-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

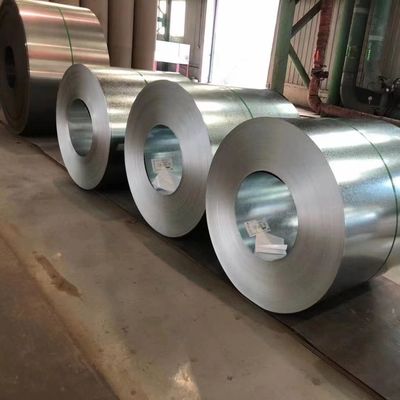

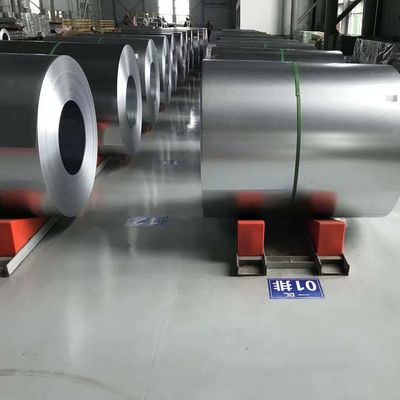

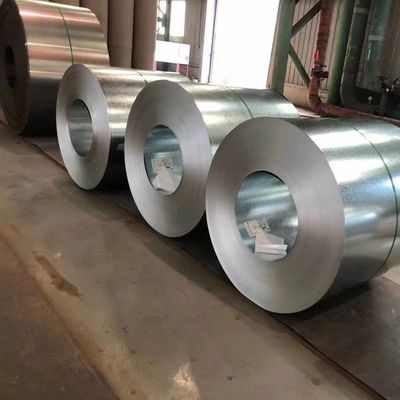

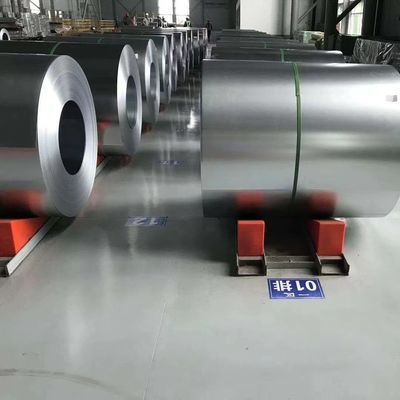

ASTM A653 Galvanized Steel Coil 0.6mm 0.8mm 1.0mm 1.2mm 1.5mm 2.0mm GI

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL WISCO |

| Certification | ISO |

| Model Number | DX51D SGCC |

| Minimum Order Quantity | 2 Ton |

| Price | 600-850 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Galvanized Steel Coil | Thickness | 0.3 - 3.0mm |

|---|---|---|---|

| Width | 1000mm 1250mm 1500mm Or As Request | Surface | Regular Spangle, Zero Spangle |

| Zinc Coating | Z40 - Z275 | Brand | BAOSTEEL ANSTEEL |

| Service | Cutting | Coil ID | 508mm |

| Highlight | ASTM A653 Galvanized Steel Coil,2.0mm GI Galvanized Steel Coil,corrosion resistance GI Galvanized Steel Coil |

||

ASTM A653 Galvanized Steel Coil Thickness 0.6mm 0.8mm 1.0mm 1.2mm 1.5mm 2.0mm GI Coils

We are one of the best galvanized steel coils suppliers and manufacturers in China, Our galvanized steel coil production line has an annual production capacity of 300,000 tons and a manufacturing speed of 150m/min. We can manufacture and sell galvanized steel coils with a width of 800-1250mm and a coating weight of 60-300g/m3. We manufacture galvanized steel coils according to EN 10346, ASTM A653 standard. We have sufficient galvanized steel coil stock for fast delivery.

Galvanized Steel Coil is used cold rolled steel coil as substrates by a continuous hot-dip process. This method tightly adheres the coating to the steel with an iron-zinc alloy bonding layer formed by a diffusion process while the heated steel strip is in contact with the molten zinc. One of the drawbacks of Galvanized is that if the Zinc coating is scratched off the steel, the Steel is left unprotected, and is subject to failure. It has excellent corrosion resistance, paintability, and workability due to zinc’s characteristics.

Surface treatment of galvanized steel coil

| Surface treatment type | Code | Feature |

|---|---|---|

| Chromic acid treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic acid treatment + oiling | S | Good corrosion resistance |

| Phosphoric acid treatment (including sealing treatment) | P | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (including sealing treatment) + oiling | Q | It has certain corrosion resistance, good paint performance, and prevents rust during transportation and storage |

| Phosphoric acid treatment (excluding sealing treatment) | T | A certain degree of corrosion resistance, good paint performance |

| Phosphoric acid treatment (excluding sealing treatment) + oiling | V | Have certain corrosion resistance, good paint performance, and prevent rust |

| Oiled | O | Prevent rust during transportation and storage |

| No treatment | M | Suitable for immediate painting |

Chromate treatment of galvanized steel coils is also called passivation treatment. Through passivation treatment, the surface structure and gloss of the galvanized layer can be improved, the corrosion resistance and service life of the galvanized layer can be improved, and the bonding force of the coating and the base metal can be improved.

The purpose of oiling galvanized steel coils is a protective layer is formed on the surface of the steel coil to prevent the surface from rusting.

American ASTM A653 standard Galvanized Steel Sheet & Coil

- Commercial Steel (CS Types A, B, and C)

Commercial Steel is a low-carbon cold-formed steel, such as galvanized steel roof forming

- Forming Steel (FS Types A and B)

Requires higher drawability than Commercial Steel, such as for lamp cover forming

- Deep Drawing Steel (DDS)

- Extra Deep Drawing Steel (EDDS)

- Structural Steel (SS) – (33,37,40,50,80)

- High Strength Low Alloy Steel (HSLAS)

European EN 10346 standard galvanized steel coil

Low carbon steel for cold forming (DX51D – DX54D)

- DX51D is equivalent to Commercial Steel, curved and profiled

- DX52D is equivalent to Forming Steel

- DX53D is equivalent to Deep Drawing Steel

- DX54D is equivalent to Extra Deep Drawing Steel

Structural Steels (S220GD – S350GD)

S220GD,S250GD,S280GD,S320GD,S350GD

Use structural steel for high load-bearing capacity, with a yield strength of 220-350

![]()

![]()

![]()

![]()