-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

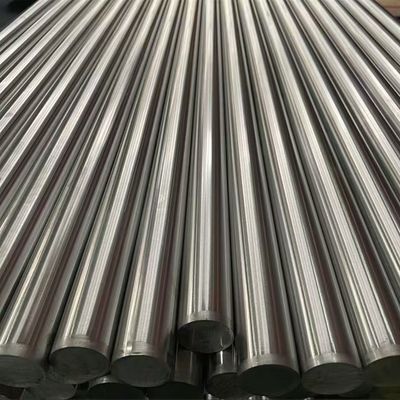

Incoloy 800H Solid Round Bar Corrosion-Resistent Alloy Stock com comprimentos e diâmetros personalizados

| Lugar de origem | CHINA |

|---|---|

| Marca | DELTA |

| Certificação | ISO |

| Número do modelo | INCOLOY 800H |

| Quantidade de ordem mínima | 10 kgs |

| Preço | 12-20 USD/Kg |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias com base na quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 3 toneladas por semana |

| Produtos | Incoloy 800H barra redonda | Nota | INCOLOY 800H |

|---|---|---|---|

| Diâmetro | 10 - 350mm | Comprimento | corte por encomenda de qualquer comprimento conforme pedido |

| Padrão | ASTM EN | Serviço | Corte |

| Porta de carregamento | Porto de Xangai | Superfície | preto, brilhante |

| Destacar | Incoloy 800H barra redonda,barras de liga de níquel resistentes à corrosão,comprimento personalizado Incoloy 800H stock |

||

Especificação de Produtos

|

Padrão

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grau

|

Série Monel: 400 K500

Série Inconel: 600 601 625 718 725 Série Incoloy: 800 800H 825 925 Série Hastelloy: B, B2, B3, C, C-276, C-4, C-22 Puro: Ni200, Ni201 |

||

|

Especificações

|

Barra redonda

|

Diâmetro: 4~300mm

|

|

|

Barra chata

|

Espessura

|

1.0~100mm

|

|

|

Largura

|

1~1500mm

|

||

|

Barra quadrada

|

Tamanho: 4*4-100*100mm

|

||

|

Comprimento

|

2m, 5.8m, 6m, ou conforme necessário.

|

||

|

Superfície

|

Preta, descascada, polida, brilhante, jateada, linha de cabelo, etc.

|

||

|

Prazo de Preço

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Tempo de Entrega

|

Tamanho padrão em estoque, entrega imediata ou conforme a quantidade do pedido.

|

||

Barra Redonda Sólida Incoloy 800H Estoque de Liga Resistente à Corrosão com Comprimentos e Diâmetros Personalizados

Para indústrias que operam em ambientes de calor extremo e corrosivos — desde o processamento petroquímico até a geração de energia nuclear — a confiabilidade do material impacta diretamente a segurança e a eficiência operacional. As barras redondas sólidas Incoloy 800H surgem como uma solução de primeira linha, combinando resistência excepcional a altas temperaturas, resistência robusta à corrosão e personalização versátil para atender às exigentes necessidades industriais. Como uma variante aprimorada da família Incoloy 800, esta liga de níquel-ferro-cromo é projetada para manter a integridade estrutural onde os metais padrão falham, tornando-a um elemento essencial em aplicações críticas em todo o mundo.

Composição Principal: A Base do Desempenho

As propriedades superiores do Incoloy 800H derivam de sua composição química precisamente balanceada, que prioriza a estabilidade em altas temperaturas e a resistência à corrosão. Ao contrário das ligas genéricas, sua matriz de níquel-cromo-ferro é otimizada com adições controladas de carbono, titânio e alumínio para evitar a sensibilização e aumentar a resistência à fluência.

|

Elemento |

Faixa de Composição (%) |

Função Principal |

|---|---|---|

|

Níquel (Ni) |

30.0 – 35.0 |

Aumenta a resistência à fissuração por corrosão sob tensão e a estabilidade da estrutura austenítica |

|

Cromo (Cr) |

19.0 – 23.0 |

Forma uma camada protetora de óxido para resistência à oxidação e carburização |

|

Ferro (Fe) |

≥ 39.5 |

Fornece resistência básica e custo-efetividade |

|

Carbono (C) |

0.05 – 0.10 |

Melhora a resistência à fluência e à ruptura em altas temperaturas |

|

Titânio (Ti) |

0.15 – 0.60 |

Estabiliza a estrutura e previne a corrosão intergranular |

|

Alumínio (Al) |

0.15 – 0.60 |

Aumenta a resistência à oxidação e forma precipitados coerentes |

|

Cobre (Cu) |

≤ 0.75 |

Limita as impurezas, mantendo a compatibilidade da liga |

Esta composição cria uma estrutura de rede cúbica de face centrada que retém a ductilidade e a resistência em flutuações extremas de temperatura, de temperatura ambiente a 1100°C.

Resistência Mecânica e à Corrosão: Projetada para Extremos

As barras redondas Incoloy 800H se destacam em ambientes onde a carga mecânica e o ataque químico são ameaças constantes. Suas propriedades mecânicas permanecem consistentes mesmo sob exposição prolongada ao calor intenso, diferenciando-as dos aços inoxidáveis convencionais.

Principais Propriedades Mecânicas (Condição Recozida)

|

Propriedade |

Especificação |

|---|---|

|

Resistência à Tração |

520 – 690 MPa |

|

Limite de Escoamento (0.2% Offset) |

210 – 400 MPa |

|

Alongamento |

≥ 30% |

|

Dureza (HRC) |

≤ 30 |

|

Densidade |

8.0 g/cm³ |

|

Ponto de Fusão |

1350 – 1400°C |

Além da resistência mecânica, é na resistência à corrosão que o Incoloy 800H realmente se destaca. Seu alto teor de cromo forma uma camada de óxido densa e aderente que resiste à oxidação, enquanto o níquel mitiga a fissuração por corrosão sob tensão em ambientes aquosos. Esta liga tem um desempenho excepcionalmente bom em:

-

Soluções de ácido nítrico e ácido orgânico

-

Misturas de vapor, ar e dióxido de carbono até 500°C

-

Atmosferas sulfidizantes e em fornos petroquímicos

-

Água em alta temperatura em geradores de vapor nucleares

Notavelmente, seu baixo teor de carbono e a relação Ti:C otimizada eliminam os riscos de sensibilização, garantindo resistência à corrosão intergranular mesmo após soldagem ou exposição ao calor.

Especificações do Produto: Personalizável para Cada Aplicação

A flexibilidade é fundamental para os componentes industriais, e nossas barras redondas Incoloy 800H são fornecidas com amplas opções de personalização para atender aos requisitos precisos do projeto. Todo o estoque está em conformidade com os padrões internacionais, incluindoASTM B408/ASME SB408, DIN, JIS e EN para garantir qualidade e compatibilidade.

|

Parâmetro |

Faixa Padrão |

Opções de Personalização |

|---|---|---|

|

Diâmetro |

4 mm – 500 mm |

Até 800 mm sob consulta |

|

Comprimento |

1 m – 6 m |

Comprimentos cortados sob medida (mínimo de 100 mm) |

|

Acabamento da Superfície |

Brilhante, polido, preto |

Retificação de precisão (Ra ≤ 0.8 μm) disponível |

|

Tolerância |

Estirado a frio: ±0.07 mm (≤18 mm diâmetro) |

Opções de tolerância apertada para aplicações críticas |

|

Forma |

Barra redonda sólida |

Variantes de barra quadrada, hexagonal e chata disponíveis |

Cada lote passa por testes rigorosos de qualidade, incluindo identificação positiva do material (PMI), verificação das propriedades mecânicas, testes de corrosão por pites e análise macro/microestrutural para garantir a conformidade com os padrões da indústria.

Aplicações Industriais: Onde a Confiabilidade é Mais Importante

As barras redondas Incoloy 800H são confiáveis em setores onde a falha do equipamento pode levar a consequências catastróficas. As principais aplicações incluem:

Processamento Petroquímico e Químico

-

Tubos de craqueamento e componentes de fornos para reforma de hidrocarbonetos

-

Tubos de trocadores de calor e internos de reatores

-

Estruturas de suporte de catalisadores em vasos de reação corrosivos

Geração de Energia

-

Tubos de geradores de vapor em usinas nucleares

-

Sistemas de exaustão de turbinas a gás e tubulações de alta temperatura

-

Componentes de caldeiras em usinas termelétricas a carvão

Tratamento Térmico e Fabricação

-

Cestas, bandejas e acessórios de fornos para recozimento em alta temperatura

-

Suportes de elementos de aquecimento elétrico

-

Componentes de equipamentos de processamento térmico

Sua capacidade de suportar altas temperaturas e meios corrosivos o torna insubstituível nesses setores, muitas vezes estendendo a vida útil do equipamento em 2 a 3 vezes em comparação com as ligas padrão.

Por que escolher nossas Barras Redondas Incoloy 800H?

Nosso compromisso com a qualidade e a centralização no cliente diferencia nosso estoque de ligas:

-

Rastreabilidade: Certificação completa do material com composição específica do lote e relatórios de teste

-

Personalização: Tempo de resposta rápido para diâmetros não padronizados e comprimentos cortados

-

Garantia de Qualidade: Teste PMI 100% para eliminar misturas de materiais

-

Conformidade Global: Atende aos padrões da indústria ASTM, ASME e internacionais

-

Suporte Técnico: Orientação especializada em soldagem, usinagem e tratamento térmico

Seja para um protótipo em pequena escala ou um grande projeto industrial, nossas barras redondas sólidas Incoloy 800H oferecem desempenho consistente nos ambientes mais severos do mundo. Entre em contato com nossa equipe hoje para discutir suas especificações e garantir uma solução de material confiável que se alinha às suas necessidades operacionais.

![]()

![]()

![]()

![]()