-K 16.2 X 10(-6)m/m-K 16.6 X 10(-6)m/m-K |

| Thermal Conductivity |

70 200 400 600 800 |

80 Btu-in/ft²-hr-°F 89 Btu-in/ft²-hr-°F 103 Btu-in/ft²-hr-°F 115 Btu-in/ft²-hr-°F 127 Btu-in/ft²-hr-°F |

21 93 204 316 427 |

11.5 W/m-K 12.8 W/m-K 14.8 W/m-K 16.6 W/m-K 18.3 W/m-K |

| Dynamic Modulus of Elasticity |

Room | 28.5 x 10(6) psi | Room | 196 GPa |

Incoloy 800 Tube Standard Specification

Seamless condenser and heat exchanger tubes: ASTM A213, ASTM B163, EN 10216-5

Seamless tube and pipe: ASTM A312, ASTM B407, EN 10216-5

ASME SB163 Standard Specification for Seamless Nickel and Nickel Alloy Condenser and Heat-Exchanger Tubes

ASME SB165 Standard Specification for Nickel-Copper Alloy (UNS N04400)* Seamless Pipe and Tube

ASME SB167 Standard Specification for Nickel-Chromium-Iron Alloys, Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617),and Nickel-Iron-Chromium-Tungsten Alloy (UNS N06674) Seamless Pipe and Tube

ASME SB407 Standard Specification for Nickel-Iron-Chromium Alloy Seamless Pipe and Tube

ASME SB423 Standard Specification for Nickel-Iron-Chromium-Molybdenum-Copper Alloy (UNS N08825, N08221, and N06845) Seamless Pipe and Tube

ASME SB444 Standard Specification for Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 and UNS N06852) and Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe and Tube

ASME SB622 Standard Specification for Seamless Nickel and Nickel-Cobalt Alloy Pipe and Tube

ASME SB668 UNS N08028 Seamless Pipe and Tube

ASME SB690 Standard Specification for Iron-Nickel-Chromium-Molybdenum Alloys (UNS N08366 and UNS N08367) Seamless Pipe and Tube

ASME SB729 Standard Specification for seamless UNS N08020, UNS N08026, and UNS N08024 nickel alloy pipe and Tube

EN 10216-5 Seamless steel tubes for pressure purposes

Incoloy 800 Specification:

| Bar | Pipe | Sheet | Strip | Wire | Fitting |

| ASTM B 408 & ASME SB 408 ASTM B 564 & ASME SB 564 ASME Code Case 1325 ASME Code Case 1949 ISO 9723, 9724, 9725, VdTÜV 412 & 434, DIN 17460 EN 10095 |

ASTM B 163, ASME SB 163 ASTM B 407/B 829, ASME SB 407/SB 829, ASTM B 514/B 775, ASME SB 514/SB 775, ASTM B 515/B 751, ASME SB 515/SB 751, 1325 and 1983, BS 3074NA15, SEW 470, VdTÜV 412 & 434 ISO 6207, DIN 17459 |

ASTM B409, AMS 5877, BS 3072NA15, BS 3073NA15, VdTüV 412 & 434, DIN 17460, EN 10028-7, EN 10095 | ASTM B 409/B 906, ASME SB 409/SB 906, ASME Code Case 1325, 2339 BS 3072NA15 BS 3073NA15 SEW 470, VdTÜV 412 & 434, DIN 17460, EN 10028-7 & EN 10095 |

ASTM B408, AMS 5766, ISO 9723, ISO 9724, BS 3076NA15, BS 3075NA15, EN 10095, VdTüV 412 & 434, AWS A5.11 ENiCrFe-2, AWS A5.14 ERNiCr-3 | ASTM B366 |

ASTM B163 B407 ASME SB163 SB407 N08800 Incoloy 800 Seamless Tubing Applications

ASTM B163 B407 ASME SB163 SB407 N08800 Incoloy 800 Seamless Tubing is used in a variety of applications involving exposure to corrosive environments and high temperatures. It is used for heat-treating equipment such as baskets, trays and fixtures. In chemical and petrochemical processing the alloy is used for heat exchanger and other piping systems in nitric acid media especially where resistance to chloride stress-corrosion cracking is required. In nuclear power plants, it is used for steam-generator tubing. The alloy is often used in domestic appliances for sheathing of electric heating elements. In the production of paper pulp, digester liquid heaters are often made of alloy 800. In petroleum processing , the alloy is used for heat exchanger that air-cool the process stream.

Typical applications for alloy 800 and 800H are – Heat exchangers and process piping,

- carburizing fixtures and retorts; furnace components,

- electric range heating-element sheathing

- extruded tubing for ethylene and steam methane reforming furnaces

- ammonia effluent coolers.

- Radiant syngas coolers in IGCC gasification.

- Chemical and petrochemical processing equipments

- Power generation

- Stainless Steel Reheater Tubes and Superheater Tubes

- Thermal procession fixtures

- Steel production.

Incoloy 800 Tubing Corrosion Resistance

The chromium in the alloy imparts resistance to oxidation and corrosion. The high percentage of nickel maintains an austenitic structure so that the alloy is ductile. the nickel content also contributes resistance to scaling, general corrosion, and stress-corrosion cracking. The iron content provides resistance to internal oxidation. Neither Alloy 800 nor Alloy 304 are suggested for sulfuric acid service except at lower concentrations and temperatures. UNS N08800 is highly resistant, although not totally immune, to stress corrosion cracking.

Incoloy 800 Tubes Oxidation Resistance

The alloys are particularly well suited for high temperature applications such as furnace parts and related heating equipment, for petrochemical reforming units and isocracker tubs, and for handling superheated stem in unclear and conventional power plants. With the specified high levels of chromium and nickel, the alloys offer superior resistance to oxidation and scaling, and to carburization as well.

Incoloy 800 Tubes Cold Working

Cold forming may be done using standard tooling although plain carbon tool steels are not recommended for forming as they tend to produce galling. Soft die materials (bronze, zinc alloys, etc.) minimize galling and produce good finishes, but die life is somewhat short. For long production runs the alloy tool steels ( D-2, D-3) and high-speed steels (T-1, M-2, M-10) give good results especially if hard chromium plated to reduce galling. Tooling should be such as to allow for liberal clearances and radii. Heavy duty lubricants should be used to minimize galling in all forming operations. Bending of sheet or plate through 180 degrees is generally limited to a bend radius of 1 T for material up to 1/8″ thick and 2 T for material thicker than 1/8″.

Incoloy 800 Seamless Tubing Annealing

Annealing after cold work hardening may be required. If so anneal at 1800 F for 15 minutes at temperature and air cool. Do not heat above 1800 F or grain growth will occur with degradation of strength.

![]()

![]()

![]()

![]()