-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

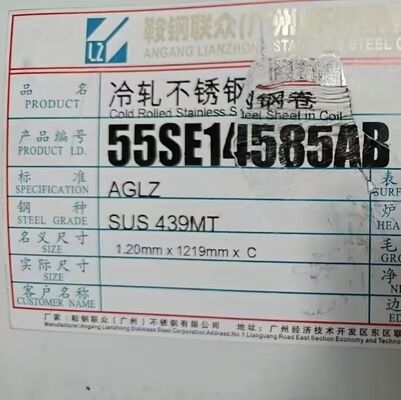

Φύλλο από φερριτικό ανοξείδωτο χάλυβα 439 4FT*8FT για εφαρμογές υψηλής θερμοκρασίας

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | TISCO |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | 439 |

| Ποσότητα παραγγελίας min | 500 κιλά |

| Τιμή | 1.5 - 2USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 20ton την εβδομάδα |

| προϊόντα | Φύλλο από ανοξείδωτο χάλυβα | Βαθμός | 439 |

|---|---|---|---|

| Πάχος | 0,5 - 10,0 | Τεχνολογικά | Ψυχρό έλασης |

| Πλάτος | 1219mm | Επιφάνεια | 2Β 2Δ ΑΡ.1 |

| Πρότυπο | ASTM ΜΒ JIS EN DIN | MOQ | 1 τόνος |

| Επισημαίνω | 439 φύλλα από ανοξείδωτο χάλυβα,φύλλα από ανοξείδωτο χάλυβα υψηλής θερμοκρασίας,4x8ft φερριτικό χαλύβδινο φύλλο |

||

Φύλλο από φερριτικό ανοξείδωτο χάλυβα 439 4FT*8FT για εφαρμογές υψηλής θερμοκρασίας

Προδιαγραφές Πλάκας Ανοξείδωτου Χάλυβα

| Όνομα | Πλάκα ανοξείδωτου χάλυβα 439 |

| Ο Βαθμός μας |

Σειρά 200: 201 202 Σειρά 300: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 Σειρά 400: 409L,410,410S,415,416,420,430,431,436L.439,441,443,444,445,446 Εξαιρετικός Ανοξείδωτος Χάλυβας: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Κράμα Νικελίου: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Τεχνική | Θερμής έλασης, Ψυχρής έλασης, Σφυρηλάτησης |

| Πρότυπο | JIS, AISI, ASTM, DIN, TUV, BV, SUS, κ.λπ. |

| Πάχος | 0.1 – 80.0mm |

| Εύρος πλάτους | 10mm – 2000mm |

| Μήκος | Προσαρμοσμένο |

| Φινίρισμα | 2B,2D,NO.1, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Υπηρεσία | Κοπή με λέιζερ, Κάμψη |

| Δείγμα | Διαθέσιμο |

Επισκόπηση προϊόντος

Γιατί να επιλέξετε φύλλα 4FT × 8FT βαθμού 439;

- Συμβατότητας με τυπικά τραπέζια κοπής CNC, λέιζερ και πλάσματος

- Αποτελεσματικής φωλεοποίησης για εργασίες σφράγισης και κοπής

- Μειωμένου χειρισμού σε σχέση με την επεξεργασία πηνίων για παραγωγή μεσαίου όγκου

- Απλοποιημένη αποθήκευση και εφοδιαστική

Βασικά πλεονεκτήματα για χρήση σε υψηλή θερμοκρασία

Ο βαθμός 439 σχηματίζει ένα σταθερό στρώμα οξειδίου πλούσιο σε χρώμιο που αντιστέκεται στην απολέπιση και την υποβάθμιση κατά τη διάρκεια παρατεταμένης έκθεσης σε θερμά καυσαέρια ή ατμόσφαιρες καύσης.

Το Ti συνδέει άνθρακα και άζωτο, αποτρέποντας την κατακρήμνιση καρβιδίου χρωμίου κατά τη διάρκεια της συγκόλλησης ή της υπηρεσίας στους 500–800°C—εξαλείφοντας την ευαισθητοποίηση και εξασφαλίζοντας μακροχρόνια αντοχή στη διάβρωση.

Η φερριτική δομή παρέχει ~30% χαμηλότερο συντελεστή θερμικής διαστολής από τους ωστενιτικούς χάλυβες, μειώνοντας την παραμόρφωση και την καταπόνηση των αρθρώσεων κατά τη διάρκεια της θερμικής κυκλοφορίας.

Ενισχύει την απαγωγή θερμότητας σε πολλαπλές εισαγωγής και θερμικές ασπίδες, βελτιώνοντας την απόδοση του συστήματος και τη διάρκεια ζωής των εξαρτημάτων.

Παρά την αντοχή του σε υψηλή θερμοκρασία, ο βαθμός 439 διατηρεί καλά χαρακτηριστικά ψυχρής διαμόρφωσης—κατάλληλο για κάμψη, κύλιση και βαθιά έλξη σύνθετων γεωμετριών εξάτμισης.

Τεχνικές προδιαγραφές

| Ιδιότητα | Λεπτομέρειες |

|---|---|

| Βαθμός | UNS S43035 / ASTM A240 Type 439 / EN 1.4510 / JIS SUS 439 |

| Διαστάσεις | 4 ft × 8 ft (1219 mm × 2438 mm) – standard; custom sizes available |

| Εύρος πάχους | 0.8 mm – 10.0 mm (common automotive gauges: 1.2 mm, 1.5 mm, 2.0 mm) |

| Φινίρισμα επιφάνειας | 2B (standard), BA (Bright Annealed), No.1, or Hairline |

| Κατάσταση παράδοσης | Ανοπτημένο και μαριναρισμένο |

| Πρότυπα | ASTM A240/A240M, EN 10088-2, JIS G4305 |

| Πιστοποιήσεις | ISO 9001, IATF 16949, RoHS compliant; Mill Test Reports (MTRs) included |

Χημική σύνθεση (Τυπική, wt%)

| Στοιχείο | C | Si | Mn | P | S | Cr | Ni | N | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Max/Range | ≤0.03 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 17.0–19.0 | ≤0.5 | ≤0.04 | ≥0.2 + 4×(C+N); ≤1.10 |

Μηχανικές & Φυσικές ιδιότητες (Ανοπτημένο)

| Ιδιότητα | Τιμή |

|---|---|

| Αντοχή σε εφελκυσμό | 450–600 MPa |

| Όριο διαρροής (0,2% offset) | ≥280 MPa |

| Επιμήκυνση | ≥25% (in 50 mm) |

| Σκληρότητα (HRB) | ≤88 |

| Πυκνότητα | 7.70 g/cm³ |

| Θερμική αγωγιμότητα (100°C) | ~26 W/m·K |

| Συντελεστής θερμικής διαστολής (20–100°C) | 10.4 × 10⁻⁶ /°C |

| Μέγιστη συνεχής θερμοκρασία λειτουργίας | 800°C (1472°F) |

Κοινές εφαρμογές υψηλής θερμοκρασίας

- Πολλαπλές εισαγωγής εξάτμισης αυτοκινήτων – Αντιστέκεται σε θερμικό σοκ και οξείδωση

- Περιβλήματα καταλυτικών μετατροπέων – Διατηρεί την ακεραιότητα υπό κυκλική θέρμανση

- Σιγαστήρες & Συντονιστές – Καταπολεμά την εσωτερική συμπύκνωση οξέος και το εξωτερικό αλάτι δρόμου

- Βιομηχανικοί σωλήνες καυστήρων & καπνοδόχοι – Αντέχει σε υποπροϊόντα καύσης

- Θερμικές ασπίδες & περιτυλίγματα εξάτμισης – Αντανακλά και διαχέει τη θερμότητα ακτινοβολίας

- Εξατμίσεις γεωργικού και κατασκευαστικού εξοπλισμού – Ανθεκτικό σε σκληρές συνθήκες λειτουργίας

Σύγκριση: Βαθμός 439 vs. Εναλλακτικές λύσεις

| Χαρακτηριστικό | 439 | 409 | 430 | 304 |

|---|---|---|---|---|

| Μέγιστη θερμοκρασία χρήσης (°C) | 800 | 650 | 700 | 870 |

| Σταθεροποιημένο; | Ναι (Ti) | Ναι (Ti) | Όχι | Όχι (εκτός εάν 321) |

| Συγκολλησιμότητα (ως συγκολλημένο) | Εξαιρετική | Καλή | Φτωχή | Εξαιρετική |

| Αντοχή στη διάβρωση | Πολύ καλή | Μέτρια | Καλή | Εξαιρετική |

| Κόστος | Χαμηλό–Μεσαίο | Χαμηλή | Χαμηλή | Υψηλή |

| Θερμική διαστολή | Χαμηλή | Χαμηλή | Χαμηλή | Υψηλή |

Διασφάλιση ποιότητας

- Παράγεται μέσω εξευγενισμού AOD για εξαιρετικά χαμηλή περιεκτικότητα σε διάμεσες ουσίες

- Υπερηχητικός έλεγχος (προαιρετικός για κρίσιμες χρήσεις)

- Επιθεωρείται για ελαττώματα επιφάνειας (γρατσουνιές, λακκούβες, σημάδια ρολού)

- Παρέχεται με πλήρη Έκθεση Δοκιμής Μύλου EN 10204 3.1

- Ανιχνεύσιμο από τήξη έως αποστολή

Συσκευασία & Χειρισμός

- Φύλλα διαχωρισμένα με αντισκωριακό χαρτί

- Δεσμίδες με χαλύβδινη ταινία σε ξύλινες παλέτες εξαγωγής

- Άκρες προστατευμένες με προστατευτικά γωνιών

- Αδιάβροχη περιτύλιξη για θαλάσσιες μεταφορές

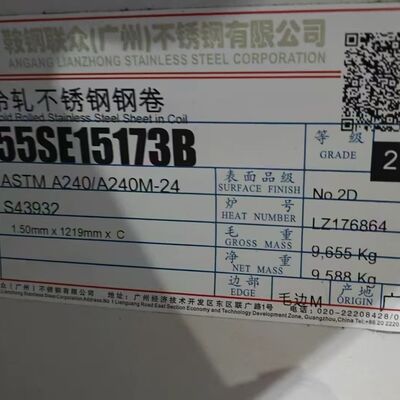

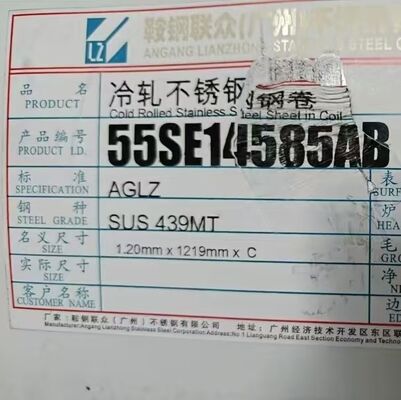

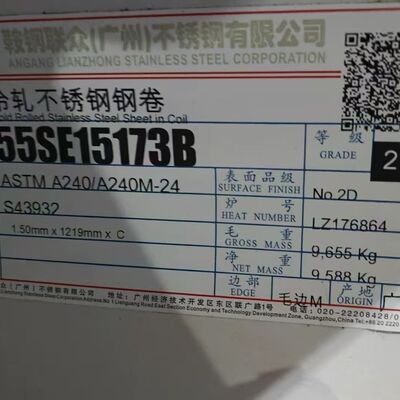

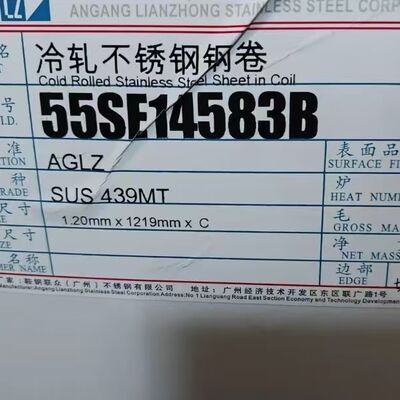

- Σημειωμένα με βαθμό, αριθμό θερμότητας, διαστάσεις και πρότυπα

Οφέλη βιωσιμότητας

- 100% ανακυκλώσιμο χωρίς υποβάθμιση

- Επιτρέπει ελαφρύ σχεδιασμό (λεπτά πάχη μειώνουν το βάρος του συστήματος)

- Μεγάλη διάρκεια ζωής = λιγότερες αντικαταστάσεις = μικρότερος περιβαλλοντικός αντίκτυπος

- Υποστηρίζει τους στόχους βιωσιμότητας και κυκλικής οικονομίας των OEM