-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

ASTM A240 Stainless Steel Checkered Plate Anti Slip Sheet AISI316L 8.0mm

| Products Name | Stainless Steel Checkered Plate | Grade | 201 304 316L.etc |

|---|---|---|---|

| Thickness | 3.0- 8.0mm | Standard | ASTM EN GB |

| Width | 1000mm 1219mm 1500mm | Surface | 2B NO.1 |

| Brand | TISCO BAOSTEEL | MOQ | 1 Ton |

| Highlight | Checkered Stainless Steel Plate Sheet,ASTM A240 Stainless Steel Checkered Plate,316L Stainless Steel Checkered Plate 8.0mm |

||

ASTM A240 AISI316L Stainless Steel Checkered Plate Anti-slip Stainless Steel Plate Sheet

- 316L stainless steel chequered plate AISI316L checked plate

- Stainless steel Panels sizes

- Material : 201,304 ,430,316,410,etc

- Thickness:1.0 - 8.0MM

Standard Size:

- 1219×2438mm (4FT×8FT)

- 1219×3048mm (4FT×10FT)

- 1000×2000mm

- 1250x2500mm

- 1500x3000mm

Surface finish:hairline HL stainless steel,no.4 stainless steel,mirror stainless steel ,color stainless steel

Stainless Checker Plate Specifications

| Item | Stainless Steel Checker Plate |

| Raw Material | Stainless steel sheet (hot rolled and cold rolled) |

| Grades | 201, 202, 301, 304, 304L, 310S, 309S, 316, 316L, 321, 409L, 410, 410S, 420, 430, 904L, etc. |

| Thickness | 1mm-10mm |

| Stock Thickness | 2mm, 2.5mm, 3mm, 3.5mm, 4mm, 4.5mm, 5mm, 5.5mm, 6mm, 7mm, 8mm |

| Width | 600mm – 1,800mm |

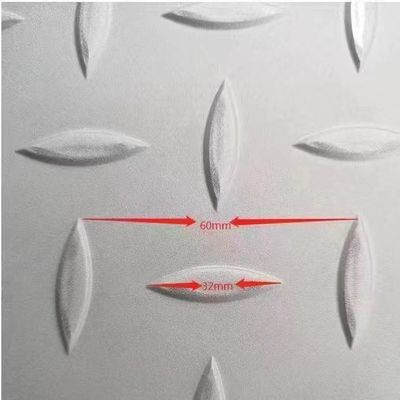

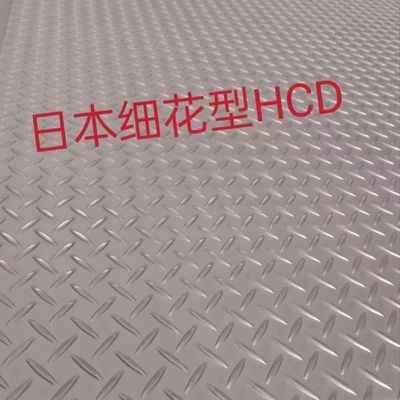

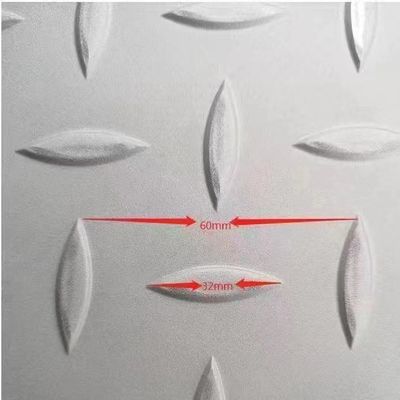

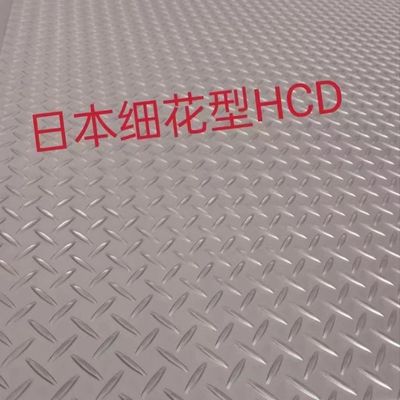

| Pattern | Chequered pattern, diamond pattern, lentils pattern, leaves pattern, etc. |

| Finish | 2B, BA, No. 1, No. 4, mirror, brush, hairline, chequered, embossed, etc. |

| Package | Standard export package |

Common Grades of Stainless steel Checker Plate

Same as other stainless steel products, the stainless steel checker plate also has many grades to choose from. Here we make a brief table sheet that introduces the common grades of the SS checked plate for you.

| American Standard | European Standard | Chinese Standard | Cr Ni Mo C Cu Mn |

| ASTM 304 | EN1.4301 | 06Cr19Ni10 | 18.2 8.1 – 0.04 – 1.5 |

| ASTM 316 | EN1.4401 | 06Cr17Ni12Mo2 | 17.2 10.2 12.1 0.04 – – |

| ASTM 316L | EN1.4404 | 022Cr17Ni12Mo2 | 17.2 10.1 2.1 0.02 – 1.5 |

| ASTM 430 | EN1.4016 | 10Cr17 | Add.188.022.6.1345 |

Advantages of Stainless Steel Checkered Sheet

1. Excellent Corrosion Resistance

The checked plate made of stainless steel is more resistant than ordinary carbon and galvanized steel sheets. Besides, the Cr element in stainless steel improves the atmospheric corrosion resistance, especially in chloride and alkaline corrosion.

2. Great Anti-slipping Performance

One of the biggest characteristics of stainless steel checker plate is that it has good anti-skid features due to concave and convex patterns. This can provide all-around traction and make it very practical.

3. High Workability

The plate is easy to weld, cut, form and machine with proper equipment. In addition, this processing procedure does not damage its mechanical properties.

4. Attractive Finish

It has high-quality modern appearance and strong metallic texture. The silver-grey finish and raised diamond pattern make it more attractive and decorative. Besides, it has many different patterns to choose from to meet different application needs.

5. Long Lifetime & Easy to Clean

It has a long lifespan of more than 50 years. Also, it is easy to clean and almost maintenance-free.

What Is Stainless Steel Checker Plate Used for?

Because of its unique features and anti-skip texture, stainless steel checker plate have a wide range of applications worldwide. Especially, it is suitable for food machinery, pharmaceutical machinery, electronic weighing, refrigerator, cold storage, buildings, packaging, transmission belts, automatic doors and car system. It includes:

1. Construction: floor decking sheets, roofing panels, wall cladding, garages, storage system, etc.

2. Industry: engineer processing, loading ramps, packing, printing, logistics equipment, etc.

3. Decoration: elevator cabs, building curtain walls, cold storage, ceilings, special ornamental projects, etc.

4. Transportation: cargo trailer, the interior of vehicles, automobile stairs, subway station, trailer beds, etc.

5. Road Protection: walkways, stair pedals, trench covers, pedestrian bridges, escalator approaches, etc.

6. Other Uses: store signs, displays, bars, toolboxes, counters, emergency fire landings, food preparation areas, dinnerware, cupboard, water heater, kitchen utensil, ship deck, etc.

What Is Stainless Steel Checker Plate?

Generally, stainless steel checker plate is made of stainless steel through embossing process. It has diamond-shaped patterns on the surface to improve its decorative effect and anti-slip performance. So it is also called diamond plate, tread plate, and chequer plate. Due to the excellent corrosion resistance and slip resistance of the SS checker plate, it has been used in many industries. The pattern design is also constantly updated and improved. There are dozens of patterns to choose from. The most popular patterns are chequered patterns, diamond patterns, lentils patterns, leaves patterns, etc.

How Is SS Checker Plate Made?

There are two different production processes. A kind of stainless steel checker plate is rolled by the rolling mill when producing stainless steel. The thickness is about 3-6mm, and it is annealed and pickled after hot rolling. The process is as follows:

Stainless steel billet → Hot rolling → Hot annealing and pickling line → Leveling machine, tension leveller, polishing line → Cross-cutting line → Hot-rolled stainless steel checkered plate.

This kind of checker plate is flat on one side and patterned on the other. It is more commonly used in the chemical industry, railway vehicles, platforms and other applications where strength is required.

The other kind of stainless steel diamond plate is made of hot-rolled or cold-rolled stainless steel by mechanical stamping. These products are concave on one side and convex on the other side. They are often used for decoration purposes.

![]()

![]()

![]()

![]()