-

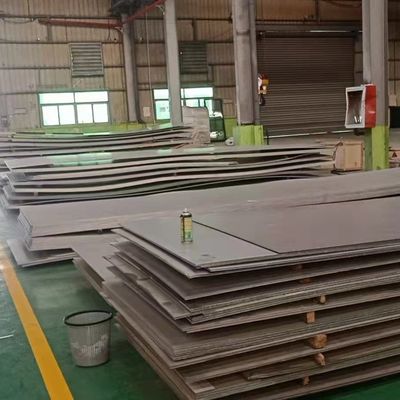

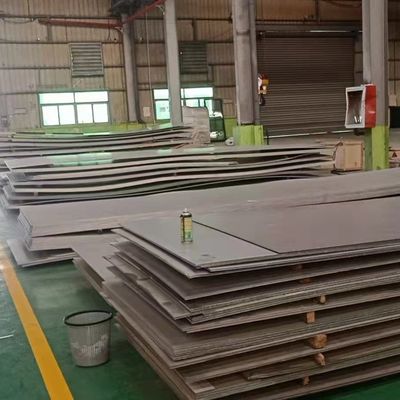

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

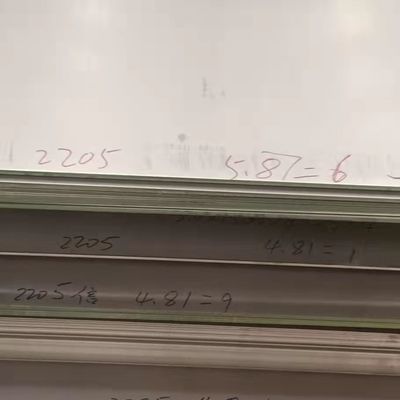

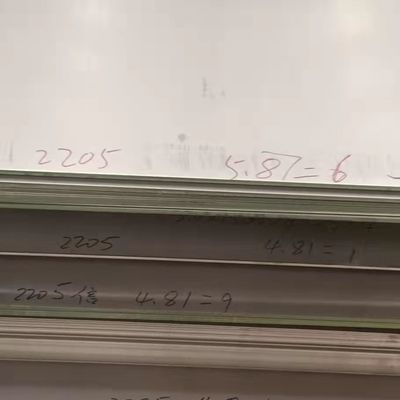

201 Stainless Steel Sheet and Plate BAOSTEEL 201 Stainless Steel SS Plate 0.3 - 16.0mm in Stock

| Products | Stainless Steel Plate | Grade | 201 |

|---|---|---|---|

| Thickness | 0.4-16.0mm | Width | 1500mm 1219mm 1000mm |

| Surface | NO.1 2B | Brand | BAOSTEEL |

| Standard | ASTM A240/240M | Loading Port | Shanghai Port |

| Highlight | BAOSTEEL 201 Stainless Steel Plate,201 Stainless Steel Plate |

||

201 Stainless Steel Sheet and Plate BAOSTEEL 201 Stainless Steel SS Plate 0.3 - 16.0mm in Stock

| Product Name | 201 Stainless Steel Sheet & Plate |

| Thinckness |

Cold rolled:0.3mm-3mm Hot rolled: 3.0mm-80mm |

| Standard Size | Cold Rolled 1000*2000mm 1219*2438mm 1500*3000mm |

| Hot Rolled 1500*6000mm 1800*6000mm 2000*6000mm | |

| Service | Cutting (laser cutting, plasma cutting, cutting machine), Bending |

| Surface Service | Raw finishing (2B NO.1) Finishing(HL 8K Checkered.etc) |

| Standard | ASTM, AISI, DIN, EN, GB, JIS |

| Mainly Grade |

200 series: 201, 202 300 series: 301 304 309S 310S 316L 316Ti 317L 321 347 400 series: 409, 409L, 410, 420, 430, 431, 439,441 , 443 , 444 |

| Brand | TISCO BAOSTEEL ZPSS LISCO JISCO |

| Application range | Decoration, Industry ,Kitchenwave ,Building, Elevator |

What Is Type 201 Stainless Steel?

Type 201 stainless steel is an alloy that contains half the nickel and more manganese and nitrogen than other popular steels. While it is less expensive than some other alloys (because of its low nickel content), it is not as easy to work or form. Type 201 is an austenitic metal because it is non-magnetic stainless steel that contains high levels of chromium and nickel and low levels of carbon.

Facts About Type 201 Stainless Steel

Type 201 stainless steel is a mid-range product with a variety of useful qualities. While it is ideal for certain uses, it is not a good choice for structures that may be prone to corrosive forces such as saltwater.

- Type 201 is part of the 200 series of austenitic stainless steel. Originally developed to conserve nickel, this family of stainless steels is characterized by low nickel content.

- Type 201 can substitute for type 301 in many applications, but it's less resistant to corrosion than its counterpart, particularly in chemical environments.

- Annealed, it is non-magnetic, but type 201 can become magnetic by cold working. Greater nitrogen content in type 201 provides higher yield strength and toughness than type 301 steel, especially at low temperatures.

- Type 201 is not hardened by heat treatment and is annealed at 1850-1950 degrees Fahrenheit (1010-1066 degrees Celsius), followed by water quenching or rapid air cooling.

- Type 201 is used to produce a range of household appliances, including sinks, cooking utensils, washing machines, windows, and doors. It is also used in automotive trim, decorative architecture, railway cars, trailers, and clamps. It is not recommended for structural outdoor applications because of its susceptibility to pitting and crevice corrosion.

Type 201 Stainless Steel Composition and Properties

The qualities of type 201 stainless steel are as follows:

Density (pounds/inches3): 0.283

Modulus of elasticity in tension (pounds per inches2 x 106): 28.6

Specific heat (BTU/pounds/degrees Fahrenheit): 0.12 at 32-212 degrees Fahrenheit

Thermal conductivity (BTU/hr./ft./degrees Fahrenheit): 9.4 at 212 degrees Fahrenheit

Melting point range: 2550-2650 degrees Fahrenheit

ElementType 201 (Wt.%)

- Carbon: 0.15 max

- Manganese: 5.50-7.50 max.

- Phosphorus: 0.06 max.

- Sulfur: 0.03 max.

- Silicon 1.00 max.

- Chromium: 16.00-18.00

- Nickel: 0.8-1.20

- Nitrogen: 0.25 max.

- Iron: Balance

Processing and Forming

Type 201 stainless cannot be hardened by heat treatment, but it can be hardened by cold working. Type 201 can be annealed at temperatures between 1,010 and 1,093 degrees Celsius (1,850 and 2,000 degrees Fahrenheit). In order to keep carbides in solution and avoid sensitization, rapid cooling through the carbide precipitation range 815 and 426 degrees Celsius (1,500 and 800 degrees Fahrenheit) is required.

This grade of stainless can be both formed and drawn. Intermediate annealing may be required for severe operations as a result of type 201's high work-hardening rate.

Type 201 stainless can be welded by all standard methods used for 18% chromium and 8% nickel stainless steels, however, inter-granular corrosion can impact the heat zone if carbon content exceeds 0.03%.

![]()

![]()

![]()

![]()