-

Striscia di acciaio inossidabile

-

Strato di acciaio inossidabile

-

Piatto di acciaio inossidabile

-

tubo di acciaio inossidabile

-

Acciaio inossidabile Antivari

-

Bobina d'acciaio galvanizzata

-

Piatto d'acciaio

-

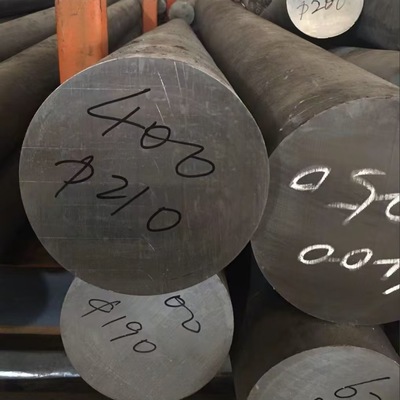

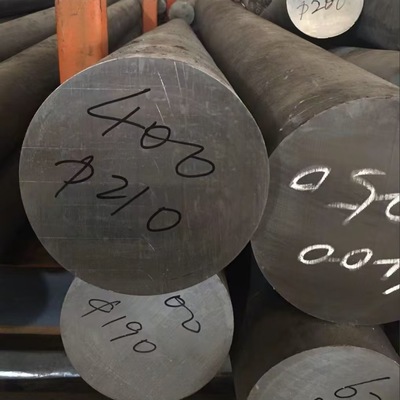

tondino d'acciaio

-

lega di nichel

-

Tubo d'acciaio senza cuciture

-

Fascio di acciaio inossidabile

-

Strato del piatto di rame

-

Tondino di rame

-

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Raian IonescuQualità materiale molto buona. abbiamo cooperare più di 10 anni. Vendono i generi dei lotti di materiale d'acciaio. Tutta la qualità materiale buona. Essi dovere per tutta la qualità materiale. Stiamo spianando per continuare a cooperare in futuro con loro

Industrial-Grade Monel K500 Round Bar High Hardness, Anti-Oxidation Properties for Valve Stems, Shafts & Critical Engineering Uses

| Luogo di origine | Cina |

|---|---|

| Marca | DELTA |

| Certificazione | ISO |

| Numero di modello | Monel K500 |

| Quantità di ordine minimo | 10 kg |

| Prezzo | 30 - 35 USD/Kg |

| Imballaggi particolari | imballaggio standard per l'esportazione |

| Tempi di consegna | 5 - 12 giorni in base alla quantità |

| Termini di pagamento | L/C, T/T, Western Union |

| Capacità di alimentazione | 3 tonnellate a settimana |

| Prodotti | tondino del monel k500 | Grado | Monel K500 |

|---|---|---|---|

| Diametro | 10 - 350mm | Lunghezza | taglio su misura di qualsiasi lunghezza su richiesta |

| Standard | Astm en | Servizio | Taglio |

| Porta di caricamento | Shanghai Port | Superficie | Nero, luminoso |

| Evidenziare | Monel K500 round bar high hardness,Industrial-grade Monel K500 valve stems,Nickel alloy round bar anti-oxidation |

||

Industrial-Grade Monel K500 Round Bar High Hardness, Anti-Oxidation Properties for Valve Stems, Shafts & Critical Engineering Uses

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725 Incoloy series: 800 800H 825 925 Hastelloy series: B,B2,B3,C,C-276,C-4,C-22 Pure: Ni200, Ni201 |

||

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

|

Width

|

1~1500mm

|

||

|

Square bar

|

Size: 4*4-100*100mm

|

||

|

Length

|

2m, 5.8m, 6m, or as required.

|

||

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

||

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

||

|

Package

|

Export standard package, bundled or be required.

The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

||

Industrial-Grade Monel K500 Round Bar High Hardness, Anti-Oxidation Properties for Valve Stems, Shafts & Critical Engineering Uses

1. Introduction to Monel K500 Round Bar

Monel K500 round bar is a premium nickel-copper alloy round bar engineered for industrial applications demanding exceptional durability, corrosion resistance, and mechanical strength. Derived from the base Monel 400 alloy, Monel K500 is further strengthened through a precipitation hardening process—a heat treatment that forms fine intermetallic precipitates (primarily nickel-aluminum and nickel-titanium phases) within its microstructure. This modification elevates its hardness, tensile strength, and wear resistance far beyond standard Monel 400, while retaining the base alloy’s outstanding resistance to corrosion in harsh environments (e.g., seawater, acidic/alkaline solutions, and high-temperature gases).

As a “critical engineering material,” industrial-grade Monel K500 round bar is manufactured to tight dimensional tolerances and strict quality controls, ensuring consistency in performance across sectors like oil and gas, marine engineering, aerospace, and chemical processing. Its round shape makes it ideal for machining into precision components (e.g., valve stems, shafts, and fasteners) where uniform strength and dimensional stability are non-negotiable.

2. Key Technical Specifications

Monel K500 round bar adheres to global material standards, with specifications covering chemical composition, mechanical properties, and dimensional tolerances. Below is a detailed breakdown:

2.1 Chemical Composition (Typical, by Weight %)

The alloy’s corrosion resistance and hardenability stem from its precisely balanced chemistry:

|

Element |

Content Range |

Role |

|---|---|---|

|

Nickel (Ni) |

63.0 – 67.0% |

Primary base metal; provides corrosion resistance and alloy ductility |

|

Copper (Cu) |

27.0 – 33.0% |

Enhances strength and resistance to seawater/chemical corrosion |

|

Aluminum (Al) |

2.3 – 3.1% |

Enables precipitation hardening; boosts hardness and tensile strength |

|

Titanium (Ti) |

0.35 – 0.85% |

Works with Al to form precipitates; refines microstructure |

|

Iron (Fe) |

≤ 2.0% |

Minimizes impurities; maintains alloy stability |

|

Manganese (Mn) |

≤ 1.5% |

Improves workability during hot/cold forming |

|

Silicon (Si) |

≤ 0.5% |

Reduces casting defects; supports machining performance |

|

Carbon (C) |

≤ 0.25% |

Controls carbide formation; prevents brittleness |

2.2 Mechanical Properties (After Precipitation Hardening)

These properties define the round bar’s ability to withstand mechanical stress and wear in critical applications:

|

Property |

Metric Unit |

Imperial Unit |

Test Standard |

|---|---|---|---|

|

Tensile Strength |

≥ 1100 MPa |

≥ 160 ksi |

ASTM B865 |

|

Yield Strength (0.2% Offset) |

≥ 790 MPa |

≥ 115 ksi |

ASTM B865 |

|

Elongation (in 50 mm) |

≥ 15% |

≥ 15% |

ASTM B865 |

|

Hardness (Rockwell C) |

30 – 40 HRC |

30 – 40 HRC |

ASTM E18 |

|

Fatigue Strength (10⁷ cycles) |

≥ 480 MPa |

≥ 70 ksi |

ASTM E466 |

2.3 Dimensional Tolerances

Industrial-grade round bars are produced with tight tolerances to ensure compatibility with precision machining:

-

Diameter Range: 6 mm – 300 mm (0.25 in – 12 in)

-

Tolerance Class: EN 10278 Class h9 (for cold-finished bars) or Class h11 (for hot-rolled bars)

-

Straightness: ≤ 1 mm/m (0.05 in/ft)

-

Surface Finish: Hot-rolled (Rz 100 – 200 μm) or Cold-drawn (Rz 10 – 25 μm, for high-precision needs)

3. Core Performance Advantages

Monel K500 round bar’s popularity in critical engineering stems from its unique combination of performance traits:

3.1 Exceptional Hardness & Wear Resistance

Thanks to precipitation hardening, its Rockwell C hardness (30–40 HRC) is 2–3 times higher than Monel 400. This makes it resistant to abrasion, galling, and deformation—critical for components like valve stems and shafts that operate under continuous friction.

3.2 Superior Corrosion Resistance

It retains Monel 400’s “all-environment” corrosion resistance:

-

Resists pitting, crevice corrosion, and stress corrosion cracking (SCC) in seawater, brackish water, and marine atmospheres.

-

Withstands exposure to organic acids (e.g., acetic acid), inorganic acids (e.g., sulfuric acid, at low concentrations), and alkaline solutions.

-

Maintains stability in high-temperature environments (up to 480°C / 900°F) without oxidation or scaling.

3.3 High Temperature & Pressure Stability

At elevated temperatures (up to 480°C), it retains over 80% of its room-temperature tensile strength—ideal for applications like oil and gas wellheads or chemical reactor shafts that operate under high heat and pressure.

3.4 Excellent Machinability & Formability

While harder than Monel 400, Monel K500 round bar can be machined into complex shapes using carbide tools (with proper cooling). It also supports hot forming (e.g., forging, extrusion) before final precipitation hardening, enabling customization of large components.

4. Industry Standards & Certifications

To ensure quality and consistency, Monel K500 round bar is manufactured and tested to globally recognized standards:

|

Standard Organization |

Standard Number |

Scope |

|---|---|---|

|

ASTM International |

ASTM B865 |

Specification for nickel-copper-aluminum alloy (Monel K500) bar, rod, and wire |

|

ASME |

ASME SB-865 |

Boiler and pressure vessel code-compliant version of ASTM B865 |

|

EN (European Norm) |

EN 1774 |

Nickel and nickel alloy bars, rods, and wires for industrial use |

|

ISO |

ISO 6208 |

Nickel and nickel alloy bars and rods |

|

NACE International |

NACE MR0175/ISO 15156 |

Corrosion-resistant alloys for oil and gas production environments |

Common certifications include Mill Test Reports (MTRs) (per EN 10204 3.1B), NACE MR0175 compliance, and ASTM B865 qualification—critical for industries with strict quality requirements (e.g., aerospace, nuclear).

5. Typical Applications

Monel K500 round bar’s high hardness, anti-oxidation, and corrosion resistance make it suitable for “fail-safe” components across industries:

5.1 Oil & Gas Industry

-

Valve Stems & Seats: Resists corrosion from crude oil, natural gas, and drilling fluids; withstands high pressure (up to 10,000 psi) and temperature fluctuations.

-

Sucker Rods & Pump Shafts: Withstands abrasion from sand and sediment in wellbores; avoids SCC in sour gas (H₂S-containing) environments.

5.2 Marine Engineering

-

Propeller Shafts & Rudder Pins: Resists seawater corrosion and biofouling (e.g., barnacles); maintains strength in saltwater atmospheres.

-

Subsea Connector Components: Operates reliably in deep-sea environments (up to 3,000 meters) without degradation.

5.3 Chemical & Petrochemical Processing

-

Reactor Shafts & Agitator Shafts: Withstands corrosion from acids, alkalis, and solvents; retains strength at high process temperatures (up to 480°C).

-

Heat Exchanger Tubesheets: Resists scaling and oxidation in high-temperature heat transfer fluids.

5.4 Aerospace & Defense

-

Landing Gear Components: Combines high strength and corrosion resistance for aircraft landing gear pins and shafts.

-

Missile Guidance System Parts: Maintains dimensional stability in extreme temperature ranges (-50°C to 400°C).

5.5 Other Critical Engineering

-

Nuclear Power Plant Fasteners: Resists radiation-induced embrittlement and corrosion in coolant systems.

-

Medical Equipment (Surgical Tools): Biocompatible and corrosion-resistant to sterilization fluids (e.g., autoclaves).

6. Other Monel K500 Product Forms

Beyond round bars, Monel K500 is available in various forms to meet diverse application needs:

|

Product Form |

Description & Key Uses |

|---|---|

|

Sheet & Plate |

Thickness: 0.5 mm – 50 mm; used for pressure vessel walls, marine hull plates, and heat exchanger casings. |

|

Pipe & Tube |

OD: 6 mm – 200 mm; used for subsea pipelines, chemical transport lines, and boiler tubes. |

|

Wire |

Diameter: 0.1 mm – 10 mm; used for springs, electrical connectors, and surgical sutures. |

|

Forgings |

Custom-shaped components (e.g., valve bodies, pump impellers) for high-stress applications. |

|

Fasteners |

Bolts, nuts, and screws (per ASTM B865); used in oil rigs, marine structures, and aerospace. |

|

Fittings |

Elbows, tees, and flanges; compatible with Monel K500 pipes for corrosion-resistant piping systems. |

All these forms share the same core properties (high hardness, anti-oxidation, corrosion resistance) as Monel K500 round bar, ensuring consistency across integrated engineering systems.

7. Conclusion

Industrial-grade Monel K500 round bar stands out as a top-tier material for valve stems, shafts, and critical engineering components, where failure is not an option. Its unique blend of precipitation-hardened strength, superior corrosion resistance, and high-temperature stability makes it indispensable in harsh environments—from deep-sea oil fields to aerospace propulsion systems. Backed by global standards and available in multiple product forms, Monel K500 remains a trusted choice for engineers seeking long-lasting, high-performance solutions.

![]()

![]()

![]()

![]()