-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

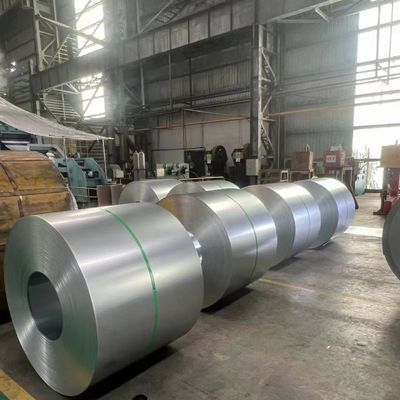

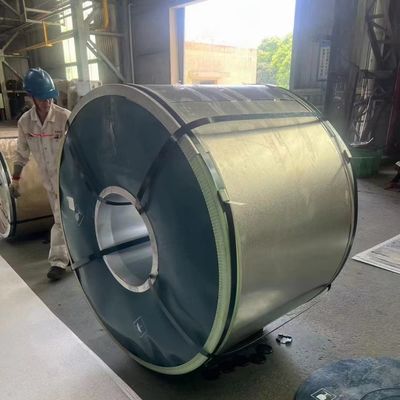

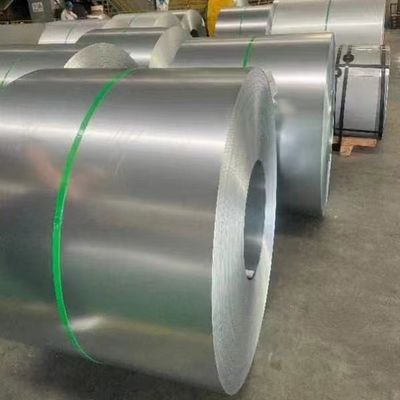

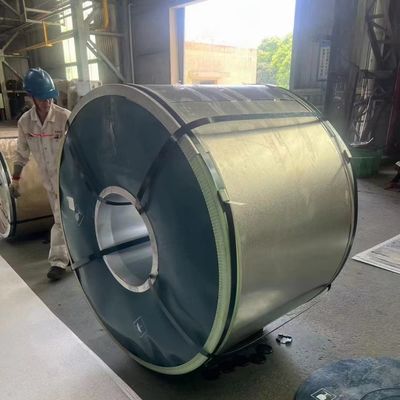

ASTM JIS Galvanized Steel Coil 0.16 - 3.0mm Z40 Hot Dipped

| Place of Origin | China |

|---|---|

| Brand Name | BAOSTEEL WISCO |

| Certification | ISO |

| Model Number | DX51D SGCC |

| Minimum Order Quantity | 2 Ton |

| Price | 600-850 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

| Products | Galvanized Steel Coil | Thickness | 0.3 - 3.0mm |

|---|---|---|---|

| Width | 1000mm 1250mm 1500mm Or As Request | Surface | Regular Spangle, Zero Spangle |

| Zinc Coating | Z40 - Z275 | Brand | BAOSTEEL ANSTEEL |

| Service | Cutting | Coil ID | 508mm |

| Highlight | ASTM JIS Galvanized Steel Coil,0.16mm Galvanized Steel Coil,Z40 Hot Dipped Galvanized Steel Coil |

||

Galvanized Steel Coil ASTM EN DIN JIS GB Standard Thickness 0.16 - 3.0mm Hot Dipped Coils

HOT DIPPED GALVANIZED STEEL COIL

| Standard | JIS / EN / ASTM Standard |

| Grades | SGCC/SGCD/SGCE,SGHC,SGC280GD/SGC340/SGC400/SGC440/SGC490/SGC570 |

| S220GD/S250GD/S280GD/S320GD/S350GD/S550GD | |

| SS230/SS250/SS275/SS340/SS380/SS410/SS480/SS550 | |

| A653 CS-A/ CS-B, ASTM A653Gr.33/Gr.37/Gr.40/Gr.50/Gr.80, | |

| DX51D/DX52D/DX53D/DX54D/DX56D etc. | |

| H220PD/H300PD/H180YD/H200YD/H260YD | |

| H180BD/H220BD/H260BD/H300BD | |

| H260LAD/H340LAD/H420LAD | |

| DP590/DP780 | |

| Coating | Z60-Z450 or G40/G60/G90/G120/G150 |

| Spangle | Regular spangle / Minimized spangle / Zero spangle |

| Sizes | Thickness:0.12mm-4.5mm Width: 900mm-1500mm |

Hot-dip galvanized steel sheet: The surface is bright and clean, excellent performance, can be used for home appliances such as automobiles, refrigerators, washing machines, as well as industrial equipment, various construction materials. Designed production capacity of 200,000 tons / continuous hot dip galvanizing production line. All use advanced production equipment. The product quality is excellent

General finished product thickness: 0.17-1.6mm, finished product width 700-1260mm. Steel coil inner diameter: 508mm, 610mm. The production unit adopts a mature galvanizing process, and selects a number of advanced and practical production technologies. The unit configuration is based on the principles of high productivity, high quality, low pollution, and low consumption. Production scale: The annual production capacity is 2.5 million tons.

The main production process flow chart: on the volume → double open roll → cut head, cut tail → welding → alkaline wash → brushing → → electrolytic cleaning → secondary brushing → hot water rinse → hot air drying → entry loop → continuous annealing → heat Dipping galvanized (ceramic zinc pot) → Air knife purging → → Air cooling after plating → Water quenching → Smoothing machine (reserved) → Tension leveler → Passivation (preservation of fingerprint resistance) → Export looper → Oiled → Sheared → Take-up → Unwinding → Weighing → Packaging.

Line performance:

(1) Double uncoiler realizes continuous production;

(2) American Steel Union galvanizing method, set up electrolytic cleaning tank, full radiant tube heating with hot tension roller to ensure advanced production of high-quality products;

(3) Passivation of roller coating to achieve zero discharge of chromium-containing waste water, and environmental protection.

(4) Advanced correction design to ensure the quality of the edge of the strip; reasonable tension segmentation, so that the unit process advantages are fully reflected; set up electrostatic oiler to ensure the quality of the final product;

(5) High quality narrow lap welding reduces the breakage rate and ensures the production efficiency of the unit;

(6) Cascade rinsing and reverse flow work methods improve strip cleanliness and greatly reduce rinsing water consumption.

(7) High-level automatic control software and HMI, screen display standard, complete information alarm system, convenient operation and maintenance. In addition to the completion of report printing and printing of the final product steel coil labels, it is also possible to complete the archiving of data, energy medium consumption and equipment status of each coil.

![]()

![]()

![]()

![]()