-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

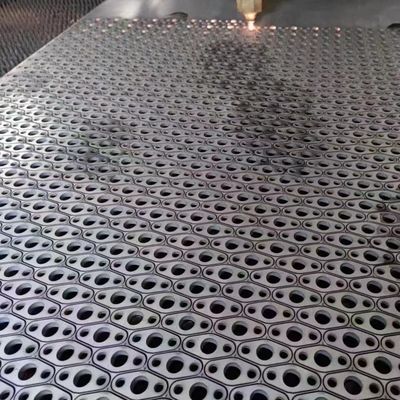

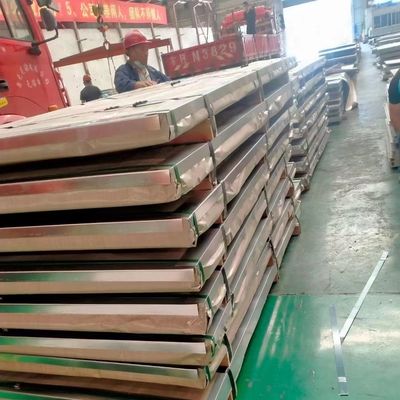

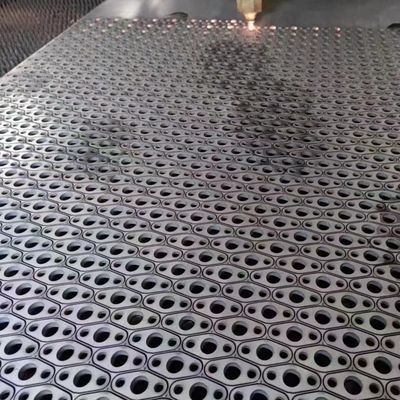

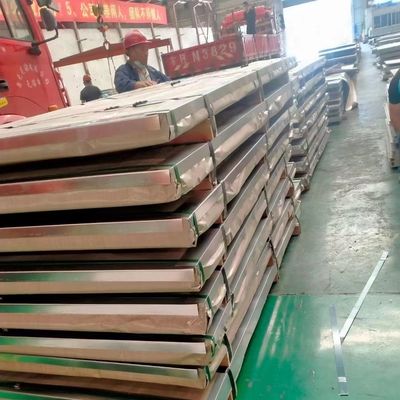

Hairline 321 310S Stainless Steel Plate Laser Cutting Hot Rolled 3.0 - 100.0mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Plate | Grade | 201 304 316L 310S 321 2205 2507.etc |

|---|---|---|---|

| Thickness | 3.0-100.0mm | Width | 1500mm 1219mm 1000mm |

| Surface | NO.1 2B | Brand | TISCO |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | Hairline Stainless Steel Plate,100.0mm Stainless Steel Plate,310S Stainless Steel Plate Laser Cutting |

||

Laser Cutting 304 316L 321 310S Stainless Steel Plate Hot Rolled 3.0 - 100.0mm SS Plate

Our Stainless Steel Sheet Specification Chart

| Description | ASTM A240 / ASME SA240 Stainless Steel Plates, ASTM A240 Hot Rolled Stainless Steel Plates |

| Standard | ASTM, ASME, BS, DIN, EN |

| Material | 310S, 310, 309, 309S, 316, 316L, 316Ti, 317, 317L, 321, 321H, 347, 347H, 304, 304L, |

| 302, 301, 201, 202, 403, 405, 409, 409L, 410, 410S, 420, 430, 631, 904L, Duplex, etc | |

| Specification | Cold rolled: 1219mm * 2438mm (4′ x 8′), 1219mm * 3048mm (4′ x 10′), 1220mm * 2440mm, 1250mm * 2500mm or as your requirement.

Hot rolled: 1500mm * 2000mm, 1000mm * 3000mm, 1500mm * 4000mm, 1500m * 6000mm or as your requiremnt. |

| Technique | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Form | Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Etc. |

| Surface | 2B, 2D, BA, NO. 1, NO. 4, NO.8, 8K, Mirror, Checkered, Embossed, Hair Line, Sand Blast, Brush, Etching |

| Service | Laser Cutting, Water Cutting, Fire Cutting, Bending |

| Thickness | 0.25-200mm, 0.3mm to 120mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, 12000mm |

| Package | Standard Export Seaworthy Package, or as required. |

| Value Added Services | Cladding,Heat Treatment,Annealed, Pickling, Polish,Rolling,Cutting,Bending,Forging,Minor Fabrication Etc. |

| MTC | Mill Test Certificate, Available as per EN 10204 3.1 |

Laser cutting stainless steel technology is to use the laser beam to irradiate a small area on the surface of the steel plate. The laser beam energy is highly concentrated to heat the stainless steel plate locally and rapidly, and the stainless steel evaporates, so as to achieve the cutting of stainless steel. Laser cutting technology has the advantages of fast cutting speed and good quality, and is widely used in various material fields.

Laser cutting stainless steel technology has many advantages. There are many methods for laser cutting stainless steel. You can add oxygen or nitrogen to the cutting section in CO2 laser. Among them, oxygen cutting will form oxide film on the cutting surface;

There is no oxide film and burr on the cutting edge with nitrogen, and no further treatment is required. Laser cutting is a very effective processing tool for cutting stainless steel sheet, which is usually less than 4mm. It can ensure good corrosion resistance of stainless steel sheet. Relatively thick plates can also be cut by laser, but the size error of the cutting parts is also increased.

The Stainless Steel Alloy Grades Of Metal Laser Cutting

Each grade of stainless steel has a slightly different chemical composition and consequently a distinct physical appearance.

The 300 series of stainless steel is the most common with 304 stainless steel and 316 stainless steel being the most prevalent grades. Two other common grades are 409 stainless steel and 430 stainless steel.

Stainless Steel Laser Cutting Services – CNC Laser Cut Stainless Steel Parts Suppliers & Manufacturer

They provide a comprehensive selection of precision laser cutting services for plate,disc, sheet,tube and more. Be-cu.com is experts in multi-axis laser cutter operations with tolerances as close as +/-.01. We use the most up-to-date CAD/CAM methods and software to produce precision-cutting components of the highest calibre and with increased efficiency.

Custom stainless steel laser cutting machines can produce surfaces with 15Ra smoothness, incredibly tight tolerances, and complicated shapes. To assist you in saving time and production costs, they can also carry out other sheet metal manufacturing processes, including cnc bending,precision welding and more.

Our Stainless Steel Laser Cutting Capabilities

Our imported equipment are known for their quick cycle times and reliably precise outcomes. We can fulfil your requirements regardless of how difficult the material or how intricate the design is.

For maximum efficiency, our machines employ modern laser head from.010″ to 4.0″, and we can work with customised pieces that are up to 127″ x 80″.Stainless steel laser cutter provide precise cuts by combining lightning-quick cutting speed with pinpoint accuracy. Capable of cutting parts from 60 to 120 in. width and 0.025 to 0.5 in. thickness. Tolerance ranges up to +/-0.009 in.

Why Use Our Stainless Steel Laser Cutting Services

The Top 6 Reasons:

- No MOQ:One-off Stainless Steel laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom Stainless Steel laser cutting process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings u0026amp; finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

The Advantage Of Stainless Steel Laser Cutting

- Thin Cutting Seam: The cutting seam of laser cutting is generally 0.1mm-0.2mm

- The Cutting Surface Is Smooth: the cutting surface of laser cutting has no burrs and no slag.

- Small Thermal Deformation: The laser processing of laser processing has thin slits, high speed and concentrated energy, so the heat transmitted to the material to be cut is small, and the deformation of the material is also very small.

- It Is Suitable For The Processing Of Large-Size Products: the mold manufacturing cost of large-size products is very high, and laser processing does not require any mold manufacturing. For this, we recommend changing the needle to one size larger, and try to adjust the feeding time of the feeding dog. Slow down, and you can fix this problem. Moreover, laser processing completely avoids the slump formed when the material is punched and sheared, which can greatly reduce the production cost of the enterprise and improve the grade of the product.

- It Is Very Suitable For The Development Of New Products And Shortens The Research And Development Cycle: once the product drawings are formed, laser processing can be carried out immediately, and you can get the physical objects of the new products in the shortest time.

- Material Saving: laser processing adopts computer programming, laser equipment can cut different shapes of products, and different combinations of upper and lower thread thicknesses of the interlock sewing machine will definitely produce different sewing effects. Under normal circumstances, the upper and lower lines should be the same thickness.

![]()

![]()

![]()

![]()