すべての製品

-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

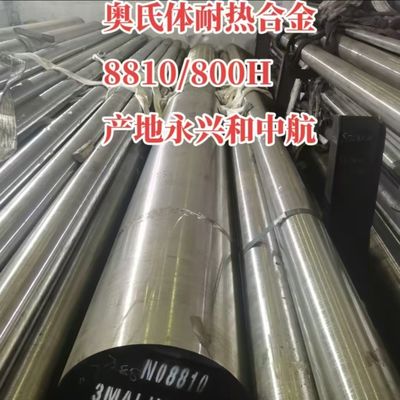

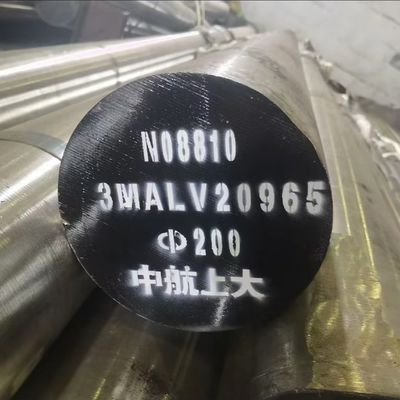

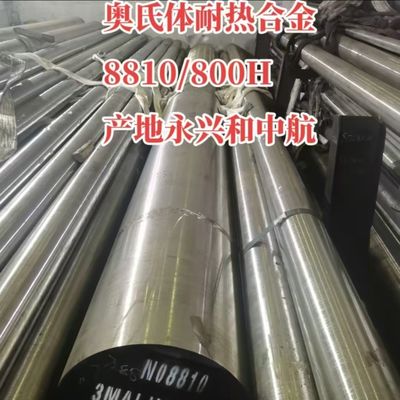

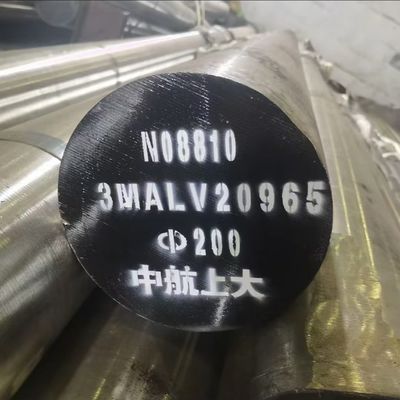

ホットロール&コールドドラッグインコロイ 800H丸棒 UNS N08810 ニッケル合金 明るい棒

商品の詳細

| 製品 | インコロイ 800H 丸い棒 | 学年 | INCOLOY 800H |

|---|---|---|---|

| 直径 | 10 - 350mm | 長さ | 要求に応じて任意の長さで切断 |

| 標準 | ASTM EN | サービス | 切断 |

| ロードポート | 上海港 | 表面 | ブラック、ブライト |

| ハイライト | インコロイ800H ニッケル合金棒,熱間圧延インコロイ800H 光輝棒,冷間引抜き UNS N08810 丸棒 |

||

製品の説明

製品仕様

|

スタンダード

|

AISI,ASTM,BS,DIN,GB,JIS

|

||

|

グレード

|

モネルシリーズ: 400 K500

インコネルシリーズ: 600 601 625 718 725 インコロイシリーズ: 800 800H 825 925 ハステロイシリーズ:B,B2,B3,C,C-276,C-4,C-22 純粋:Ni200,Ni201 |

||

|

仕様

|

丸いバー

|

直径:4~300mm

|

|

|

平面バー

|

厚さ

|

1.0~100mm

|

|

|

幅

|

1~1500mm

|

||

|

スクウェアバー

|

サイズ: 4*4-100*100mm

|

||

|

長さ

|

2m,5.8m,6m,または必要に応じて

|

||

|

表面

|

黒い,剥がれ,磨き,明るい,砂の爆発,髪のライン,など

|

||

|

価格 期間

|

EX-WORK FOB CFR CIF など

|

||

|

配達時間

|

スタンダードサイズは ストックで 迅速な配送または注文量です

|

||

ホットロール&コールドドラッグインコロイ 800H丸棒 UNS N08810 ニッケル合金 明るい棒

UNS N08810,一般的にIncoloy 800Hとして指定され,高温および腐食性のある環境での例外的な性能のために設計された高級ニッケル鉄クロム合金丸棒です.ホットロールとコールドロール (ライトバー) で入手可能この合金には,堅牢な機械的強度,優れた耐腐蝕性,構造的安定性があるため,極端な条件下で信頼性を要求する産業の礎材料となっています..化学処理機器や発電部品のいずれにせよ,UNS N08810の丸い棒は厳格な材料基準によって支持された一貫した性能を提供します.

UNS N08810 (インコロイ800H) 合金の主な特性

UNS N08810 の例外的な性能は,精密にバランスのとれた化学組成とアウステニティス型面中心立方格子構造に由来する.その炭素含有量は制御されている (0.05-0.10%) と最適化されたアルミニウム・チタン比 (0.85-1.20%組み合わせ) は,標準800シリーズ合金と区別して,上昇した温度でのスリップ耐性および構造安定性を向上させる.下記には,主要な特性の詳細な分解があります.:

1化学成分 (重量 %)

| エレメント | 最低値 | 最大 | 役割 |

|---|---|---|---|

| ニッケル (Ni) | 30.0 | 35.0 | 水質環境でのストレス腐食耐性強化 |

| クロム (Cr) | 19.0 | 23.0 | 酸化,炭化物化,およびピッティング腐食耐性を提供 |

| 鉄 (Fe) | バランス | バランス | 構造の整合性を保証する不純金属 |

| 炭素 (C) | 0.05 | 0.10 | 高温のクレイプと破裂強度を向上させる |

| マンガン (Mn) | - | 1.50 | 熱加工の補助 |

| シリコン (Si) | - | 1.00 | 腐食防止のための酸化膜形成をサポートする |

| 銅 (Cu) | - | 0.75 | 厳しい化学物質における互換性の問題を避けるために最小限に抑える |

| 硫黄 (S) | - | 0.015 | 壊れやすくならないように 縮小した |

| アルミ (Al) | 0.15 | 0.60 | 酸化抵抗を提昇する |

| チタン (Ti) | 0.15 | 0.60 | オーステニト構造を安定させ,敏感化を防止する |

2物理的・機械的性能

| 資産 | 仕様 | 注記 |

|---|---|---|

| 密度 | 8.0 g/cm3 | ホットロールとコールドロールで一致する |

| 溶融点 | 1350〜1400°C | 高温加工およびサービスに適している |

| 張力強度 (Rm) | 450 N/mm2 (分) | 600°C以上に長期的に曝された後でも維持される |

| 収力強度 (Rp0.2) | 180 N/mm2 (分) | 負荷下で構造の安定性を確保する |

| 伸縮 (A5%) | 35% (分) | 複雑なコンポーネントの形容性を可能にします |

| 酸化抵抗性 | 1000°Cまで | クロムオキシドの保護層を形成する |

ホットロール vs. コールドロール UNS N08810 丸い棒

UNS N08810 丸い棒は2つの主要プロセス―熱巻きと冷引―によって製造され,それぞれが特定の用途に合わせた特性を有する.下の表は,それらの主要な属性を比較しています.:

| 特徴 | ホットロール UNS N08810 丸いバー | 冷たく抽出した (明るい棒) UNS N08810 |

|---|---|---|

| 表面塗装 | 黒色,皮が剥がれたり,漬けになったり,マット質感 | 明るい,光滑で鏡のような (Ra ≤ 0.8μm) |

| 直径範囲 | 10~200mm (標準) 要求により大きいサイズ | 3~100mm;精密なアプリケーションのためのより狭い許容量 |

| 次元容量 | ±0.5mm | ±0.1mm |

| メカニカルプロパティ | 適度な硬さ;優れた柔らかさ | 高硬さ (150-180 HB); 拉伸強度向上 |

| 主要 な 利点 | 費用 効率 上 で,重量 機械 作業 に 適し | 直接組み立てに備え,後処理を減らす |

| 典型的な用途 | オーブンの部品,構造的支え | 精密シャフト,バルブ・スティン,計器部品 |

加工・製造能力

UNS N08810 丸い棒は,特殊な加工性を提供し,産業の様々な製造ニーズに対応します.

- ホットワーキング: 871-1232°C (1600-2250°F) で鍛造,曲げ,形付け,機械的性質を維持するために空気冷却によって処理可能.

- 冷凍加工:冷凍塗装は表面の仕上げと寸法精度を向上させ,冷凍加工の際には15分間982°Cで焼却することで柔らかさを回復します.

- 溶接: 標準的な不oxidable steel 溶接技術 (TIG,MIG,SMAW) に対応し,前熱なしで溶接;重度の耐腐蝕アプリケーションでは溶接後の焼却がオプションです.

- 機械加工: カービッドツールで機械加工可能; 硬化防止のために冷却液の使用が推奨されます.

産業用アプリケーションと使用事例

高温強度と耐腐蝕性のユニークな組み合わせは,要求の高い分野において UNS N08810 の丸い棒を不可欠なものとします.

- 化学・石油化学:硫黄を含む大気設備,窒素酸凝縮機,および酸化媒質と還元媒質の両方に耐性を高める裂化管.

- 発電:熱交換器管,蒸気発電機部品,ガスタービン部品は 600~700°Cの動作温度で,スクリープ変形がない.

- 原子力産業: コンデンサーシステムと原子炉補助パイプリング 金属学的な安定性と放射線抵抗性について評価

- 製造:高温環境における酸化や炭化物抵抗性のある炉具,炭化装置,加熱要素の包帯.

品質保証と基準の遵守

私たちのUNS N08810丸い棒は,ASTM B408 (ニッケル合金棒) とASME SB408を含む世界的な業界基準に準拠し,構成と性能の一貫性を保証します.各バッチは厳格な検査を受けます:

- 化学分析用X線発光 (XRF)

- メカニカルテスト (張力,出力,長さ)

- 非破壊性試験 (内部欠陥の超音波)

- 精密アレンジングで寸法検査

なぜ UNS N08810 を代替品よりも選ぶのか?

UNS N08811 (Incoloy 800HT) のような類似の合金と比較して,UNS N08810は700°C以下のアプリケーションで費用対効果の高い性能バランスを提供します.UNS N08810は,ほとんどの産業用耐熱用品に優れた価値を提供します.硫黄を含む大気への耐性も 化学処理における 304 不oxidable steelよりも優れている.

ホットロールバーのコスト効率性や 冷凍ロールバーの精度がUNS N08810 (インコロイ800H) 丸い棒は,世界で最も困難な環境でも信頼性の高い性能を提供します.オーダーメイドサイズ,技術データシート,またはアプリケーション特有の推奨事項については,私たちと連絡してください.

![]()

![]()

![]()

![]()

推薦されたプロダクト