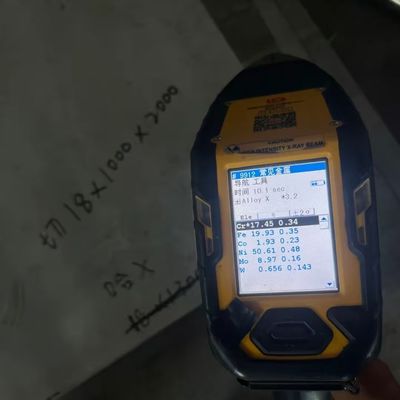

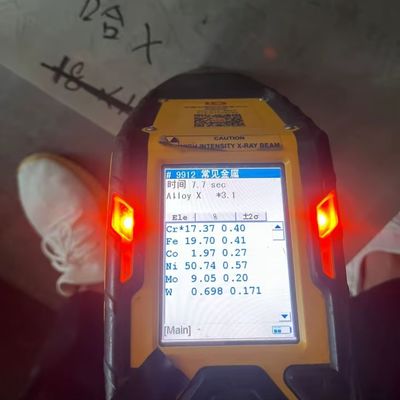

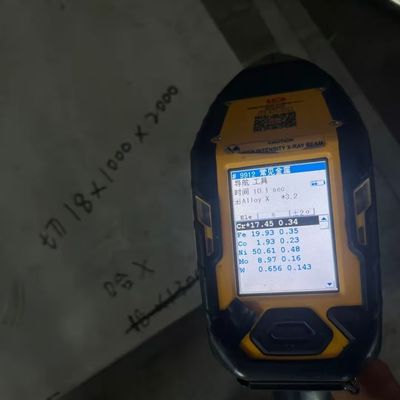

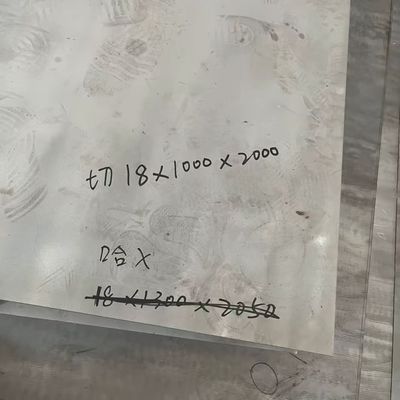

Hastelloy X Nickel Alloy Plate Thickness 1.0 - 40.0mm | Alloy X Plate | HX Plate

Product Overview

Hastelloy X (UNS N06002) is a solid-solution-strengthened nickel-chromium-iron-molybdenum alloy that offers an exceptional combination of oxidation resistance, high-temperature strength, and excellent fabricability. Known commercially as Alloy X or HX, it is one of the most widely used high-temperature nickel-based alloys in the aerospace, chemical processing, and industrial furnace industries.

Our Hastelloy X Nickel Alloy Plates, available in thicknesses ranging from 1.0 mm to 40.0 mm, are manufactured to strict quality standards to ensure reliability and long service life in demanding environments. The material can be cut, formed, and welded with ease, and it performs remarkably well under cyclic thermal conditions, oxidation, and carburization.

Key Features and Benefits

-

Outstanding Oxidation Resistance

Hastelloy X exhibits excellent resistance to oxidation and scaling up to approximately 1200°C (2200°F). It maintains a tightly adherent oxide layer that protects the base metal during prolonged exposure to high temperatures, making it ideal for furnace components and combustion systems. -

High Strength at Elevated Temperatures

With superior creep and rupture strength, Alloy X retains its mechanical integrity under long-term exposure to high stress and temperature conditions. This makes it suitable for turbine engines, hot gas ducts, and industrial heaters. -

Excellent Fabricability and Weldability

Unlike many high-temperature alloys, Hastelloy X can be readily fabricated by standard forming and machining techniques. It can also be welded by TIG, MIG, and resistance welding methods without post-weld cracking or loss of corrosion resistance. -

Good Resistance to Carburization and Nitriding

In reducing atmospheres that contain carbon or nitrogen, Alloy X demonstrates resistance to carburization and nitriding, maintaining surface stability and mechanical strength. -

Versatility in Harsh Environments

Beyond oxidation resistance, Hastelloy X performs well in oxidizing, carburizing, and neutral atmospheres, as well as in limited reducing conditions. It is used extensively in furnace rolls, muffles, combustion cans, and heat-treatment fixtures.

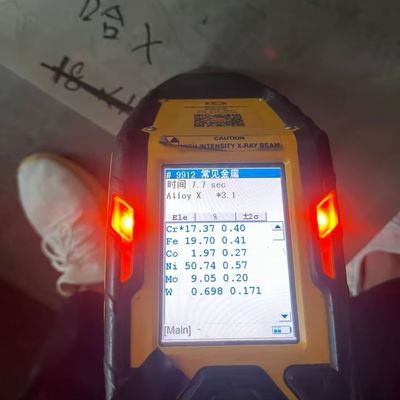

Chemical Composition (Typical, %)

| Element | Ni | Cr | Fe | Mo | Co | W | Mn | Si | C | P | S |

|----------|----|----|----|----|----|----|----|----|----|----|

| Content | Balance | 21.0 | 18.0 | 9.0 | 1.5 | 0.6 | ≤1.0 | ≤1.0 | 0.10 | ≤0.04 | ≤0.03 |

This balanced composition provides a strong combination of oxidation resistance, ductility, and toughness, even after long exposure to high temperatures.

Mechanical Properties (Typical at Room Temperature)

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | ≥ 690 MPa | ≥ 100,000 psi |

| Yield Strength (0.2% Offset) | ≥ 275 MPa | ≥ 40,000 psi |

| Elongation | ≥ 40% | ≥ 40% |

| Hardness (Brinell) | ~160 HB | ~160 HB |

At elevated temperatures (up to 800°C), the alloy retains high tensile and creep-rupture strength, ensuring reliable performance in thermally stressed applications.

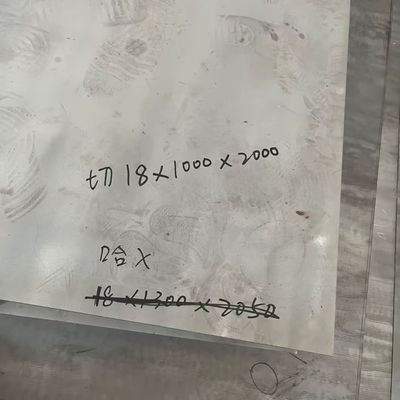

Available Dimensions and Forms

-

Thickness: 1.0 mm – 40.0 mm

-

Width: Up to 2000 mm

-

Length: Up to 6000 mm (custom lengths available)

-

Standards: ASTM B435, AMS 5536, ASME SB435

-

Form: Hot rolled plate, cold rolled sheet, precision cut plate, or custom machined parts

We also offer laser cutting, plasma cutting, and waterjet cutting services, providing plates and blanks to exact customer-specified dimensions with high edge quality and minimal thermal distortion.

Heat Treatment and Fabrication

Hastelloy X is typically supplied in the solution-annealed condition (at 1175°C followed by rapid cooling). This condition optimizes both ductility and corrosion resistance, making it ready for forming, deep drawing, or machining.

The alloy can be readily cold-worked and hot-worked using standard nickel alloy practices. It is particularly well-suited for TIG and MIG welding, with filler metals such as ERNiCrMo-2 or similar grades recommended for joining.

Post-weld annealing is not usually required for most applications but can be applied to restore full ductility when components are heavily formed or cold worked.

Corrosion and Oxidation Resistance

Hastelloy X has been extensively tested for corrosion resistance in a wide range of high-temperature oxidizing and reducing environments. It shows:

-

Excellent oxidation resistance in air at 1200°C (2200°F)

-

Good resistance to carburization and chloride-induced corrosion

-

Stable performance in mixed gas environments containing sulfur compounds

Due to these properties, it is one of the preferred materials for components exposed to combustion gas atmospheres or heat-treatment environments.

Applications

Hastelloy X is a versatile high-temperature alloy used across multiple industries where thermal stability, oxidation resistance, and strength are critical:

-

Aerospace and Jet Engines:

-

Combustion chambers, transition ducts, and afterburner components

-

Turbine exhaust and nozzle parts

-

-

Industrial Furnaces:

-

Furnace muffles, rollers, and trays

-

Heat-treatment fixtures and retorts

-

-

Chemical Processing:

-

Catalyst support grids, reformer tubes, and heat exchangers

-

Components exposed to hot gases or corrosive vapors

-

-

Power Generation and Energy:

-

Gas turbine combustion liners

-

Heat recovery and waste incineration systems

-

-

Automotive and Environmental Systems:

-

Turbocharger components and exhaust manifolds

-

Flue gas scrubbers and incineration systems

-

Wherever high temperature and corrosion resistance are required simultaneously, Hastelloy X stands as a material of choice.

Processing and Customization Services

Our manufacturing facilities are equipped to provide custom processing according to your project needs:

-

Laser Cutting / Waterjet Cutting / Plasma Cutting

-

CNC Machining and Drilling

-

Surface Polishing and Pickling

-

Heat Treatment and Annealing

-

Precision Blanking and Forming

We deliver plates with smooth edges, consistent flatness, and dimensional accuracy. Each plate is thoroughly inspected using ultrasonic and visual examination methods to ensure premium quality and performance.

Quality Assurance

All Hastelloy X plates are produced under ISO 9001:2015-certified quality management systems. Material test certificates (MTC) are provided in accordance with EN 10204 3.1, detailing chemical composition, mechanical properties, and heat treatment records.

We ensure full traceability from the melt to the finished plate, providing confidence for critical applications in aerospace, petrochemical, and energy industries.

Packaging and Delivery

Each Hastelloy X plate is securely packed to prevent surface damage and contamination during transit. Depending on order size, packaging includes:

-

Wooden pallets or crates

-

Anti-rust wrapping and moisture protection film

-

Clear labeling of heat numbers and dimensions

Global shipping options are available via air, sea, or express courier. Lead times vary depending on stock availability and cutting requirements.

Why Choose Us

-

Over 15 years of experience in nickel-based alloy production and supply

-

Wide stock range in Hastelloy X, C-22, C-276, Inconel 625, 718, and other high-performance alloys

-

Customized cutting and fabrication services to your exact specifications

-

Competitive pricing and reliable international delivery

-

Dedicated technical support from materials engineers

![]()

![]()

![]()

![]()

![]()