-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Aste di rettifica in acciaio inossidabile 316F: durata superiore e finitura liscia

| Luogo di origine | Cina |

|---|---|

| Marca | Delta |

| Certificazione | ISO 9001 |

| Numero di modello | 316F |

| Quantità di ordine minimo | 500 kg |

| Prezzo | 3-4 USD/Kg |

| Imballaggi particolari | scatola di legno o rivestimento in carta impermeabile |

| Tempi di consegna | 5 - 10 giorni |

| Termini di pagamento | T/T, Western Union |

| Capacità di alimentazione | 50 tonnellate al mese |

| Nome dei prodotti | Barra in acciaio inossidabile 316F | Diametro | 10 - 350mm |

|---|---|---|---|

| Lunghezza | 6m o tagliare qualsiasi lunghezza come richiesta | Superficie | Sottaceti o brillanti |

| Servizio | Taglio | Standard | ASTM Din GB en |

| Altri prodotti | barra rotonda, barra quadrata, barra piatta.etc | Tecnica | Laminato caldo |

| Evidenziare | Aste di rettifica in acciaio inossidabile 316F,Aste in acciaio inossidabile con finitura liscia,Barre di rettifica in acciaio inossidabile resistenti |

||

316F Barre di macinazione in acciaio inossidabile Durabilità superiore e finitura liscia

Specifica dei prodotti

| Nome dei prodotti | 316F Barra rotonda in acciaio inossidabile |

| Grado |

303,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660C276,600,601,625,718,800800H,825,926. ecc |

| Diametro dei prodotti | φ3 mm - φ350 mm |

| Distanze | 6 m/pcs o tagliando su richiesta |

| Superficie | Finitura di decapaggio, finitura lucida |

| Norme | ASTM JIS, GB, DIN EN |

| Servizio | Taglio |

| Altre forme | Quadrato, piatto, esagonale, rotondo, ecc. |

| Porto di carico | Porto di Shanghai |

| MOQ | 50 kg |

316F Barre di rettifica in acciaio inossidabile

Durabilità superiore e finitura liscia**

Il...316F barre di macinazione in acciaio inossidabileè un materiale per utensili industriali ad alte prestazioni progettato per applicazioni che richiedonodurabilità ineguagliabile, comportamento di rettifica di precisione e resistenza a lungo termine alla corrosione e all'usura meccanicaCome versione di lavorazione libera migliorata dell'acciaio inossidabile 316 ampiamente utilizzato, il 316F offre tutti i noti vantaggi della serie 316, offrendo al contempolavorabilità superiore, proprietà di taglio più pulite e miglioramento della liscezza della superficie.

Prodotto con un tenore di zolfo accuratamente regolato, 316F in acciaio inossidabileeccellenti prestazioni di rottura dei frammenti, che lo rende ideale per la macinazione, la debburring, la modellazione, la lucidatura e i processi di finitura di precisione in una varietà di industrie.Ingegneria navale, apparecchiature alimentari, aerospaziale, strumentazione, attrezzature mediche, lavorazione ad alta precisione e fabbricazione chimica.

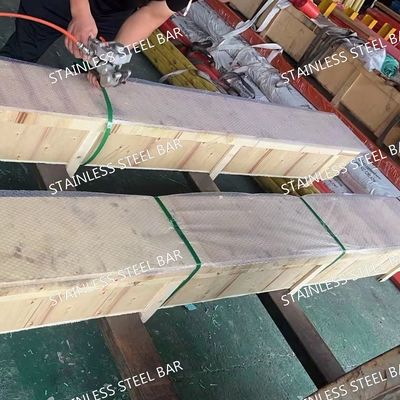

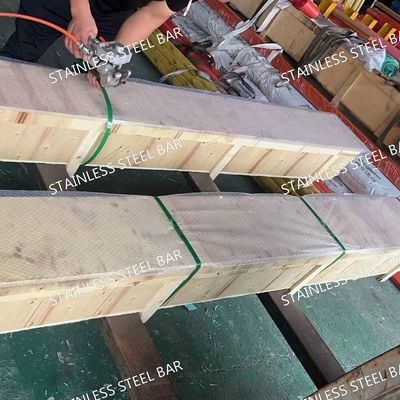

Visualizzazione del prodotto

Le barre di macinazione in acciaio inossidabile 316F sono progettate per soddisfare le rigide esigenze della produzione moderna.

-

Risistenza eccezionale alla corrosione, anche in ambienti ricchi di cloruri o acidi

-

Funzionamento strutturale affidabilea carico elevato o a temperatura elevata

-

Eccellente lavorabilità, consentendo una macinazione più liscia e risultati coerenti

-

Deformazione minima, anche durante ripetuti cicli di macinazione

-

Finitura uniforme e pulita, adatto per la lucidatura ad alta precisione

Sia che siano utilizzati per strumenti di rettifica di precisione, alberi, perni, rifiniture di componenti o preparazione superficiale nei sistemi industriali, le barre di rettifica 316F garantiscono prestazioni affidabili e durature.

Principali vantaggi delle barre di rettifica in acciaio inossidabile 316F

1. Robusta resistenza alla corrosione in ambienti difficili

316F contiene entrambinickel (Ni)- emolibdeno (Mo), fornendo una forte difesa contro:

-

Corrosione da acqua salata

-

Cloruro indotto a buco

-

Esposizione ad acidi e basi

-

Ambienti umidi o ad alta salinità

-

Contaminazione da processi chimici

Questo rende le barre ideali per apparecchiature marine, alimentari, farmaceutiche e chimiche.

2. prestazioni di rettifica superiori

A differenza dell'acciaio inossidabile standard, il contenuto ottimizzato di zolfo nel 316F aumenta notevolmente:

-

Lividità di taglio

-

Evasione dei chip

-

Efficienza di macinazione

-

Vita dell'utensile

-

Consistenza dimensionale tra i lotti di produzione

Queste caratteristiche riducono l'accumulo di calore, l'usura degli utensili e le incoerenze superficiali, creando una finitura più liscia anche in operazioni di rettifica ad alta precisione.

3Alta stabilità strutturale e resistenza meccanica

316F offre elevate prestazioni meccaniche, tra cui:

-

Stabilità dimensionale stretta

-

Resistenza alla trazione e alla resa affidabili

-

Ottima resistenza agli urti e alle vibrazioni

-

Basso rischio di crepa durante la macinazione

La sua struttura robusta garantisce che le barre rimangano rette, affidabili e uniformi, cosa essenziale in ambienti di produzione che richiedono una precisione impeccabile.

4. Superficie pulita, liscia e priva di difetti

Le barre di macinazione 316F sono caratterizzate:

-

Superficie esterna uniforme e uniforme

-

Purezza metallurgica di alta qualità

-

Difetti interni minimi

-

Potenziale di lucidatura superiore

Di conseguenza, le barre sono perfette per applicazioni di finitura superficiale come la rettifica di stampi, la lucidatura di dispositivi medici e la finitura di componenti semiconduttori.

5Proprietà igieniche e di bassa manutenzione

L'acciaio inossidabile 316F è facile da pulire, non reattivo e adatto per ambienti che richiedono un rigoroso controllo sanitario.

-

Macchine per la produzione alimentare

-

Sistemi di trasformazione delle bevande

-

Strumenti per apparecchiature mediche

-

Componenti per cucine industriali

I suoi vantaggi igienici rendono il funzionamento a lungo termine sicuro e affidabile.

Visualizzazione dei dati tecnici

Qui di seguito sono riportate le specifiche di riferimento per le barre di rettifica in acciaio inossidabile 316F.

Composizione chimica

| Elemento | Percentuale (%) |

|---|---|

| Carbonio (C) | ≤ 0.08 |

| Silicio (Si) | ≤ 100 |

| Manganese (Mn) | ≤ 200 |

| Fosforo (P) | ≤ 0.045 |

| Sulfuro (S) | 0.10 ¢ 0.30 |

| Cromo (Cr) | 16.0 ¢18.0 |

| Nilo (Ni) | 10.0 ¢14.0 |

| Molibdeno (Mo) | 2.0 ¢3.0 |

| Ferro (Fe) | Bilancio |

Proprietà fisiche

| Immobili | Valore tipico |

|---|---|

| Densità | 70,98 g/cm3 |

| Distanza di fusione | 1375-1400°C |

| Conduttività termica | 16·17 W/m·K |

| Calore specifico | 500 J/kg·K |

| Resistenza elettrica | 74 μΩ·cm |

| Proprietà magnetiche | Non magnetici allo stato di ricottura |

Proprietà meccaniche

| Immobili | Valore |

|---|---|

| Resistenza alla trazione | ≥ 515 MPa |

| Forza di resa | ≥ 205 MPa |

| L'allungamento | ≥ 40% |

| Durezza | 150 ¢ 190 HB |

| Modulo di elasticità | 193 GPa |

| Resistenza agli urti | Eccellente. |

Dimensioni e tolleranze standard

| Intervallo di diametro | Opzioni di lunghezza | Tolleranza dimensionale | Diritta | Finitura superficiale |

|---|---|---|---|---|

| 2 ̊6 mm | 100 ‰ 2000 mm | ± 0,005 mm | 0.1 mm/m | Fine / lucidato |

| 7 ̊12 mm | 100 ‰ 3000 mm | ± 0,01 mm | 0.15 mm/m | Listo / lucidato |

| 13 ̊25 mm | 100 ‰ 4000 mm | ± 0,02 mm | 0.2 mm/m | Polito / spazzolato |

| Dimensioni personalizzate | Su richiesta | Costumi | Costumi | Costumi |

Applicazioni principali

Le barre di triturazione in acciaio inossidabile 316F svolgono funzioni critiche in una vasta gamma di settori.

1Ingegneria marina e offshore

La forte resistenza al cloruro del 316F ̊ lo rende indispensabile in ambienti marini.

-

Strumenti di rettifica per componenti di navi

-

Strumenti per la finitura degli alberi

-

Preparazione della superficie delle attrezzature subacquee

-

Parti di precisione anticorrosione

La sua resistenza all'acqua di mare e alla crepa da stress garantisce un'affidabilità a lungo termine.

2Aerospaziale e aviazione

I componenti di precisione nel settore aerospaziale si basano su materiali con elevata integrità strutturale e finitura superficiale pulita.

Applicazioni tipiche:

-

Altre macchine per la produzione di calzature

-

Macchine per la lavorazione del ferro o del carbonio

-

Barre di lucidatura per parti inossidabili di aeromobili

L'elevata stabilità del 316F consente di rispettare le rigide tolleranze richieste nella produzione aerospaziale.

3Produzione di dispositivi medici

La natura igienica e a bassa reattività del 316F lo rende adatto per la finitura di utensili medici e dentali.

Le applicazioni comprendono:

-

Smalzaggio di strumenti chirurgici

-

Formazione di utensili ortopedici

-

Finitura superficiale di componenti medici

-

Lavori di macinazione ad alta pulizia

Le barre garantiscono superfici lisce con un rischio minimo di contaminazione.

4Apparecchiature di lavorazione chimica

316F resiste all'esposizione a sostanze chimiche, acidi e solventi, rendendolo un materiale affidabile nell'industria chimica.

Gli usi includono:

-

Strumenti di rottura e di manutenzione per reattori chimici

-

Apparecchi di finitura delle condotte

-

Strumenti utilizzati nella fabbricazione di apparecchi di laboratorio

La resistenza alla corrosione prolunga significativamente la durata di vita degli utensili in ambienti chimicamente aggressivi.

5. Macchine e utensili ad alta precisione

Per i produttori che richiedono finiture superficiali estremamente raffinate, il 316F offre un valore ineguagliabile.

Applicazioni:

-

Altre macchine per la lavorazione del calore

-

Pini e alberi di precisione

-

Apparecchi di finitura a stampo

-

Prodotti per la fabbricazione di macchine e apparecchi per la fabbricazione di macchine per la fabbricazione di macchine

La sua maggiore lavorabilità garantisce prestazioni stabili in grandi cicli di produzione.

6Industria elettronica e semiconduttori

Dove la pulizia e la bassa generazione di particolato sono importanti, il 316F eccelle.

Esempi di utilizzo:

-

Macchine e apparecchi per la lavorazione di materie plastiche

-

Strumenti di allineamento e taratura

-

Altri apparecchi per la manutenzione di apparecchiature semiconduttrici

Il suo comportamento di rettificazione riduce al minimo la contaminazione, che è fondamentale per gli ambienti delle stanze pulite.

Vantaggi rispetto all'acciaio inossidabile 316

Il 316F non è semplicemente una variante, ma offre chiarissimi miglioramenti delle prestazioni per applicazioni di lavorazione, macinatura e lucidatura.

| Caratteristica | Norma 316 | 316F Acciaio inossidabile |

|---|---|---|

| Capacità di lavorazione | Moderato | Superiore (di grado di lavorazione libera) |

| Efficienza della macinazione | - Bene. | Smaltimento alto e liscio |

| Contenuto di zolfo | Basso | Ottimizzato per la rottura dei chip |

| Qualità della finitura superficiale | - Bene. | Eccellente, a rispecchiatura. |

| Riduzione dell'usura degli attrezzi | Moderato | Riduzione dell'usura e del calore |

| Performance nel lavoro di precisione | - Bene. | Esclusivo |

Questi vantaggi rendono il 316F la scelta preferita per le operazioni di rettifica che richiedono precisione e durata.

Fabbricazione e controllo qualità

Le nostre barre di macinazione in acciaio inossidabile 316F sono prodotte utilizzando tecnologie di produzione di precisione per garantire una qualità di prim'ordine.

Metodi di produzione includono:

-

Disegno a freddoper migliorare la resistenza e la precisione dimensionale

-

Macinatura CNCper tolleranze di diametro precise

-

Polizione automaticaper ottenere superfici uniformi e lisce

-

Annellazioneper migliorare la lavorabilità e la stabilità della struttura

-

Prova non distruttiva (NDT)per garantire la solidità interna

Passi di controllo della qualità

-

Verifica della composizione chimica

-

Controllo della reticolazione

-

Valutazione delle microstrutture

-

Prova di durezza

-

Misurazione della rugosità superficiale

-

Controlli di accuratezza dimensionale

Ogni canna è prodotta per soddisfare severi standard industriali di qualità.

Opzioni di personalizzazione

Offriamo un'ampia personalizzazione per soddisfare le diverse esigenze industriali:

-

Diametri e lunghezze su misura

-

Tolleranze personalizzate

-

Superfici di alta lucidità o satinate

-

Opzioni di trattamento termico

-

Servizi di OEM e di fabbricazione a granel

Che si tratti di attrezzi specializzati o di produzione di massa, offriamo soluzioni flessibili.

Manipolazione, conservazione e manutenzione

Per preservare le prestazioni e la durata di vita delle barre di macinazione 316F, seguire le seguenti linee guida:

-

Tenere le barre in unarea di stoccaggio pulita e asciutta

-

Evitare il contatto con acciaio al carbonio per evitare la contaminazione

-

Uso pulitodetergenti neutri o soluzioni a base di alcol

-

Usare guanti durante la manipolazione per evitare la corrosione delle impronte digitali

-

Applicare olio protettivo per lunghi periodi di conservazione

Queste pratiche mantengono l'integrità della superficie delle barre e proteggono dalla contaminazione.

Conclusioni

316F Barre di rettifica in acciaio inossidabileoffrire una combinazione diDurabilità superiore, eccellente resistenza alla corrosione, lavorabilità ottimizzata e prestazioni di rettifica eccezionaliLe loro migliori caratteristiche di lavorazione libera e le loro proprietà meccaniche stabili le rendono la scelta ideale per le industrie che richiedonomacinazione di precisione, prestazioni durature e qualità superficiale.

Sia che le vostre applicazioni riguardino ambienti marini, componenti aerospaziali, dispositivi medici, apparecchiature alimentari o sistemi di produzione ultra-precisi,Le barre di macinazione 316F forniscono risultati affidabili e costanti che contribuiscono a migliorare la produttività e ridurre i tempi di fermo attrezzatura.

Perle specifiche personalizzate, il supporto tecnico o gli ordini in blocco, non esitate a contattarci. Offriamo soluzioni su misura per soddisfare le vostre esigenze.

![]()

![]()

![]()

![]()