Όλα τα Προϊόντα

-

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

Raian IonescuΥλική ποιότητα πολύ υψηλή. πρέπει να συνεργαστούμε περισσότερο από 10 έτη. Ανταλλάσσουν τα είδη μερών υλικού χάλυβα. Όλο το υλικό ποιοτικό αγαθό. Αυτοί δασμός για όλη την υλική ποιότητα. Πλανίζουμε συνεχιζόμαστε συνεργαζόμαστε με τους στο μέλλον

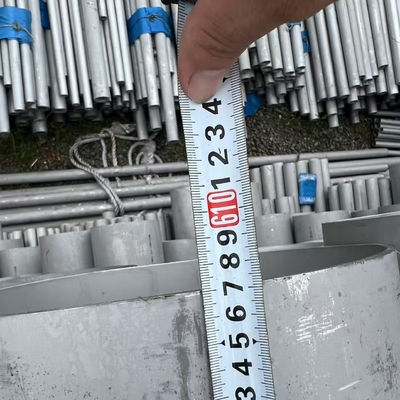

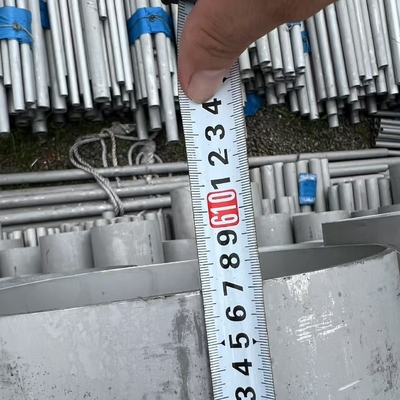

Σωλήνας από ανοξείδωτο χάλυβα ASTM A312 TP310S, ανθεκτικός στη θερμότητα, SS, κράμα 1.4845, SCH40S

| Τόπος καταγωγής | Κίνα |

|---|---|

| Μάρκα | DELTA |

| Πιστοποίηση | ISO |

| Αριθμό μοντέλου | TP310S/1,4845 |

| Ποσότητα παραγγελίας min | 1000 κιλά |

| Τιμή | 6 - 8 USD/Kg |

| Συσκευασία λεπτομέρειες | τυπική συσκευασία για εξαγωγή |

| Χρόνος παράδοσης | 5 - 12 ημέρες με βάση την ποσότητα |

| Όροι πληρωμής | L/C, T/T, Western Union |

| Δυνατότητα προσφοράς | 4 τόνοι την εβδομάδα |

Λεπτομέρειες

| Προϊόντα | Σωλήνας από ανοξείδωτο χάλυβα | Βαθμός | TP310S/1,4845 |

|---|---|---|---|

| Διάμετρος | DN10 - DN400 | Μήκος | 6m ή προσαρμοσμένη κοπή οποιουδήποτε μήκους ως αίτημα |

| Πρότυπο | Astm en | Υπηρεσία | Τομή |

| Θύρα φόρτωσης | Λιμάνι της Σαγκάης | Πάχος | 4.0 - 50.0mm |

| Επισημαίνω | Σωλήνας από ανοξείδωτο χάλυβα ASTM A312 TP310S,Σωλήνας SS ανθεκτικός στη θερμότητα SCH40S,Σωλήνας από ανοξείδωτο χάλυβα κράμα 1.4845 |

||

Περιγραφή προϊόντων

ASTM A312 TP310S ανοξείδωτος σωλήνας σωλήνα σωλήνα θερμότητα Reesistant SS Pipe Roloy 1.4845 SCH40S

Προδιαγραφή προϊόντων

| Όνομα προϊόντων | TP310S ανοξείδωτος σωλήνας |

Βαθμός: |

304 304L 304LN 304H 309S 310S 314 315 316L 316TI 317L 321 329 347H 410 2205 2507 2550 S32760 904L 254SMO και ίσος βαθμός στο GB JIS EN DIN Standard |

| Πρότυπα: | ASTM A213M-94B ASTM A249M-94A ASTM A269-94A ASTM A312M-94B, ECT. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ECT | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994, ECT. | |

| GB13296-1991 GB14975-2002 GB14976-2002, ECT. | |

| Μέγεθος: | ND5 - DN400 |

| Μήκος: | Μήκος 6m ή κοπή οποιουδήποτε μήκους ως αίτημα |

| Εφαρμογές: | Μεταφορά υγρού και αερίου, δομή, λέβητα, εναλλάκτης θερμότητας, σούπερ θερμαντήρας |

ASTM A312 TP310S ανοξείδωτος σωλήνας σωλήνα σωλήνα ανθεκτικό σε κράμα σωλήνα SS 1.4845 SCH40S

Το ASTM A312 TP310S ανοξείδωτο χάλυβα (που επίσης ορίζεται ως κράμα 1.4845 και παρέχεται συνήθως σε πάχος τοίχου SCH40S) είναι ένα premium ανθεκτικό στη θερμότητα Austenitic ανοξείδωτο χάλυβα προϊόν που κατασκευάστηκε για υψηλής θερμοκρασίας και διαβρωτικό βιομηχανικό περιβάλλον. Η μοναδική χημική σύνθεση και οι μηχανικές ιδιότητες του καθιστούν μια προτιμώμενη επιλογή για εφαρμογές που απαιτούν μακροχρόνια σταθερότητα κάτω από ακραία θερμική τάση. Παρακάτω είναι μια ολοκληρωμένη επισκόπηση των παραμέτρων, των προτύπων, των προδιαγραφών, των χαρακτηριστικών, των ισοδύναμων βαθμών και των τυπικών εφαρμογών.

1. Χημική σύνθεση πυρήνα (βάρος %)

Η χημική μακιγιάζ του TP310S ρυθμίζεται αυστηρά για να εξασφαλίσει την αντοχή στη θερμότητα και την απόδοση της διάβρωσης, όπως ορίζεται από τα πρότυπα ASTM:

| Στοιχείο | Ελάχιστο (%) | Μέγιστο (%) | Βασική λειτουργία |

|---|---|---|---|

| Άνθρακας (γ) | - | 0,08 | Μειώνει τις βροχοπτώσεις καρβιδίου σε υψηλές θερμοκρασίες, αποτρέποντας τη διαμεσολαβητική διάβρωση |

| Χρωμίου (CR) | 24.0 | 26.0 | Σχηματίζει ένα πυκνό στρώμα οξειδίου (CR₂O₃) για αντίσταση οξείδωσης σε θερμοκρασίες μέχρι 1150 ° C (2102 ° F) |

| Νικέλιο (Ni) | 19.0 | 22.0 | Σταθεροποιεί την ωστενιτική δομή, ενισχύοντας την ολκιμότητα και την αντίσταση στη θερμική κόπωση |

| Μαγγάνιο (MN) | - | 2.0 | Βελτιώνει τη δυνατότητα λειτουργίας χωρίς να διακυβεύεται η αντίσταση στη θερμότητα |

| Πυρίτιο (SI) | - | 1.5 | Βοηθήματα στον σχηματισμό στρώματος οξειδίου και ενισχύει την αντοχή υψηλής θερμοκρασίας |

| Φωσφόρος (Ρ) | - | 0,045 | Ελεγχόμενη για να ελαχιστοποιήσει τη ευγένεια και τη διατήρηση της συγκολλητικότητας |

| Θείο (ες) | - | 0,030 | Μειωμένη για την πρόληψη καυτών ρωγμών κατά τη διάρκεια της κατασκευής |

| Σίδερο (Fe) | Ισορροπία | - | Βασικό μέταλλο που παρέχει δομική ακεραιότητα |

2. Πρότυπο συμμόρφωσης: ASTM A312

Αυτός ο σωλήνας ακολουθεί αυστηρά το ASTM A312, ένα ευρέως αναγνωρισμένο αμερικανικό πρότυπο για απρόσκοπτα και συγκολλημένους ωστενιτικούς σωλήνες από ανοξείδωτο χάλυβα που προορίζονται για υπηρεσία υψηλής πίεσης και υψηλής θερμοκρασίας. Οι βασικές απαιτήσεις του ASTM A312 περιλαμβάνουν:

- Ομοιόμορφη χημική σύνθεση σε όλο το μήκος του σωλήνα.

- Αυστηρή δοκιμή μηχανικής ιδιοκτησίας (εφελκυσμός, επιμήκυνση).

- Επιλογές μη καταστρεπτικών δοκιμών (NDT): υδροστατικές δοκιμές (υποχρεωτική) για την επαλήθευση της στεγανότητας διαρροής. Προαιρετικές δοκιμές υπερηχητικών (UT) ή ρεύματος Eddy (ECT) για ανίχνευση ελαττωμάτων.

- Έλεγχος ποιότητας συγκόλλησης (για συγκολλημένους σωλήνες) για να εξασφαλιστεί εσωτερικές/εξωτερικές ρωγμές ή πορώδες.

3. Φυσικές και μηχανικές ιδιότητες

Το TP310S παρουσιάζει εξαιρετική μηχανική σταθερότητα τόσο σε περιβάλλοντος όσο και σε αυξημένες θερμοκρασίες:

| Ιδιοκτησία | Προσδιορισμός | Κατάσταση δοκιμής |

|---|---|---|

| Πυκνότητα | 8.0 g/cm3 | Θερμοκρασία περιβάλλοντος |

| Σημείο τήξης | 1400-1450 ° C (2552-2642 ° F) | - |

| Αντοχή εφελκυσμού (ελάχιστο) | 515 MPa (74.700 psi) | Θερμοκρασία δωματίου |

| Αντοχή απόδοσης (0,2% μετατόπιση, ελάχιστο) | 205 MPa (29.700 psi) | Θερμοκρασία δωματίου |

| Επιμήκυνση (ελάχιστο) | 35% | Θερμοκρασία δωματίου (μήκος μετρητή 50 mm) |

| Θερμική αγωγιμότητα | 14.2 W/(m · k) | Στους 100 ° C (212 ° F) |

| Συντελεστής θερμικής διαστολής | 16,0 × 10⁻⁶/° C | 20-100 ° C (68-212 ° F) |

| Μέγιστη θερμοκρασία υπηρεσίας | 1150 ° C (2102 ° F) | Συνεχής χρήση (οξειδωτικά περιβάλλοντα) |

4. Προδιαγραφές προϊόντων (Sch40s & Dimensions)

Η ονομασία "Sch40s" αναφέρεται στο πρότυπο πάχος τοιχώματος για σωλήνες από ανοξείδωτο χάλυβα, που έχει σχεδιαστεί για να εξισορροπεί την αντοχή στην πίεση και την απόδοση βάρους. Οι συνήθεις διαστασιολογικές περιοχές για τους σωλήνες ASTM A312 TP310S SCH40S περιλαμβάνουν:

| Παράμετρος | Σειρά | Σημειώσεις |

|---|---|---|

| Εξωτερική διάμετρος (OD) | 1/2 " - 24" (12,7 mm - 609,6 mm) | Συμμορφώνεται με το ANSI/ASME B36.19 (Διαστάσεις σωλήνων από ανοξείδωτο χάλυβα) |

| Πάχος τοίχου (Sch40s) | 3,91 mm (για 2 "OD) - 11,91 mm (για 10" OD) | Το πάχος ποικίλλει ανάλογα με το OD. Οι ακριβείς τιμές ακολουθούν το B36.19 |

| Μήκος | 6 μέτρα (20 πόδια) - 12 μέτρα (40 πόδια) | Τα πρότυπα μήκη μύλων. Προσαρμοσμένα μήκη διαθέσιμα κατόπιν αιτήματος |

| Μορφή | Απρόσκοπτη ή συγκολλημένη (ERW/SAW) | Απρόσκοπτες σωλήνες για εφαρμογές υψηλής πίεσης. Συγκολλημένο για ανάγκες χαμηλότερης πίεσης, μεγάλης διαμέτρου |

| Φινίρισμα επιφάνειας | 2b (ψυχρό, ομαλή), αρ. 4 (βουρτσισμένο), ή μαυρισμένο και παθητικοποιημένο | Το φινίρισμα τουρσί είναι κοινό για την αντίσταση στη διάβρωση. 2b για εφαρμογές υγιεινής ή αισθητικής |

5. Βασικά χαρακτηριστικά

Ο σωλήνας από ανοξείδωτο χάλυβα TP310S ξεχωρίζει για τον συνδυασμό της αντοχής στη θερμότητα, της απόδοσης και της λειτουργικότητας της διάβρωσης:

- Εξαιρετική αντοχή στη θερμότητα: Διατηρεί τη δομική ακεραιότητα σε συνεχή υπηρεσία έως 1150 ° C (2102 ° F) και διαλείπουσα υπηρεσία έως 1200 ° C (2192 ° F), καθιστώντας την πολύ πιο ανεκτική από τη θερμότητα από τους κοινούς βαθμούς όπως 304 ή 316.

- Ανώτερη αντοχή στη διάβρωση: Αντιστέκεται η οξείδωση, η σουλφιδίωση και η καρμπουργία σε περιβάλλοντα υψηλής θερμοκρασίας (π.χ., καυσαέρια καυσαερίων, ατμός). Προσφέρει επίσης καλή αντίσταση σε ήπια οξέα (π.χ. αραιωμένο θειικό οξύ) και αλμυρό νερό.

- Εξαιρετική ολκιμότητα & συγκολλητικότητα: Μπορεί εύκολα να συγκολληθεί χρησιμοποιώντας τυπικές μεθόδους (TIG, MIG, SMAW) χωρίς να χάσει μηχανικές ιδιότητες. Ο υψηλός ρυθμός επιμήκυνσης (≥35%) επιτρέπει την κάμψη, τη διαμόρφωση και την κατασκευή σε σύνθετα σχήματα.

- Χαμηλής περιεκτικότητας σε άνθρακα: Η μέγιστη κατάργηση του άνθρακα 0,08% περιορίζει τις βροχοπτώσεις καρβιδίου στα όρια των κόκκων (κοινή αιτία ρωγμών σε υπηρεσία υψηλής θερμοκρασίας), εξασφαλίζοντας μακροπρόθεσμη αξιοπιστία.

6. Ισοδύναμοι βαθμοί

Το TP310S είναι γνωστό με διαφορετικές ονομασίες παγκοσμίως, ανάλογα με τα περιφερειακά πρότυπα. Παρακάτω είναι μια λίστα βασικών ισοδύναμων βαθμών για διασταύρωση:

| Πρότυπο | Ονομασία βαθμού | Περιοχή |

|---|---|---|

| ASTM/ASME | TP310s | Βόρεια Αμερική |

| EN 10216-5 | 1.4845 | Ευρώπη |

| JIS G3463 | SUS310S | Ιαπωνία |

| GB/T 14976 | 06CR25NI20 | Κίνα |

| Ανυψωμένος | S31008 | Διεθνές (ενοποιημένο σύστημα αρίθμησης) |

Σημείωση: Ενώ οι βαθμοί αυτοί είναι χημικά και μηχανικά παρόμοιες, μπορεί να υπάρχουν μικρές παραλλαγές σε 微量元素 (στοιχεία ιχνοστοιχείων) ή απαιτήσεις δοκιμών. Πάντα επιβεβαιώστε τη συμβατότητα με συγκεκριμένα πρότυπα εφαρμογών.

7. Τυπικές εφαρμογές

Λόγω της αντοχής της θερμότητας και της απόδοσης της διάβρωσης, ο σωλήνας SCH40S ASTM A312 TP310S χρησιμοποιείται ευρέως σε βιομηχανικούς τομείς υψηλής θερμοκρασίας:

- Εξοπλισμός θερμικής επεξεργασίας: Σωλήνες κλιβάνου, ακτινοβολημένοι σωλήνες και στοιχεία θέρμανσης για βιομηχανικούς κλιβάνους (π.χ. ανόπτηση, σκούδια σκλήρυνσης).

- Παραγωγή ενέργειας: σωλήνες λέβητα, σωλήνες υπερθερμαντήρα και αγωγοί ατμού σε μονάδες παραγωγής ηλεκτρικής ενέργειας με καύση άνθρακα, αέριο ή απόβλητα προς ενέργεια.

- Petrochemical & ραφιναρίσματος: σωλήνες για καταλυτικά κροτίδες, μεταρρυθμιστές και συστήματα εξάτμισης (αντιστέκεται στη σουλφιδίωση από την επεξεργασία αργού πετρελαίου).

- Μεταλλουργική βιομηχανία: Σωλήνες για εξάτμιση χαλύβδινου μύλου, γραμμές μεταφοράς τετηγμένου μετάλλου και φυτά πυροσυσσωμάτωσης.

- Άλλες χρήσεις υψηλής θερμοκρασίας: καμινάδες αποτεφρωτήρα, θερμικές οξειδωτές και εξοπλισμός επεξεργασίας τροφίμων (όπου η αντίσταση θερμότητας και διάβρωσης είναι κρίσιμη).

![]()

![]()

![]()

![]()

Συνιστώμενα προϊόντα