すべての製品

-

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

Raian Ionescuよい物質的な質非常に。私達は協力することを持っている10年以上。それらはロットの種類の鋼鉄材料を交換する。よいすべての物質的な質。それらすべての物質的な質のための義務。私達はそれらに将来協力し続けるために平になっている

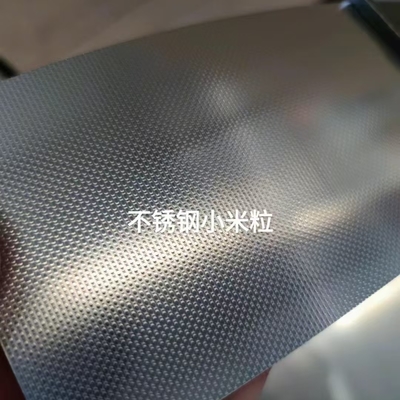

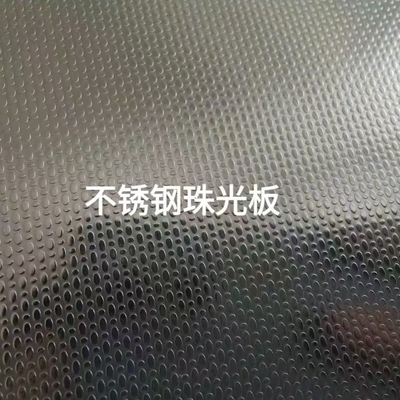

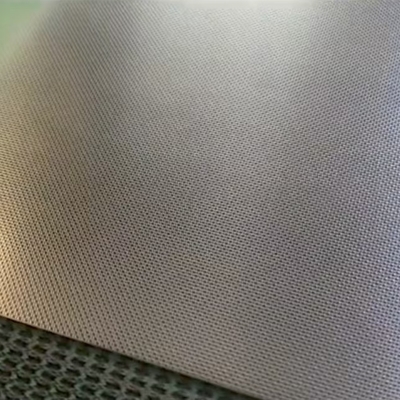

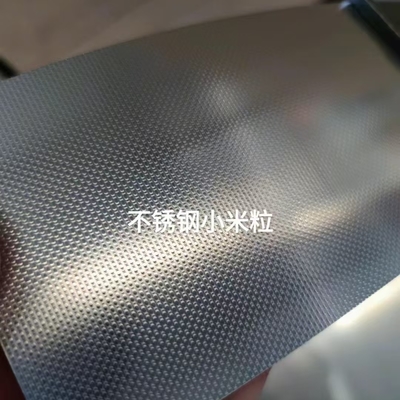

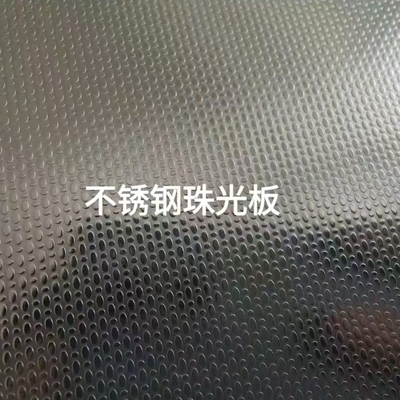

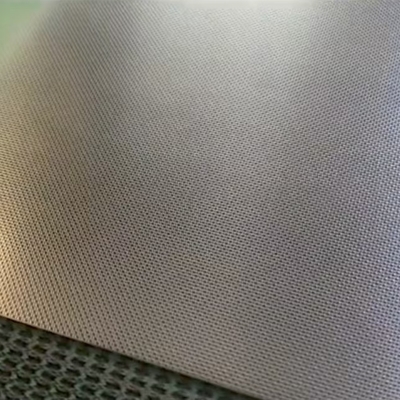

304 316L ステンレス・スティール 凸版 0.6-2.0mm 明るいビーズ・パターン

商品の詳細

| 製品 | 浮彫りにされたステンレス鋼 シート | 学年 | 304 201 316L 430 410Sなど |

|---|---|---|---|

| 標準 | ASTM EN JIS GB | サイズ | 1000*2000mm 1219*2438mm 1500*3000mm |

| 厚さ | 0.3〜1.5mm | タイプ | 冷間圧延 |

| 表面 | 彫刻されたパターン | 応用 | 装飾 |

| 梱包 | 木製のパレット | ||

| ハイライト | ステンレスエンボスシート,明るい珠紋鋼板,0.6-2.0mm ステンレス鋼板 |

||

製品の説明

ステンレス鋼エンボスシート 厚さ0.6~2.0mm 明るいビードパターンシート

製品仕様

| 製品名 | エンボスステンレス鋼シート |

| 長さ | 2000mm/2438mm/3000mm/または必要に応じて |

| 幅 | 1000mm/1219mm/1500mm/または必要に応じて |

| 厚さ | 0.4~2.0mm または必要に応じて |

| 規格 | AISI、JIS、GBなど |

| 表面仕上げ | 2Bエンボス、BA/研磨エンボス、HL/No.4エンボス、ミラーエンボスなど |

| エンボスパターン | ビーズ、菱形、水滴、米粒、さざ波、またはリクエストに応じた特殊パターン |

| 厚さ公差 | ±0.01~0.02mm/または必要に応じて |

| 材質 | 304/316/430/など |

| 用途 | エレベーター内装/建築/クラッディング/内装装飾 |

| MOQ | エンボス加工の在庫状況によります。在庫がない場合は、少なくとも1トン必要です。 |

| リードタイム | デポジット受領後10~30営業日以内 |

| 梱包 | 標準的な輸出用耐航性木製パッケージ/または必要に応じて |

| 生産能力 | 15,000 PCS/月 |

1. はじめに

明るいビードパターン(厚さ0.6mm~2.0mm)のステンレス鋼エンボスシートは、美的魅力、機能的な耐久性、滑り止め特性を兼ね備えたプレミアム金属製品です。「明るいビード」パターンは、独特のテクスチャード加工された表面を作り出す均一な隆起した円形モチーフを特徴とし、視覚的な興味と実用的な性能の両方を高めます。高品質のステンレス鋼合金から製造されたこれらのシートは、優れた耐食性、防錆性、耐摩耗性を発揮し、建築、工業、装飾分野での多様な用途に最適です。エンボス加工プロセスは、ユニークな装飾要素を追加するだけでなく、強度や表面硬度などの機械的特性も向上させます。

2. 一般的なグレード

304グレード

最も広く使用されているオーステナイト系ステンレス鋼である304は、耐食性、成形性、強度をバランスよく備えています。一般的な大気腐食、軽度の化学環境に耐え、適度な耐食性が求められる屋内および屋外用途に適しています。

316グレード

「マリングレード」ステンレス鋼として知られる316は、モリブデンを含み、塩化物誘起腐食(例:塩水、過酷な化学物質)に対する優れた耐性を提供します。沿岸プロジェクト、海洋機器、高湿度または化学物質への暴露がある工業環境に最適です。

201グレード

コスト効率の高いオーステナイト系合金である201は、304/316よりもニッケル含有量が少ないですが、優れた機械的強度と成形性を提供します。非クリティカルな装飾用途や、内壁クラッディングや家具など、腐食リスクの低い屋内環境で一般的に使用されています。

430グレード

フェライト系ステンレス鋼である430は、乾燥環境での優れた耐食性と優れた耐熱性を特徴としています。オーブン部品や自動車トリムなど、磁気特性や高温酸化に対する耐性が求められる用途でよく選ばれます。

3. 仕様

厚さ: 0.6mm、0.8mm、1.0mm、1.2mm、1.5mm、2.0mm(ご要望に応じてカスタム厚さも可能)

幅

- 標準幅:1000mm、1219mm、1500mm、2000mm

- カスタム幅:最大2500mm(メーカーの能力によります)

長さ

- 標準長:2000mm、2438mm、3000mm、6000mm

- カスタム長:大量注文に対応

公差

- 厚さ:±0.05mm(≤1.0mmの場合); ±0.1mm(>1.0mmの場合)

- 幅/長さ:±2mm

パターンパラメータ

- ビード直径:3~8mm

- ビード高さ:0.3~1.0mm

- 中心間隔:5~15mm

- パターン繰り返し:均一な線形または千鳥配置

4. 表面仕上げ

一次エンボス加工プロセス

明るいビードパターンは、事前に研磨されたステンレス鋼シートをビードデザインが刻まれたローラーに通す冷間圧延エンボス加工プロセスによって作成されます。これにより、正確なパターンの複製と一貫した表面テクスチャが保証されます。

追加の表面処理

- 鏡面研磨:「明るい」外観を向上させ、Ra ≤0.1μmの反射面を実現します。

- ブラッシング(ヘアライン仕上げ):均一で方向性のあるマットなテクスチャを作成し、指紋の視認性を低減します。

- カラーコーティング:電着塗装またはPVD(物理蒸着)コーティングを施すことで、ゴールド、ブロンズ、ブラックなどの色を実現し、パターンテクスチャと装飾的な着色を組み合わせることができます。

- 指紋防止コーティング:保護層を塗布して汚れを最小限に抑え、メンテナンスを容易にします。高接触領域に最適です。

5. 用途

建築装飾

- ホテル、ショッピングモール、高級住宅の内壁/天井クラッディング

- 外壁とカーテンウォール(沿岸地域には316グレードを推奨)

- エレベーター内装、エスカレーターパネル、階段手すり

産業機器

- 機械カバー、コントロールパネル、計器エンクロージャ(手動操作のためのグリップの向上)

- 食品加工機器(衛生基準に適合する304/316グレード)

- 化学貯蔵タンクとパイプライン(腐食環境用の316グレード)

消費者向け製品

- キッチンカウンター、シンクパネル、家電製品ケーシング(201/304グレード)

- 装飾的なテクスチャを備えた家具部品(テーブル、キャビネット)

- プレミアムな美観のための自動車内装(ドアパネル、ダッシュボードトリム)

海洋および沿岸プロジェクト

- ボートデッキ、手すりパネル、沖合プラットフォームの歩道(耐塩水性の316グレード)

6. 梱包と輸送

梱包

- 内側保護:各シートは、傷や埃の付着を防ぐために、帯電防止プラスチックフィルムまたはクラフト紙で個別に包まれています。

- エッジ保護:ハンドリング中のシートエッジを保護するために、フォームストリップまたは段ボールコーナーが適用されています。

- 外側梱包:シートは木製パレット(国際輸送用に処理済み)に積み重ねられ、スチールストラップで固定されています。大量注文の場合、湿気の多い状態での錆を防ぐために、吸湿乾燥剤が入った木枠が使用されます。

輸送

- 海上輸送:適切なラッシングによる標準的なコンテナ積載(20'/40' GP/HQ)。海洋グレードの梱包(316グレードのシートには、追加の防食対策が必要な場合があります)。

- 航空輸送:緊急の注文に適しており、貨物重量を最小限に抑えるための軽量梱包。

- 取り扱い上の注意:輸送中は雨や直射日光にさらさないでください。シートの変形を防ぐために、乾燥した換気の良い倉庫に平置きで保管してください。

![]()

![]()

![]()

![]()

推薦されたプロダクト