-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

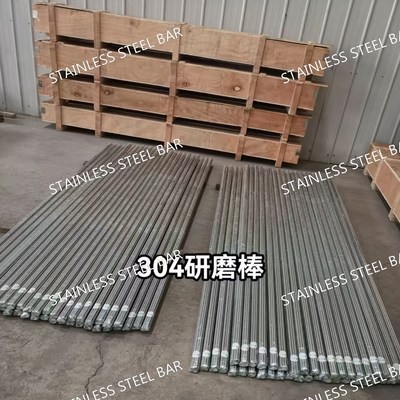

고품질의 304F 스테인리스 스틸 마운드 바 CNC 및 도구 응용 프로그램

| 제품 이름 | 304F 스테인레스 스틸 바 | 지름 | 10 - 350 밀리미터 |

|---|---|---|---|

| 길이 | 6m 또는 요청에 따라 길이를 절단합니다 | 표면 | 산세 또는 밝은 |

| 서비스 | 절단 | 기준 | ASTM DIN GB EN |

| 다른 제품 | 둥근 바, 사각형 바, 플랫 바 .etc | 기술 | 뜨거운 롤 |

| 강조하다 | 304F 스테인리스강 접지 바,CNC 도구 스테인리스 스틸 막대,보증이 있는 스테인리스강 바 |

||

고품질의 304F 스테인리스 스틸 마운드 바 CNC 및 도구 응용 프로그램

제품 사양

| 제품 이름 | 304F 스테인리스 스틸 원형 막대 |

| 등급 |

303,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C2205,2507904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660C276600,601,625,718,800800H,825,926등등 |

| 제품 지름 범위 | φ3mm - φ350mm |

| 길이 | 6m/pcs 또는 요청에 따라 어떤 길이나 절단 |

| 표면 | 피클링 마감, 밝은 마감 |

| 표준 | ASTM JIS,GB,DIN EN |

| 서비스 | 절단 |

| 다른 형태 | 사각형, 평면, 육각형, 둥근 등 |

| 로딩 포트 | 상하이 항구 |

| MOQ | 500kg |

고품질의 304F 스테인리스 스틸 마운드 바 CNC 및 도구 응용 프로그램

제품 개요

The304F 스테인리스 스틸 마운드 바고 정밀 애플리케이션을 위해 설계되었습니다. 표면 마감, 부식 저항, 그리고 우수한 가공성이 필수적입니다.304F는 표준 304 스테인리스 스틸의 우수한 부식 저항과 내구성을 유지하면서 우수한 가공성을 제공하기 위해 설계되었습니다..

이 마운드 바는 CNC 가공, 도구 및 정밀 엔지니어링에 이상적입니다. 부드러운 마운드 표면은 가공 중에 마찰을 최소화하고 부품 정확성을 향상시킵니다.가공 후 가공 작업의 필요성을 줄이고자동차, 항공우주, 의료, 식품 가공 및 화학 제조업 등 산업은 일반적으로 고성능 애플리케이션을 위해 304F ग्राउंड 바를 사용합니다.

기술 사양

| 매개 변수 | 사양 |

|---|---|

| 소재 | 304F 스테인리스 스틸 (연금 304F) |

| 지름 범위 | 3mm 120mm (개인 맞춤 직경) |

| 길이 | 최대 6m (요청에 따라 사용자 정의 길이) |

| 끝내 | 정밀지 |

| 밀도 | 7.93g/cm3 |

| 팽창 강도 | ≥505 MPa |

| 생산력 | ≥210 MPa |

| 길쭉함 | ≥40% |

| 강도 (Brinell) | 201 HB |

| 열전도성 | 16.2 W/m·K |

| 전기 저항성 | 00.73 x 10−6 Ω·m |

| 표면 거칠성 (Ra) | ≤1.0 μm |

| 가공 능력 | 훌륭하다 (황이 더 많이 들어있다) |

화학적 성분

| 원소 | 함유량 (%) |

|---|---|

| 탄소 (C) | 0.08 최대 |

| 망간 (Mn) | 2.00 최대 |

| 포스포스 (P) | 00.045 최대 |

| 황 (S) | 00.20 ∼ 0.35 |

| 실리콘 (Si) | 1.00 최대 |

| 크롬 (Cr) | 180.0 ∼ 20.0 |

| 니켈 (Ni) | 80.0 105 |

| 철 (Fe) | 재고 |

황 함량은 경화 저항성을 유지하면서 가공성을 향상시켜 CNC 가공 및 도구 응용 프로그램에 이상적인 304F를 만듭니다.

기계적 특성

| 재산 | 가치 |

|---|---|

| 팽창 강도 | ≥505 MPa |

| 생산력 | ≥210 MPa |

| 길쭉함 | ≥40% |

| 브리넬 강도 (HB) | 201 |

| 탄력성 모듈 | 193 GPa |

이 기계적 특성 은 다양한 운영 조건 하 에서 내구성, 신뢰성, 그리고 일관성 있는 성능을 보장 합니다.

표준 및 인증

-

ASTM A276✅ 스테인레스 스틸 막대 및 모양

-

ASTM A479압력 용기용 스테인레스 스틸 막대

-

UNS S30420304F에 대한 통일 번호 시스템

-

ISO 9001:2015품질 관리 준수

-

ISO 14001:2015환경 관리 준수

주요 특징

-

높은 가공성황이 증가 한 304F는 더 빠른 CNC 가공과 도구 마모를 줄일 수 있습니다.

-

부식 저항성304 스테인리스 스틸의 뛰어난 부식 저항성을 유지합니다.

-

정밀 마감부드러운 표면은 높은 부품 정확성을 보장하는 후 가공 마무리 작업을 줄입니다.

-

소화 상태에서 자기적이지 않음전자 및 민감한 장비 응용을위한 이상적입니다.

-

내구성 있고 신뢰성● 높은 팽창 강도와 연장력 은 장기적 성능 을 보장 합니다.

-

다양 한 적용 방법자동차, 항공우주, 의료, 식품 및 화학 산업에 적합합니다.

비교 가능한 스테인리스 스틸 등급

| 등급 | 가공 능력 | 부식 저항성 | 참고문서 |

|---|---|---|---|

| 304 | 중간 | 훌륭해요 | 표준 304, 304F보다 더 낮은 가공성 |

| 303 | 훌륭해요 | 중간 | 높은 가공 가능성, 덜 부식 저항성 |

| 316F | 좋아 | 훌륭합니다 (마린) | 316의 가공 가능한 버전, 혹독한 환경에 |

| 430 | 공평하다 | 중간 | 페리트, 자기성, 경화 저항성이 낮다 |

신청서

-

자동차: 차량용 셰프트, 고정장치, 핀 및 커넥터

-

항공우주: 정밀 부싱, 핀 및 작은 구조 부품

-

의료 및 건강 관리: 외과기, 임플란트, 연결기

-

식품 가공: 기계 부품, 컨베이어 부품, 펌프 및 밸브

-

도구 및 기계: 기어, 도형, 스핀들, 정밀 도구

-

화학 산업: 가벼운 화학물질에 노출된 파이프, 피팅 및 용기

-

전자제품: 비마그네틱 부품 및 가구

FAQ

Q1: 304F는 표준 304 스테인리스 스틸과 어떻게 다릅니다?

A1:304F에는 추가적 인 황이 포함되어 있으며, 가공성을 향상시켜 더 빠른 가공과 더 긴 도구 수명을 허용하면서 부식 저항성을 유지합니다.

Q2: 304F 마운드 바가 용접 될 수 있습니까?

A2:예, 용접 할 수 있습니다. 용접 후 용접 을 고려 하여 용접 을 최소화 하고 부식 저항성 을 유지 하기 위해 호환 된 채식 금속 을 사용 하십시오.

Q3: 바에 어떤 표면 가공이 제공됩니다?

A3:막대는 정밀 밀링으로, 전형적인 표면 거름 Ra ≤1.0μm, CNC 및 도구 응용에 적합합니다.

Q4: 304F 바는 식품 및 의료용으로 적합합니까?

A4:네, 304F 스테인리스 스틸은 생물 호환성 있고, 부식 저항성 있고, 청소가 쉽기 때문에 식품과 의료 장비에 적합합니다.

Q5: 304F는 단단성을 높이기 위해 열처리를 할 수 있습니까?

A5:아뇨, 아우스테니트성 스테인리스 스틸로서 304F는 열처리로 굳게 만들 수는 없지만, 스트레스를 완화하기 위해 앙일링하거나 폼을 만들기 위해 부드럽게 만들 수 있습니다.

결론

The304F 스테인리스 스틸 마운드 바독특한 조합을 제공합니다.높은 가공성, 부식 저항성, 정밀 마운드 마무리, 그것은 CNC 가공 및 도구 응용 프로그램에 이상적입니다. 그 황 강화 된 구성은 도구 마모를 줄이고 제조 효율성을 향상시키고 일관된 성능을 보장합니다.자동차 산업을 포함한 모든 산업에 적합합니다., 항공우주, 의료, 식품 가공 및 화학 제조, 304F 바닥 바 제공정확성, 내구성, 신뢰성고성능 엔지니어링 및 제조 필요에

![]()

![]()

![]()

![]()