-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

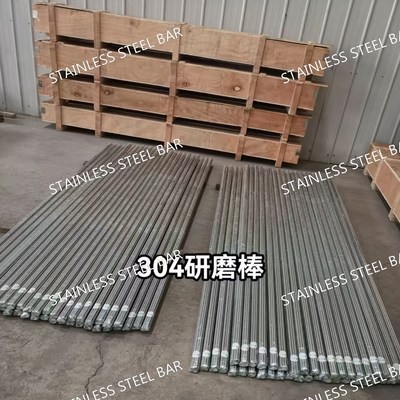

High-Quality 304F Stainless Steel Ground Bar for CNC and Tooling Apps

| Lugar de origem | China |

|---|---|

| Marca | Delta |

| Certificação | ISO 9001 |

| Número do modelo | 304F |

| Quantidade de ordem mínima | 500 kgs |

| Preço | 1.8-3.5 USD/Kg |

| Detalhes da embalagem | Caixa de madeira ou papel resistente à água |

| Tempo de entrega | 5 - 10 dias |

| Termos de pagamento | T/T, União Ocidental |

| Habilidade da fonte | De 50 toneladas pelo mês |

| Nome dos produtos | Barra de aço inoxidável 304F | Diâmetro | 10 - 350mm |

|---|---|---|---|

| Comprimento | 6m ou cortando qualquer comprimento conforme solicitação | Superfície | Decapado ou Brilhante |

| Serviço | Corte | Padrão | ASTM DIN GB EN |

| Outros produtos | Barra redonda, barra quadrada, barra plana.etc | Técnica | Enrolado a quente |

| Destacar | Barras de moagem de aço inoxidável 304F,Barras de aço inoxidável para ferramentas CNC,barra de aço inoxidável com garantia |

||

High-Quality 304F Stainless Steel Ground Bar for CNC and Tooling Apps

Especificação dos produtos

| Nome dos produtos | Barras redondas de aço inoxidável 304F |

| Grau |

303,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660C276,600,601,625,718,800800H,825,926etc. |

| Produtos Gama de diâmetros | φ3 mm - φ350 mm |

| Duração | 6 m/pcs ou cortando qualquer comprimento conforme pedido |

| Superfície | Finalização de decapagem, acabamento brilhante |

| Padrão | ASTM JIS, GB, DIN EN |

| Serviço | Cortar |

| Outra forma | Quadrado, plano, hexagonal, redondo, etc. |

| Porto de carga | Porto de Xangai |

| MOQ | 500 kg |

High-Quality 304F Stainless Steel Ground Bar for CNC and Tooling Apps

Visão geral do produto

O...Barras de moagem de aço inoxidável 304Fé projetado para aplicações de alta precisão onde o acabamento da superfície, resistência à corrosão e excelente maquinariabilidade são essenciais.304F é projetado para fornecer uma maquinabilidade superior, mantendo a excelente resistência à corrosão e durabilidade do aço inoxidável padrão 304.

Estas barras de moagem são ideais para usinagem CNC, ferramentas e engenharia de precisão.e reduz a necessidade de operações de acabamento pós-máquinaIndústrias como automotiva, aeroespacial, médica, processamento de alimentos e fabricação química comumente utilizam barras de moagem 304F para aplicações de alto desempenho.

Especificações técnicas

| Parâmetro | Especificações |

|---|---|

| Materiais | Aço inoxidável 304F (liga 304F) |

| Faixa de diâmetro | 3 mm 120 mm (diâmetros personalizados disponíveis) |

| Duração | Até 6 metros (longitudes personalizadas a pedido) |

| Acaba. | Terreno de precisão |

| Densidade | 70,93 g/cm3 |

| Resistência à tração | ≥ 505 MPa |

| Força de rendimento | ≥ 210 MPa |

| Extensão | ≥ 40% |

| Dureza (Brinell) | 201 HB |

| Conductividade térmica | 16.2 W/m·K |

| Resistividade elétrica | 00,73 x 10−6 Ω·m |

| Roughness da superfície (Ra) | ≤ 1,0 μm |

| Máquinabilidade | Excelente (enriquecido em enxofre) |

Composição química

| Elementos | Teor (%) |

|---|---|

| Carbono (C) | 0.08 máximo |

| Manganês (Mn) | 2.00 no máximo |

| Fósforo (P) | 0.045 no máximo |

| Enxofre (S) | 0.20 ¢ 0.35 |

| Silício (Si) | 1.00 no máximo |

| Cromo (Cr) | 18.0 ¢ 20.0 |

| Níquel (Ni) | 8.0 ¢ 10.5 |

| Ferro (Fe) | Balanço |

O teor de enxofre melhora a maquinabilidade, mantendo a resistência à corrosão, tornando o 304F ideal para aplicações de usinagem CNC e ferramentas.

Propriedades mecânicas

| Imóveis | Valor |

|---|---|

| Resistência à tração | ≥ 505 MPa |

| Força de rendimento | ≥ 210 MPa |

| Extensão | ≥ 40% |

| Dureza de Brinell (HB) | 201 |

| Modulo de Elasticidade | 193 GPa |

Essas propriedades mecânicas garantem durabilidade, confiabilidade e desempenho consistente em várias condições operacionais.

Normas e Certificações

-

ASTM A276Barras e formas de aço inoxidável

-

ASTM A479Barras de aço inoxidável para recipientes sob pressão

-

A norma UNS S30420Sistema de numeração unificado para o 304F

-

ISO 9001:2015¢ Conformidade com a gestão da qualidade

-

ISO 14001:2015¢ Conformidade com a gestão ambiental

Características fundamentais

-

Alta maquinabilidadeO 304F reforçado com enxofre permite uma usinagem CNC mais rápida e um menor desgaste das ferramentas.

-

Resistência à corrosão¢ Mantém a excelente resistência à corrosão do aço inoxidável 304 para aplicações interiores e exteriores.

-

Precision Ground FinishA superfície lisa reduz o acabamento pós-máquina, garantindo uma alta precisão da peça.

-

Não magnético em estado de recozimento¢ Ideal para aplicações em electrónica e equipamentos sensíveis.

-

Durável e confiávelA sua elevada resistência à tração e alongamento asseguram um desempenho a longo prazo.

-

Aplicações versáteisAdequado para indústrias automotiva, aeroespacial, médica, alimentar e química.

Graus de aço inoxidável comparáveis

| Grau | Máquinabilidade | Resistência à corrosão | Notas |

|---|---|---|---|

| 304 | Moderado | Excelente. | Padrão 304, menos maquinável que o 304F |

| 303 | Excelente. | Moderado | Alta maquinariabilidade, menor resistência à corrosão |

| 316F | Muito bem. | Excelente (marinha) | Versão maquinável do 316, para ambientes adversos |

| 430 | É justo. | Moderado | Ferrítico, magnético, menor resistência à corrosão |

Aplicações

-

Automóveis: eixos, fixações, pinos e conectores para veículos

-

Aeronáutica: Buchas de precisão, alfinetes e pequenos componentes estruturais

-

Medicina e cuidados de saúde: Instrumentos cirúrgicos, implantes, conectores

-

Processamento de alimentos: Partes de máquinas, componentes de transportadores, bombas e válvulas

-

Ferramentas e máquinas: Engrenagens, matrizes, fendões e ferramentas de precisão

-

Indústria química: Tubos, acessórios e recipientes expostos a substâncias químicas leves

-

EletrónicaPartes e caixas não magnéticas

Perguntas frequentes

P1: Como é que o 304F é diferente do aço inoxidável padrão 304?

A1:O 304F contém enxofre adicional, o que aumenta a maquinabilidade, permitindo uma usinagem mais rápida e uma vida útil mais longa da ferramenta, mantendo a resistência à corrosão.

P2: As barras de moagem 304F podem ser soldadas?

A2:Sim, podem ser soldados, por isso, use metais de preenchimento compatíveis e considere a possibilidade de recozimento pós-soldado para minimizar o estresse e manter a resistência à corrosão.

Q3: Que acabamento de superfície é fornecido nas barras?

A3:As barras são moídas de precisão com uma rugosidade de superfície típica Ra ≤ 1,0 μm, adequadas para aplicações CNC e ferramentas.

P4: São as barras 304F adequadas para aplicações alimentares e médicas?

A4:Sim, o aço inoxidável 304F é biocompativel, resistente à corrosão e fácil de limpar, tornando-o adequado para alimentos e equipamentos médicos.

P5: O 304F pode ser tratado termicamente para aumentar a dureza?

A5:Não, como um aço inoxidável austenítico, o 304F não pode ser endurecido por tratamento térmico, mas pode ser aquecido para aliviar o estresse ou amolecer para formar.

Conclusão

O...Barras de moagem de aço inoxidável 304Ffornece uma combinação única dealta maquinabilidade, resistência à corrosão e acabamento de solo de precisãoA sua composição reforçada em enxofre reduz o desgaste da ferramenta, melhora a eficiência de fabrico e garante um desempenho consistente.Adequado a todas as indústrias, incluindo a automóvel, aeroespacial, médico, processamento de alimentos e fabricação química, 304F barras de terra ofertaprecisão, durabilidade e confiabilidadepara necessidades de engenharia e fabricação de alto desempenho.

![]()

![]()

![]()

![]()