-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

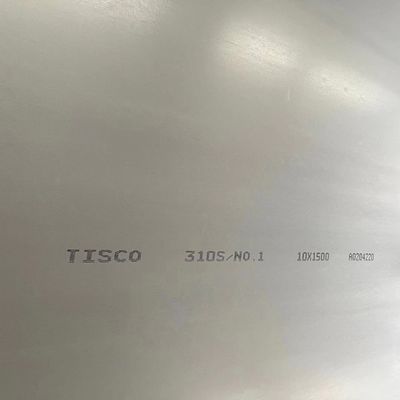

Boiler Structure Application 310S Stainless Steel Plate Thickness 3.0 - 60.0mm Hot Rolled SS Plate

| Products | Stainless Steel Plate | Grade | 310S |

|---|---|---|---|

| Thickness | 0.6 - 60.0mm | Width | 1500mm 1219mm 1000mm 2000mm |

| Surface | NO.1 2B | Brand | TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | 60.0mm Stainless Steel Plate |

||

Boiler Structure Application 310S Stainless Steel Plate Thickness 3.0 - 60.0mm Hot Rolled SS Plate

| Product Name | 310/310S Stainless Steel Plate, 310/310S Stainless Steel Sheet |

| Equivalent Grade | 310: AISI 310, UNS S31000, SAE 310, DIN 1.4841, SUS 310, X15CrNiSI25-21 |

| 310S: AISI 310S, UNS S31008, SAE 310S, DIN 1.4845, SUS 310S, X12CrNi25-21 | |

| Standard | GB, AISI, ASTM, DIN, EN, JIS |

| Process | Hot Rolled, Cold Rolled, Forged |

| Sizes | Thickness: 0.3-200mm, Width: 10-4000mm |

| Surface Treatment | NO.1, 1D, 2D, 2B, NO.4, BA, HL, Mirror, Embossim, Sandblasted |

| Fabricating | Rolling, Bending, Sllitting, Decoiling, Cutting, Drilling, Punching, Beveling, Welding etc. |

| Inspection | SGS, TUV, BV, ABS, LR etc. |

| Application | Oil&Gas, Petroleum, Vessels, Ship Building, Water Treatment And Environmental Protection etc. |

310s hot rolled stainless steel plate chemical composition

| C | Mn | P | S | Si | Cr | Ni | Mo | N | Cu | |

| 310 | 0.25 | 2.00 | 0.045 | 0.03 | 1.50 | 24.00-26.00 | 19.00-22.00 | / | / | / |

| 310S | 0.08 | 2.00 | 0.045 | 0.03 | 1.50 | 24.00-26.00 | 19.00-22.00 | / | / | / |

MECHANICAL PROPERTIES

| Tensile Strength (min) | Yield Strength (min) | Elongation | Hardness, max | ||||

| ksi | Mpa | ksi | Mpa | / | Brinell.HBW | Rockwell | |

| 310 | 75 | 515 | 30 | 205 | 40 | 217 | 95HRBW |

| 310S | 75 | 515 | 30 | 205 | 40 | 217 | 95HRBW |

Application of 310S Stainless Steel Plate

310s Hot Rolled Stainless Steel Plate is a versatile and high-performance material that is suitable for a wide range of applications. Due to its excellent resistance to oxidation and high-temperature corrosion, it is commonly used in the manufacturing of heat exchangers, furnace components, and other high-temperature applications. Here are some common applications of 310s Hot Rolled Stainless Steel Plate:

-

Heat Treatment Furnaces: 310s Hot Rolled Stainless Steel Plate is widely used in heat treatment furnaces, which require high-temperature resistance and oxidation resistance. The plates are used for making furnace components such as retorts, muffles, and radiant tubes.

-

Petrochemical Industry: The petrochemical industry involves the transportation and storage of corrosive chemicals, which require materials with high corrosion resistance. 310s Hot Rolled Stainless Steel Plate is widely used in the petrochemical industry for making storage tanks, pipelines, and other components.

-

Power Generation: 310s Hot Rolled Stainless Steel Plate is used in the power generation industry for manufacturing gas turbines, steam turbines, and other components that operate at high temperatures and pressures.

-

Aerospace Industry: The aerospace industry requires materials that are lightweight, strong, and resistant to high temperatures and corrosion. 310s Hot Rolled Stainless Steel Plate is used in the aerospace industry for manufacturing engine components, exhaust systems, and other high-temperature applications.

-

Food Processing: 310s Hot Rolled Stainless Steel Plate is commonly used in the food processing industry due to its high resistance to corrosion and easy cleanability. The plates are used for making processing equipment such as mixers, conveyors, and storage tanks.

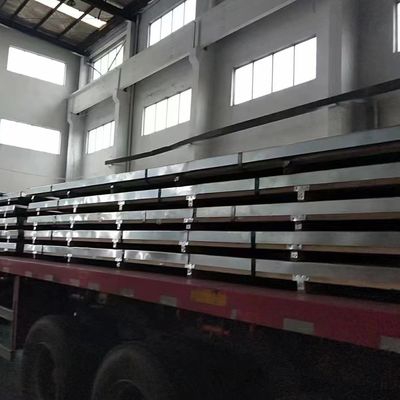

As trusted stainless steel suppliers, We provides high-quality 310s Hot Rolled Stainless Steel Plate that is suitable for a wide range of applications. Our plates are available in various sizes and thicknesses, and we can also provide customized solutions to meet your specific requirements. Contact us today for more information on our products and services.

Processing of Our Stainless Steel Plate

- Cold rolling refers to a rolling process that uses the pressure of rolls to squeeze steel to change the shape of the steel at room temperature. The advantafe of cold rolling is fast forming speed, high output, the coating is not damaged, and it can be made into a variety of cross-sectional forms to meet the needs of the use conditions. In addition, cold rolling can cause large plastic deformation of the steel, thereby increasing the yield point of the steel. Which is Widely used in home appliances and other industries.

- Hot rolling is a metalworking process. Such as steel ingots or billets are difficult to deform and process at room temperature, they are generally heated to 1100 to 1250° for rolling, this rolling process is called hot rolling. Most steel materials are rolled by hot rolling, the steel delivered in the hot-rolled state has a certain degree of corrosion resistance due to the high temperature, so it can bestored in the open air. In addition, hot rolling is that it can destroy the casting structure of the ingot, refine the grain of the steel, eliminate structural defects, make the steel structure dense, and improve the hardness of the hot rolled steel.

- According to the forging temperature, forging can be classified into hot forging, cold forging and warm forging. Hot forging is the most widely used forging process. In hot forging process, the recrystallization accompanying the high temperatures and enhanced formability enables a precise adjustment of very fine-grained microstructure. Strength-durability combinations can be specified more so than in any other forming process. Which is predominantly used for aerospace industry

Size of our 310S Stainless Steel Plate

| Thickness | Width 1000mm | Width 1219mm | Width 1500mm | Width 2000mm |

| 0.5mm | √ | √ | ||

| 0.6mm | √ | √ | ||

| 0.8mm | √ | √ | ||

| 1.0mm | √ | √ | √ | |

| 1.2mm | √ | √ | √ | |

| 1.5mm | √ | √ | √ | |

| 2.0mm | √ | √ | √ | |

| 2.5mm | √ | √ | √ | |

| 3.0mm | √ | √ | √ | √ |

| 4.0mm | √ | √ | ||

| 5.0mm | √ | √ | ||

| 6.0mm | √ | √ | ||

| 8.0mm | √ | √ | ||

|

10.0mm |

√ | √ | ||

| 12.0mm | √ | √ | ||

| 14.0mm | √ | √ | ||

| 16.0mm | √ | √ | ||

| 20.0mm-60.0mm | √ | √ |

![]()

![]()

![]()

![]()