すべての製品

-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

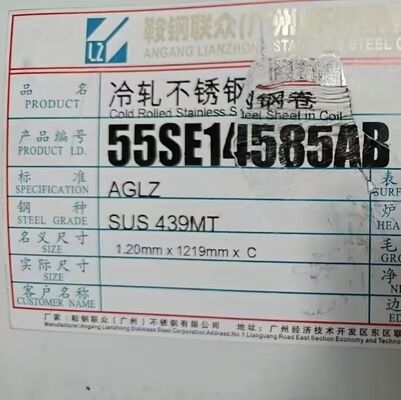

439 高温用フェリティックステンレス鋼板 4FT*8FT

商品の詳細

| 製品 | ステンレス鋼板 | 学年 | 439 |

|---|---|---|---|

| 厚さ | 0.5~10.0 | 技術 | コールドロール |

| 幅 | 1219mm | 表面 | 2B 2D NO.1 |

| 標準 | ASTM GB JIS EN DIN | MOQ | 1トン |

| ハイライト | 439 フェリット式不?? 鋼板,高温ステンレス鋼板,4x8フィートのフェリティック鋼板 |

||

製品の説明

439 高温用フェリティックステンレス鋼板 4FT*8FT

ステンレス鋼板の仕様

| 名前 | 439 ステンレス鋼板 |

| わたしたち の 成績 |

200シリーズ: 201 202 300シリーズ: 301 304,304L,304H,309S,310S314316L,316Ti,316H,316LN,317L321,329,347 400シリーズ:409L410410S415,416,420,430,431オーケストラ439,441,443,444,445,446 超ステンレス鋼 904L926254SMO,654SMO,15-5PH,17-4PH,17-7PHなど ニッケル合金:C276,C22,G35,合金X,モネル400,K500,インコネル600601,617,625,718"インコロイ800800HT"825... など |

| テクニック | ホットロール,コールドロール,鍛造 |

| スタンダード | JIS,AISI,ASTM,DIN,TUV,BV,SUSなど |

| 厚さ | 0. 1 80.0mm |

| 幅範囲 | 10mm 2000mm |

| 長さ | カスタマイズ |

| 終わって | 2B,2D,NO1バイアス 違う48K ブラシ 髪型 防水 砂吹き |

| サービス | レーザー 切断,曲げ |

| サンプル | 入手可能 |

439 高温用途用フェリティックステンレス鋼板 4FT × 8FT

製品概要

標準の4フィート×8フィート (1219 mm × 2438 mm) の格付けの439級フェリティックステンレス鋼板は,高温環境の要求のために特別に設計されています.自動車の排気装置を含む工業用熱交換機,バーナー部品,煙道.チタン安定化フェリティックステンレス鋼として,グレード439は,酸化,熱疲労,粒間腐食により,信頼性の高い304や321のような高価なオーステニティックグレードのコスト効率の良い代替品です

0.8mmから10.0mmの厚さで利用可能で,4FT × 8FTのシートサイズは,標準化,処理が簡単で廃棄物が少ないパネル.

なぜ4FT × 8FT グレード 439シートを選ぶのか?

4'×8'フォーマットは,北米で業界が好むシートサイズであり,以下のような理由で世界中で広く採用されています.

- 標準のCNC切削,レーザー,プラズマテーブルとの互換性

- スタンプとブランキング作業のための効率的な巣

- 中量生産のコイル加工に比べ,取り扱いが減る

- 倉庫と物流の簡素化

このシートサイズは,グレード439の固有の高温性能と組み合わせると,プロトタイプ,バッチ製造,交換部品製造に理想的になります.

高温 で 使用 する の の 主要 な 利点

✅ 800°C (1472°F) まで 酸化 耐性

グレード439は,高温の排気ガスや燃焼環境への長期的曝露により,スケーリングや劣化に抵抗する安定したクロム豊富な酸化層を形成する.

グレード439は,高温の排気ガスや燃焼環境への長期的曝露により,スケーリングや劣化に抵抗する安定したクロム豊富な酸化層を形成する.

✅ タイタン 安定化

Ti は炭素と窒素を結合し,溶接またはサービス中に500~800°Cでクロムカービッドの降水を防止し,敏感化をなくし,長期間の耐腐蝕性を確保します.

Ti は炭素と窒素を結合し,溶接またはサービス中に500~800°Cでクロムカービッドの降水を防止し,敏感化をなくし,長期間の耐腐蝕性を確保します.

✅ 低熱膨張

フェリティス構造は,熱循環中に歪みや関節ストレスを軽減し,オウステニトスチールよりも30%低い熱膨張係数を提供します.

フェリティス構造は,熱循環中に歪みや関節ストレスを軽減し,オウステニトスチールよりも30%低い熱膨張係数を提供します.

✅ 熱伝導性が良さ

マニホールドやヒートシールドの熱散を向上させ,システムの効率と部品の寿命を向上させる.

マニホールドやヒートシールドの熱散を向上させ,システムの効率と部品の寿命を向上させる.

✅ 優れた製造能力

高温耐久性にもかかわらず,グレード439は,複雑な排気ジオメトリを曲げ,ローリング,深く描くのに適した良好な冷凍形成特性を保持しています.

高温耐久性にもかかわらず,グレード439は,複雑な排気ジオメトリを曲げ,ローリング,深く描くのに適した良好な冷凍形成特性を保持しています.

テクニカル仕様

| プロパティ | 詳細 |

|---|---|

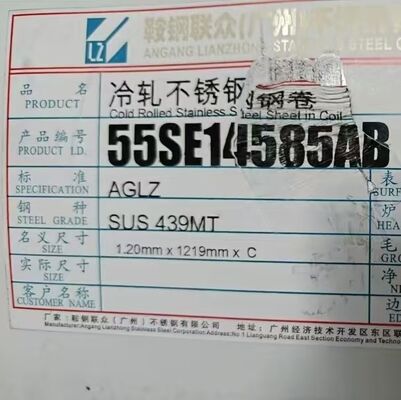

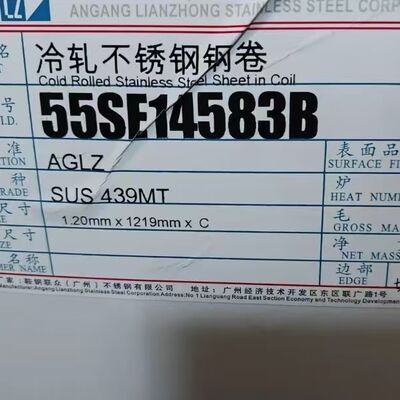

| グラード | UNS S43035 / ASTM A240タイプ 439 / EN 1.4510 / JIS SUS 439 |

| サイズ | 4 フィート × 8 フィート (1219 mm × 2438 mm) 標準;カスタムサイズ |

| 厚さ範囲 | 0.8mm 10.0mm (自動車用標準計:1.2mm,1.5mm,2.0mm) |

| 表面塗装 | 2B (スタンダード),BA (Bright Annealed),No.1ヘアライン |

| 配達条件 | 焼き 漬け |

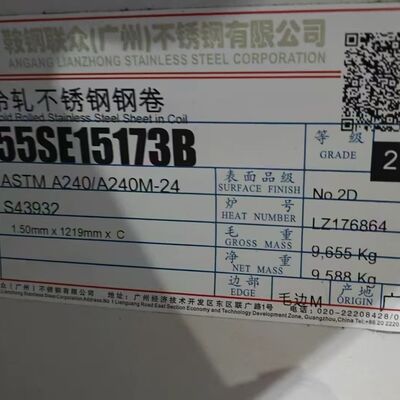

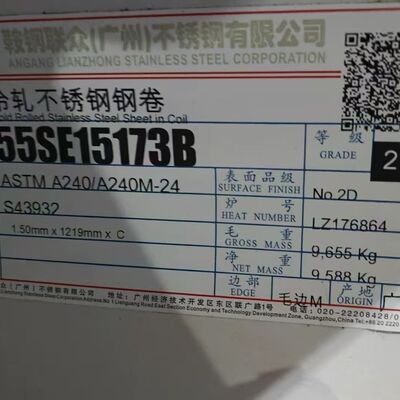

| 基準 | ASTM A240/A240M,EN 10088-2,JIS G4305 |

| 認定 | ISO 9001,IATF 16949,RoHS準拠;ミール試験報告 (MTR) が含まれています |

化学成分 (典型,重量%)

| エレメント | C について | そうだ | ミニ | P | S | C.C. | ニ | N について | ティ |

|---|---|---|---|---|---|---|---|---|---|

| マックス/レンジ | ≤0.03 | ≤10 | ≤10 | ≤0.04 | ≤0.03 | 17.0 ¥190 | ≤0.5 | ≤0.04 | ≥0.2 + 4×(C+N); ≤1.10 |

注: 精密なTi制御により,粒子が過剰に粗くなることなく最適な安定が保証されます.

メカニカル・物理特性 (アニール)

| プロパティ | 価値 |

|---|---|

| 張力強度 | 450~600 MPa |

| 収益力 (0.2%オフセット) | ≥280 MPa |

| 伸縮 | ≥25% (50mm) |

| 硬さ (HRB) | ≤88 |

| 密度 | 7.70g/cm3 |

| 熱伝導性 (100°C) | ¥26 W/m·K |

| 熱膨張係数 (20~100°C) | 10.4 × 10−6 /°C |

| 最大連続使用温度 | 800°C (1472°F) |

高温での一般的な用途

- 熱ショックや酸化に耐える

- カタリティックコンバーターハウジング 周期的な加熱下で整合性を維持する

- マフラー&レゾナタ 内部酸性凝縮と外部の道路塩との闘い

- 産業用バーナーチューブ&フュース 燃焼副産物に耐える

- 熱シールドと排気栓 放射熱を反射し散布する

- 農家・建設機器の排気ガス 厳しい作業条件で耐久性

比較: グレード 439 と 代替品

| 特徴 | 439 | 409 | 430 | 304 |

|---|---|---|---|---|

| 最大使用温度 (°C) | 800 | 650 | 700 | 870 |

| 安定した? | そう (Ti) | そう (Ti) | 違う | 番号 (321を除く) |

| 溶接可能性 (溶接状態) | すごい | 良かった | 貧しい | すごい |

| 耐腐食性 | とても良い | 適度 | 良かった | すごい |

| 費用 | 低~中等 | 低い | 低い | ハイ |

| 熱膨張 | 低い | 低い | 低い | ハイ |

グレード 439 は,300 シリーズ合金によるプレミアムコストなしで> 650 °C の性能を必要とするアプリケーションに最適なバランスを提供します.

品質保証

各4FT × 8FTシートには,

- AOD精製により超低インタースティシャル含有量まで生産

- 超音波検査 (重要な用途ではオプション)

- 表面の欠陥 (擦り傷,穴,ロールマーク) の検査

- 全 EN 10204 3.1 ミルン試験報告

- 溶融から輸送まで追跡可能

私たちの施設は IATF 16949 認証を取得し 自動車品質管理システムの遵守を保証しています

梱包と取り扱い

- 防傷紙で分離されたシート

- 木製の輸出パレットに鋼筋のストラッパーで包装されている

- コーナーガードで保護されたエッジ

- 海上貨物用防水包装

- グレード,熱数,寸法,基準でマーク

持続可能性 の 益

- 劣化なしで100%リサイクル可能

- 軽量化設計が可能 (細いゲージでシステム重量が減る)

- 寿命が長い = 交換が少ない = 環境への影響が少ない

- OEMの持続可能性と循環経済目標を支持する

439 フェリティックステンレス鋼板 4x8, 4ft x 8ft 439 ステンレスプレート,高温ステンレス鋼板,グレード 439 1219x2438 mm,排気用チタン安定化ステンレス,ASTM 439 4x8 板,酸化耐性のある不oxidable steel,自動車排気ガスステンレスシート,EN 1.4510 4x8プレート,IATF 16949認定 439サプライヤー.

推薦されたプロダクト