모든 제품

-

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

라이안 이오네스쿠매우 좋은 소재 품질. 우리는 10년 이상을 협력하게 합니다. 그들은 강철 소재의 다량 종류를 거래합니다. 좋은 모든 소재 품질. 그들 모든 소재 품질을 위한 의무. 우리는 활공하고 있고 계속되고 미래에 그들과 협력합니다

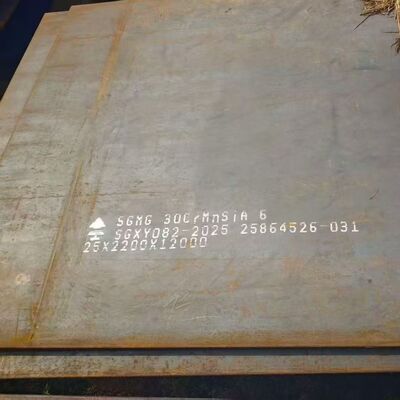

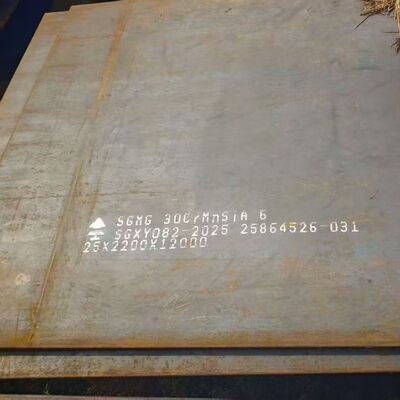

Precision-Rolled 30CrMnSiA Structural Steel Plate with Excellent Toughness and Wear Resistance

제품 상세 정보

| 제품 | 30CrMnSiA | 두께 | 10.0 - 200.0mm |

|---|---|---|---|

| 너비 | 1000-2200mm | 길이 | 2000-12000mm |

| 기준 | ASTM EN GB | 다른 자료 | 탄소강, 합금 강, 스테인레스 강 |

| 상표 | 바오스틸 시니유 XINGCHENG HBIS | 서비스 | 절단 |

제품 설명

Products Specification

| Product Name | 30CrMnSiA Alloy Steel Plate |

| Thickness | 10mm~200mm |

| Width | 1000~3000mm,common width is 1250mm,1500mm,2000mm,2200mm |

| Length | 1000~12000mm,can as your request cut |

| Surface | Clean,finished, blasting and painting or as your request |

| Delivery | Hot Rolled, Controlled Rolling,Normalizing,Annealing, Tempering,Quanching, Q+T |

| Packing | Steel Strapping,fixing in the Container,can customize |

| Thickness tolerance | ±0.3mm |

| Application | It is mainly used to make structural parts such as car girder, beam, transmission shaft and car chassis parts, which can reduce the weight of the parts. |

Precision-Rolled 30CrMnSiA Structural Steel Plate with Excellent Toughness and Wear Resistance

Engineered for Demanding Structural Applications

Precision-rolled 30CrMnSiA structural steel plate combines high tensile strength, superior impact toughness, and enhanced wear resistance—making it a preferred choice for heavy-duty mechanical components, defense systems, mining equipment, and critical infrastructure. Manufactured under stringent metallurgical controls and rolled to tight dimensional tolerances, this medium-carbon alloy steel delivers consistent performance across thicknesses from 10 mm to 200 mm, with optional precision finishing for reduced machining requirements.

Unlike standard hot-rolled plates, our precision-rolled 30CrMnSiA undergoes controlled cooling, surface conditioning, and optional straightening to achieve improved flatness, uniform microstructure, and minimized scale—ideal for applications where dimensional accuracy and material reliability are paramount.

Key Performance Advantages

| Feature | Benefit |

|---|---|

| High Strength-to-Weight Ratio | Enables lighter yet stronger structural designs |

| Excellent Low-Temperature Toughness | Maintains ductility down to –40°C; suitable for arctic or high-altitude use |

| Enhanced Wear & Abrasion Resistance | Chromium and manganese content improve surface durability |

| Good Hardenability | Achieves uniform hardness through thick cross-sections |

| Controlled Rolling Process | Reduces internal stresses and improves dimensional consistency |

| Custom Thickness Tolerances | ±0.3 mm achievable on select thicknesses (vs. standard ±1.0 mm) |

Note: While 30CrMnSiA offers strong mechanical properties in the as-rolled condition, optimal performance is achieved after quenching and tempering (Q&T). For welded structures, preheating (200–300°C) and post-weld heat treatment are strongly recommended.

Chemical Composition (GB/T 11251-2009 Standard)

| Element | Content (%) | Role in Performance |

|---|---|---|

| Carbon (C) | 0.28 – 0.34 | Provides core strength via martensitic transformation |

| Silicon (Si) | 0.90 – 1.20 | Enhances strength and deoxidizes molten steel |

| Manganese (Mn) | 0.80 – 1.10 | Increases hardenability and hot workability |

| Chromium (Cr) | 0.80 – 1.10 | Boosts wear resistance and deep-section hardening |

| Sulfur (S) | ≤ 0.025 | Minimized to prevent hot shortness |

| Phosphorus (P) | ≤ 0.025 | Controlled to avoid cold brittleness |

| Residual Elements (Ni, Cu, etc.) | ≤ 0.30 total | Kept low for weld integrity and purity |

The “A” designation signifies higher purity compared to standard 30CrMnSi—critical for fatigue- and impact-loaded parts.

Mechanical Properties (Typical – After Q&T)

表

| Property | Value | Standard |

|---|---|---|

| Tensile Strength (Rm) | 1080 – 1275 MPa | GB/T 228.1 |

| Yield Strength (Rp0.2) | ≥ 835 MPa | GB/T 228.1 |

| Elongation (A5) | ≥ 10% | GB/T 228.1 |

| Reduction of Area (Z) | ≥ 45% | GB/T 228.1 |

| Impact Energy (20°C) | ≥ 39 J | GB/T 229 |

| Impact Energy (–40°C) | ≥ 88 J (premium grade) | GB/T 229 |

| Hardness | 24–32 HRC (Q&T); ≤229 HB (as-rolled) | ISO 6508 / GB/T 231.1 |

Properties may vary slightly based on plate thickness and heat treatment parameters.

Precision Rolling Specifications

| Parameter | Standard Offering | Precision Option |

|---|---|---|

| Thickness Range | 10 – 200 mm | 10 – 100 mm (tight tolerance) |

| Thickness Tolerance | ±0.5 to ±2.0 mm (per GB/T 709) | ±0.3 mm (on request, 10–50 mm) |

| Flatness | ≤ 5 mm/m | ≤ 2 mm/m (with leveling) |

| Surface Finish | Hot-rolled black scale | Shot-blasted, pickled, or lightly ground |

| Edge Condition | Mill edge | Trimmed edges available |

| Internal Quality | Visual inspection | Ultrasonic Testing (UT) per ASTM A578 Grade B/C |

Common Industrial Applications

| Industry | Typical Components |

|---|---|

| Heavy Machinery | Excavator arms, crusher shafts, gear blanks |

| Defense & Armor | Vehicle chassis, weapon mounts, structural brackets |

| Oil & Gas | Drill collars, high-pressure flanges, valve bodies |

| Mining & Construction | Wear plates, bucket teeth supports, conveyor frames |

| Rail & Transportation | Axle boxes, coupler yokes, suspension links |

| Power Generation | Turbine housings, fasteners, high-stress brackets |

Thanks to its balanced combination of strength, toughness, and wear resistance, 30CrMnSiA outperforms many carbon steels in abrasive or high-impact environments.

Custom Processing & Value-Added Services

We go beyond raw plate supply to deliver ready-to-machine or near-net-shape components:

- Precision Cutting: Waterjet (up to 200 mm), plasma, or laser cutting per CAD/DXF

- Edge Machining: Beveling, chamfering, or radius edges for welding prep

- Surface Treatment: Shot blasting (Sa2.5), anti-rust oiling, or temporary painting

- Heat Treatment: In-house or certified partner Q&T cycles

- Certification: EN 10204 3.1 Mill Test Reports, UT certificates, chemical analysis

All materials are fully traceable by heat number and comply with international shipping standards.

Quality Assurance

- ✅ ISO 9001:2015 certified production

- ✅ Melt-by-melt chemical control via EAF + LF + VD refining

- ✅ Optional third-party inspection (SGS, Bureau Veritas, etc.)

- ✅ Full documentation for aerospace, defense, and pressure equipment projects

Why Choose Our Precision-Rolled 30CrMnSiA?

- Consistent Microstructure: Controlled rolling and cooling minimize banding

- Reduced Machining Costs: Tighter tolerances = less material removal

- Global Export Experience: FOB or DDP to North America, EU, Middle East, and APAC

- Technical Collaboration: Our engineers support material selection, processing, and failure analysis

Precision-rolled 30CrMnSiA steel plate, high-toughness alloy steel plate, wear-resistant 30CrMnSiA, structural steel plate 10-200mm, GB/T 11251 alloy steel, custom tolerance 30CrMnSiA plate, China 30CrMnSiA supplier, quenched and tempered structural steel, impact-resistant steel for heavy machinery, ultrasonically tested alloy plate.

추천된 제품