-

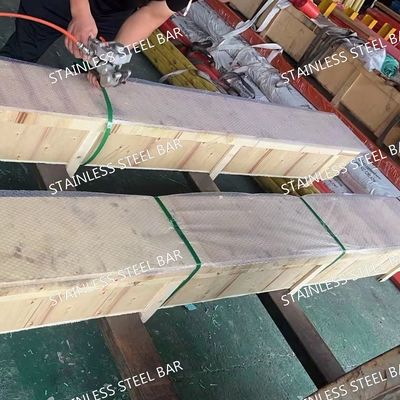

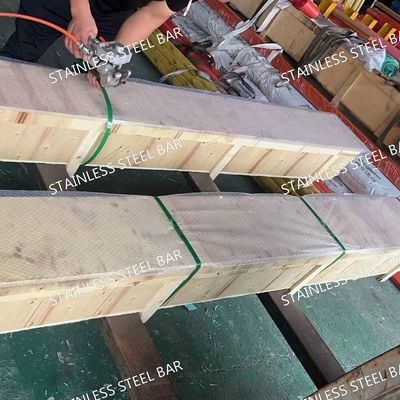

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

316F-grindstangen van roestvrij staal: superieure duurzaamheid en gladde afwerking

| Productennaam | 316F roestvrijstalen staaf | Diameter | 10 - 350mm |

|---|---|---|---|

| Lengte | 6m of het afsnijden van een lengte als verzoek | Oppervlak | Peperd of helder |

| Dienst | Snijden | Standaard | Astm din gb en |

| Andere producten | Ronde bar, vierkante bar, platte bar.etc | Techniek | Heet opgerold |

| Markeren | 316F slijpstaven van roestvrij staal,met een breedte van niet meer dan 50 mm,durable stainless steel grinding bars |

||

316F Roestvrijstalen Slijpstaven Superieure Duurzaamheid & Gladde Afwerking

Productspecificatie

| Productnaam | 316F Roestvrijstalen Ronde Staaf |

| Kwaliteit |

303,304,304L,309S,310S,310H,316L,316Ti,316H,317L,321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800,800H,825,926.etc |

| Producten Diameter Bereik | φ3mm - φ350mm |

| Lengte | 6m/stuk of op maat gesneden lengte op aanvraag |

| Oppervlak | Beitsafwerking, heldere afwerking |

| Standaard | ASTM JIS,GB,DIN EN |

| Service | Snijden |

| Andere Vorm | Vierkant, Plat, Zeshoekig, Rond.etc |

| Laadpoort | Shanghai Haven |

| MOQ | 50 kg |

316F Roestvrijstalen Slijpstaven

Superieure Duurzaamheid & Gladde Afwerking**

De316F roestvrijstalen slijpstaafis een hoogwaardig industrieel gereedschapsmateriaal dat is ontworpen voor toepassingen dieongeëvenaarde duurzaamheid, precisie slijpgedrag en langdurige weerstand tegen corrosie en mechanische slijtage vereisen. Als een verbeterde, gemakkelijk te bewerken versie van het veelgebruikte 316 roestvrij staal, biedt 316F alle bekende voordelen van de 316-serie en biedt tegelijkertijdsuperieure bewerkbaarheid, schonere snijeigenschappen en een verbeterde oppervlaktegladheid.

Vervaardigd met een zorgvuldig aangepast zwavelgehalte, vertoont 316F roestvrij staaluitstekende spaanbreekprestaties, waardoor het ideaal is voor slijpen, ontbramen, vormen, polijsten en precisie afwerkingsprocessen in een verscheidenheid aan industrieën. Deze eigenschappen maken 316F slijpstaven bijzonder waardevol inscheepsbouw, voedselapparatuur, lucht- en ruimtevaart, instrumentatie, medische gereedschappen, precisiebewerking en chemische productie.

Productoverzicht

316F roestvrijstalen slijpstaven zijn ontworpen om te voldoen aan de strenge eisen van de moderne productie. Ze bieden:

-

Uitzonderlijke corrosiebestendigheid, zelfs in chloride-rijke of zure omgevingen

-

Betrouwbare structurele prestatiesin omstandigheden met hoge belasting of hoge temperaturen

-

Uitstekende bewerkbaarheid, waardoor soepeler slijpen en consistente resultaten mogelijk zijn

-

Minimale vervorming, zelfs tijdens herhaalde slijpcycli

-

Een uniforme, schone oppervlakteafwerking, geschikt voor hoogwaardig polijsten

Of ze nu worden gebruikt voor precisie slijpgereedschappen, assen, pennen, componenten afwerking of oppervlaktevoorbereiding in industriële systemen, 316F slijpstaven zorgen voor betrouwbare, duurzame prestaties.

Belangrijkste Voordelen van 316F Roestvrijstalen Slijpstaven

1. Robuuste Corrosiebestendigheid in Ruwe Omgevingen

316F bevat zowelnikkel (Ni)alsmolybdeen (Mo), wat een sterke bescherming biedt tegen:

-

Zoutwatercorrosie

-

Door chloride veroorzaakte putcorrosie

-

Blootstelling aan zuren en basen

-

Vochtige of zoutrijke omgevingen

-

Verontreiniging door chemische processen

Dit maakt de staven ideaal voor marine-, voedselverwerkings-, farmaceutische en chemische apparatuur.

2. Superieure Slijpprestaties

In tegenstelling tot standaard roestvrij staal, verbetert het geoptimaliseerde zwavelgehalte in 316F merkbaar:

-

Snijgladheid

-

Spaanverwijdering

-

Slijpefficiëntie

-

Levensduur van het gereedschap

-

Dimensionale consistentie over productiebatches

Deze eigenschappen verminderen warmteontwikkeling, gereedschapsslijtage en oppervlakte-onregelmatigheden, waardoor een gladdere afwerking ontstaat, zelfs bij precisie slijpbewerkingen.

3. Hoge Structurele Stabiliteit en Mechanische Sterkte

316F levert sterke mechanische prestaties, waaronder:

-

Strakke dimensionale stabiliteit

-

Betrouwbare trek- en vloeigrens

-

Uitstekende weerstand tegen impact en trillingen

-

Laag risico op scheuren tijdens het slijpen

De robuuste structuur zorgt ervoor dat de staven recht, betrouwbaar en uniform blijven, wat essentieel is in productieomgevingen die onberispelijke precisie vereisen.

4. Schoon, Glad en Defectvrij Oppervlak

316F slijpstaven hebben:

-

Een consistent, uniform buitenoppervlak

-

Hoge kwaliteit metallurgische zuiverheid

-

Minimale interne defecten

-

Superieur polijstpotentieel

Als gevolg hiervan zijn de staven perfect voor oppervlakteafwerkingstoepassingen zoals matrijslijpen, het polijsten van medische apparaten en het afwerken van halfgeleidercomponenten.

5. Weinig Onderhoud en Hygiënische Eigenschappen

316F roestvrij staal is gemakkelijk schoon te maken, niet-reactief en geschikt voor omgevingen die strenge sanitaire controle vereisen. Het wordt veel gebruikt in:

-

Machines voor voedselproductie

-

Systemen voor drankverwerking

-

Gereedschappen voor medische apparatuur

-

Industriële keukencomponenten

De hygiënische voordelen maken langdurige werking veilig en betrouwbaar.

Overzicht Technische Gegevens

Hieronder staan veelgebruikte specificaties voor 316F roestvrijstalen slijpstaven.

Chemische Samenstelling

| Element | Percentage (%) |

|---|---|

| Koolstof (C) | ≤ 0,08 |

| Silicium (Si) | ≤ 1,00 |

| Mangaan (Mn) | ≤ 2,00 |

| Fosfor (P) | ≤ 0,045 |

| Zwavel (S) | 0,10–0,30 |

| Chroom (Cr) | 16,0–18,0 |

| Nikkel (Ni) | 10,0–14,0 |

| Molybdeen (Mo) | 2,0–3,0 |

| IJzer (Fe) | Balans |

Fysische Eigenschappen

| Eigenschap | Typische Waarde |

|---|---|

| Dichtheid | 7,98 g/cm³ |

| Smeltbereik | 1375–1400°C |

| Thermische Geleidbaarheid | 16–17 W/m·K |

| Specifieke Warmte | 500 J/kg·K |

| Elektrische Weerstand | 74 µΩ·cm |

| Magnetische Eigenschappen | Niet-magnetisch in gegloeide toestand |

Mechanische Eigenschappen

| Eigenschap | Waarde |

|---|---|

| Treksterkte | ≥ 515 MPa |

| Vloeigrens | ≥ 205 MPa |

| Rek | ≥ 40% |

| Hardheid | 150–190 HB |

| Elasticiteitsmodulus | 193 GPa |

| Slagvastheid | Uitstekend |

Standaard Maten & Toleranties

| Diameter Bereik | Lengte Opties | Dimensionale Tolerantie | Rechtheid | Oppervlakteafwerking |

|---|---|---|---|---|

| 2–6 mm | 100–2000 mm | ±0,005 mm | 0,1 mm/m | Fijn / Gepolijst |

| 7–12 mm | 100–3000 mm | ±0,01 mm | 0,15 mm/m | Glad / Gepolijst |

| 13–25 mm | 100–4000 mm | ±0,02 mm | 0,2 mm/m | Gepolijst / Geborsteld |

| Aangepaste Maten | Op aanvraag | Aangepast | Aangepast | Aangepast |

Primaire Toepassingen

316F roestvrijstalen slijpstaven dienen kritieke functies in een breed scala aan industrieën. Hieronder staan belangrijke sectoren waar de staven uitzonderlijke prestaties leveren.

1. Marine & Offshore Engineering

De sterke chloridebestendigheid van 316F maakt het onmisbaar in maritieme omgevingen. Toepassingen zijn onder meer:

-

Slijpgereedschappen voor scheepsonderdelen

-

Afwerking gereedschappen voor assen

-

Oppervlaktevoorbereiding van onderwaterapparatuur

-

Anti-corrosie precisie onderdelen

De weerstand tegen zeewater en spanningsscheuren zorgt voor langdurige betrouwbaarheid.

2. Lucht- en Ruimtevaart

Precisiecomponenten in de lucht- en ruimtevaartsector vertrouwen op materialen met een hoge structurele integriteit en een schone oppervlakteafwerking.

Typische toepassingen:

-

Gereedschapsstaven voor de voorbereiding van turbinecomponenten

-

Slijpassen voor precisie-assemblages

-

Polijststaven voor roestvrijstalen onderdelen van vliegtuigen

De hoge stabiliteit van 316F ondersteunt de nauwe toleranties die vereist zijn in de lucht- en ruimtevaartproductie.

3. Productie van Medische Apparaten

De hygiënische, lage reactiviteit van 316F maakt het geschikt voor het afwerken van medische en tandheelkundige gereedschappen.

Toepassingen zijn onder meer:

-

Slijpen van chirurgische instrumenten

-

Vormgeven van orthopedische gereedschappen

-

Oppervlakteafwerking van medische componenten

-

Slijptaken met hoge reinheid

De staven zorgen voor gladde oppervlakken met minimaal contaminatierisico.

4. Apparatuur voor Chemische Verwerking

316F is bestand tegen blootstelling aan chemicaliën, zuren en oplosmiddelen, waardoor het een vertrouwd materiaal is in de chemische industrie.

Gebruik omvat:

-

Slijp- en onderhoudsgereedschappen voor chemische reactoren

-

Apparatuur voor het afwerken van pijpleidingen

-

Gereedschappen die worden gebruikt bij de productie van laboratoriumapparatuur

De corrosiebestendigheid verlengt de levensduur van gereedschappen aanzienlijk in chemisch agressieve omgevingen.

5. Precisiebewerking & Gereedschapsmakerij

Voor fabrikanten die extreem verfijnde oppervlakteafwerkingen vereisen, biedt 316F een ongeëvenaarde waarde.

Toepassingen:

-

Matrijs slijpstaven

-

Precisie pennen en assen

-

Apparatuur voor het afwerken van matrijzen

-

Polijststaven voor productie met nauwe toleranties

De verbeterde bewerkbaarheid garandeert stabiele prestaties over grote productiecycli.

6. Elektronica Productie & Halfgeleiderindustrie

Waar reinheid en lage deeltjesgeneratie belangrijk zijn, blinkt 316F uit.

Gebruiksvoorbeelden:

-

Slijpstaven voor wafervoorbereiding

-

Uitlijnings- en kalibratiegereedschappen

-

Onderhoudsstaven voor halfgeleiderapparatuur

Het gladde slijpgedrag minimaliseert contaminatie—kritisch voor cleanroom-omgevingen.

Voordelen Ten Opzichte van Standaard 316 Roestvrij Staal

316F is niet zomaar een variant—het biedt duidelijke prestatieverbeteringen voor bewerkings-, slijp- en polijsttoepassingen.

| Eigenschap | Standaard 316 | 316F Roestvrij Staal |

|---|---|---|

| Bewerkbaarheid | Matig | Superieur (gemakkelijk te bewerken kwaliteit) |

| Slijpefficiëntie | Goed | Hoog, glad slijpen |

| Zwavelgehalte | Laag | Geoptimaliseerd voor spaanbreken |

| Kwaliteit Oppervlakteafwerking | Goed | Uitstekend, spiegelbaar |

| Gereedschapsslijtage Vermindering | Matig | Verminderde slijtage en warmte |

| Prestaties in Precisiewerk | Goed | Uitzonderlijk |

Deze voordelen maken 316F de voorkeurskeuze voor slijpbewerkingen die nauwkeurigheid en duurzaamheid vereisen.

Productie & Kwaliteitscontrole

Onze 316F roestvrijstalen slijpstaven worden geproduceerd met behulp van precisieproductietechnologieën om topkwaliteit te garanderen.

Productiemethoden Omvatten

-

Koudtrekkenom de sterkte en dimensionale nauwkeurigheid te verbeteren

-

CNC-slijpenvoor precieze diameter toleranties

-

Geautomatiseerd polijstenom uniforme, gladde oppervlakken te bereiken

-

Gloeienom de bewerkbaarheid en structurele stabiliteit te verbeteren

-

Niet-destructief testen (NDT)om de interne degelijkheid te garanderen

Kwaliteitscontrole Stappen

-

Verificatie van chemische samenstelling

-

Rechtheidsinspectie

-

Evaluatie van de microstructuur

-

Hardheidstesten

-

Oppervlakte ruwheidsmeting

-

Controles van dimensionale nauwkeurigheid

Elke staaf wordt geproduceerd om te voldoen aan strenge industriële kwaliteitsnormen.

Aanpassingsopties

We bieden uitgebreide aanpassingen om aan verschillende industriële eisen te voldoen:

-

Aangepaste diameters en lengtes

-

Op maat gemaakte toleranties

-

Hoogglans of satijn oppervlakken

-

Warmtebehandelingsopties

-

OEM & bulk productie services

Of het nu gaat om gespecialiseerde slijpgereedschappen of massaproductie, wij bieden flexibele oplossingen.

Behandeling, Opslag & Onderhoud

Om de prestaties en levensduur van uw 316F slijpstaven te behouden, volgt u deze richtlijnen:

-

Bewaar staven in eenschone, droge opslagruimte

-

Vermijd contact met koolstofstaal om contaminatie te voorkomen

-

Reinig metneutrale reinigingsmiddelen of oplossingen op alcoholbasis

-

Draag handschoenen tijdens het hanteren om vingerafdrukcorrosie te voorkomen

-

Breng beschermende olie aan voor langere opslagperioden

Deze praktijken behouden de oppervlakte-integriteit van de staven en beschermen tegen contaminatie.

Conclusie

316F Roestvrijstalen Slijpstavenbieden een combinatie vansuperieure duurzaamheid, uitstekende corrosiebestendigheid, geoptimaliseerde bewerkbaarheid en uitzonderlijke slijpprestaties. Hun verbeterde gemakkelijk te bewerken eigenschappen en stabiele mechanische eigenschappen maken ze de ideale keuze voor industrieën dieprecisieslijpen, langdurige prestaties en superieure oppervlaktekwaliteit vereisen.

Of uw toepassingen nu maritieme omgevingen, lucht- en ruimtevaartcomponenten, medische apparaten, voedselapparatuur of ultra-precieze productiesystemen omvatten, 316F slijpstaven leveren betrouwbare en consistente resultaten die de productiviteit helpen verbeteren en de uitvaltijd van gereedschappen verminderen.

Vooraangepaste specificaties, technische ondersteuning of bulkbestellingen, neem gerust contact met ons op—wij bieden oplossingen op maat om aan uw exacte eisen te voldoen.

![]()

![]()

![]()

![]()