Todos os Produtos

-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

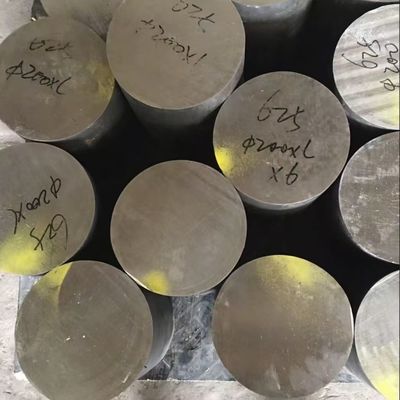

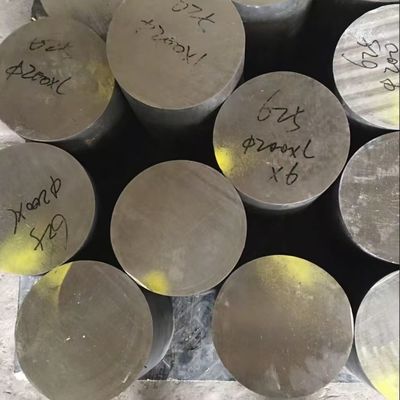

Inconel 625 Round Bar (ASTM B446), ¾-8" Diameter, Marine Engineering; matches Alloy 625

| Lugar de origem | CHINA |

|---|---|

| Marca | DELTA |

| Certificação | ISO |

| Número do modelo | Inconel 625 |

| Quantidade de ordem mínima | 10 kgs |

| Preço | 20 - 35 USD/Kg |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias com base na quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 3 toneladas por semana |

Detalhes do produto

| Produtos | Barra redonda de Inconel 625 | Nota | Inconel 625 |

|---|---|---|---|

| Diâmetro | 10 - 350mm | Comprimento | corte por encomenda de qualquer comprimento conforme pedido |

| Padrão | ASTM EN | Serviço | Corte |

| Porta de carregamento | Porto de Xangai | Superfície | preto, brilhante |

| Destacar | Inconel 625 round bar ASTM B446,Nickel alloy marine engineering bar,Alloy 625 round bar ¾-8 diameter |

||

Descrição de produto

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725 Incoloy series: 800 800H 825 925 Hastelloy series: B,B2,B3,C,C-276,C-4,C-22 Pure: Ni200, Ni201 |

||

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

|

Width

|

1~1500mm

|

||

|

Square bar

|

Size: 4*4-100*100mm

|

||

|

Length

|

2m, 5.8m, 6m, or as required.

|

||

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

||

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

||

Inconel 625 Round Bar (ASTM B446), ¾-8" Diameter, Marine Engineering; matches Alloy 625

Overview

Engineered to meet the uncompromising demands of marine and offshore environments, our Inconel 625 Round Bar adheres strictly to ASTM B446 standards and offers full compatibility with Alloy 625. Available in diameters ranging from ¾" to 8"—the most requested sizes for marine engineering—this nickel-chromium-molybdenum alloy delivers exceptional corrosion resistance, high-temperature stability, and structural strength without requiring post-fabrication heat treatment. Whether deployed in subsea risers, offshore platforms, or shipboard systems, it provides long-term reliability in the harshest saltwater and industrial environments.

Key Specifications & Compliance

- Standard: ASTM B446 / ASME SB446; UNS N06625 ( Werkstoff Nr. 2.4856 )

- Dimensions: Diameters ¾"–8", lengths up to 20' (custom lengths available); tolerances per ASTM A484/A484M

- Finish: Bright polished, black oxide, or mill finish (suitable for welding and machining)

- Compliance: NACE MR 0175/ISO 15156 (for sour service), RoHS, and REACH compliant

Chemical Composition (ASTM B446)

The alloy’s performance stems from its precisely balanced chemistry, which includes:

This composition ensures the round bar matches Alloy 625’s performance while exceeding basic marine material requirements .

Mechanical Properties

Our Inconel 625 Round Bar delivers consistent strength across temperature ranges, critical for dynamic marine applications:

- Density: 8.44 g/cm³ (0.305 lbs/in³)

- Tensile Strength: 930 MPa (135,000 psi) minimum

- Yield Strength (0.2% offset): 517 MPa (75,000 psi) minimum

- Elongation: 42.5% minimum (annealed condition)

- Temperature Resistance: Maintains strength up to 982°C (1,800°F)

Cold-worked variants (20–75% cold reduction) boost tensile strength to 2,144 MPa (311 ksi) for high-stress components like subsea clamps .

Why It’s Ideal for Marine Engineering

Marine environments subject materials to chloride corrosion, thermal cycling, and high pressure—challenges this round bar solves:

1. Unmatched Corrosion Resistance

The alloy’s chromium-molybdenum-niobium blend resists pitting, crevice corrosion, and stress corrosion cracking (SCC) in seawater, splash zones, and tidal areas . It outperforms standard steels in sour gas and acidic brine, extending equipment life by 3–5x .

2. Weldability & Fabrication

No post-weld heat treatment is needed, a critical advantage for on-site repairs of offshore platforms or ship hulls . Its low carbon content prevents sensitization in heat-affected zones (HAZs), ensuring weld joints retain corrosion resistance .

3. Versatile Marine Applications

Common uses include:

- Subsea: Flexible risers, manifold piping, Christmas tree (XMT) components

- Topside: Flare stacks, seawater lift pipes, high-pressure separators

- Shipbuilding: Valve trim, heat exchangers, propeller shafts

How It Matches Alloy 625

While minor elemental variations exist (e.g., slightly higher niobium in Inconel 625), our round bar achieves identical performance metrics:

- Same corrosion resistance in seawater and chemicals

- Equivalent high-temperature strength (up to 1,500°C/2,730°F)

- Interchangeable in all Alloy 625-specified designs

Quality Assurance

Each round bar undergoes:

- Chemical analysis via X-ray fluorescence (XRF)

- Mechanical testing (tensile, hardness)

- Ultrasonic inspection (UT) for internal defects

- Surface quality checks per ASTM B446

Certificates of Compliance (CoC) and mill test reports (MTRs) are provided with every order.

Ordering Information

We offer:

- Stock diameters: ¾", 1", 1.5", 2", 3", 4", 6", 8"

- Custom cuts (1'–20' lengths)

- Value-added services: Threading, grooving, heat treatment

- Fast lead times (2–5 days for stock; 2–3 weeks for custom)

![]()

![]()

![]()

![]()

Produtos recomendados