Tous les produits

-

Bande d'acier inoxydable

-

Feuille d'acier inoxydable

-

Plaque d'acier inoxydable

-

tuyau d'acier inoxydable

-

Barre d'acier inoxydable

-

Bobine en acier galvanisée

-

Plaque d'acier

-

barre ronde en acier

-

alliage de nickel

-

Tuyau d'acier sans couture

-

Poutre d'acier inoxydable

-

Feuille de plat de cuivre

-

Barre ronde de cuivre

-

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

Raian IonescuQualité matérielle très bonne. nous avons pour coopérer plus de 10 ans. Ils commercent des genres de sorts de matériel en acier. Toute la qualité matérielle bonne. Ils devoir pour toute la qualité matérielle. Nous surfaçons pour continuer à coopérer avec eux à l'avenir

ASTM A312 TP310S Tubes en acier inoxydable résistantes à la chaleur SS Pipe Alloy 1.4845 SCH40S

| Lieu d'origine | Chine |

|---|---|

| Nom de marque | DELTA |

| Certification | ISO |

| Numéro de modèle | TP310S/1,4845 |

| Quantité de commande min | 1000 kg |

| Prix | 6 - 8 USD/Kg |

| Détails d'emballage | Emballage standard pour l'exportation |

| Délai de livraison | 5 - 12 jours en fonction de la quantité |

| Conditions de paiement | L / C, T / T, Western Union |

| Capacité d'approvisionnement | 4 tonnes par semaine |

Détails sur le produit

| Produits | Tuyau sans couture en acier inoxydable | Grade | TP310S/1,4845 |

|---|---|---|---|

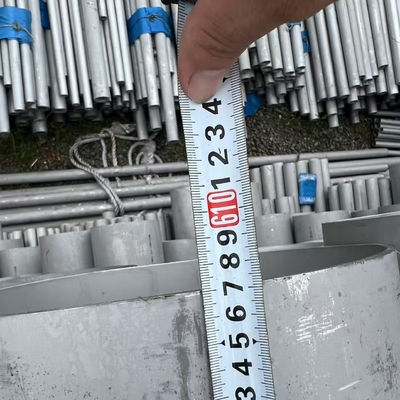

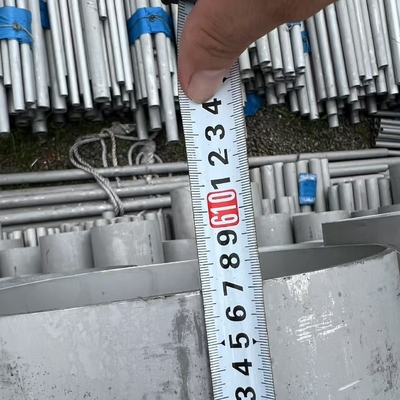

| Diamètre | DN10 - DN400 | Longueur | 6m ou courir personnalisé n'importe quelle longueur comme demande |

| Standard | Astm en | Service | Coupe |

| Port de chargement | Port de Shanghai | Épaisseur | 4,0 - 50,0 mm |

| Mettre en évidence | Pièces en acier inoxydable ASTM A312 TP310S,tuyau SS résistant à la chaleur SCH40S,alliage de tubes en acier inoxydable 1.4845 |

||

Description de produit

ASTM A312 TP310S Tube de tuyau en acier inoxydable Résistant à la chaleur Tuyau SS Alliage 1.4845 SCH40S

Spécifications des produits

| Nom des produits | Tube sans soudure en acier inoxydable TP310S |

Qualité : |

304 304L 304LN 304H 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 2550 S32760 904L 254SMO et qualité équivalente dans les normes GB JIS EN DIN |

| Normes : | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Taille : | ND5 - DN400 |

| Longueur : | Longueur de 6 m ou coupe de n'importe quelle longueur sur demande |

| Applications : | transport de fluides et de gaz, structure, chaudière, échangeur de chaleur, surchauffeur |

ASTM A312 TP310S Tube de tuyau en acier inoxydable résistant à la chaleur Tuyau SS Alliage 1.4845 SCH40S

Le tube en acier inoxydable ASTM A312 TP310S (également désigné sous le nom d'alliage 1.4845 et généralement fourni avec une épaisseur de paroi SCH40S) est un produit en acier inoxydable austénitique résistant à la chaleur de qualité supérieure, conçu pour les environnements industriels à haute température et corrosifs. Sa composition chimique et ses propriétés mécaniques uniques en font un choix privilégié pour les applications nécessitant une stabilité à long terme sous des contraintes thermiques extrêmes. Vous trouverez ci-dessous un aperçu complet de ses paramètres, normes, spécifications, caractéristiques, qualités équivalentes et applications typiques.

1. Composition chimique de base (en poids %)

La composition chimique du TP310S est strictement réglementée pour garantir la résistance à la chaleur et la performance à la corrosion, comme défini par les normes ASTM :

| Élément | Minimum (%) | Maximum (%) | Fonction clé |

|---|---|---|---|

| Carbone (C) | - | 0,08 | Réduit la précipitation de carbures à haute température, empêchant la corrosion intergranulaire |

| Chrome (Cr) | 24,0 | 26,0 | Forme une couche d'oxyde dense (Cr₂O₃) pour la résistance à l'oxydation à des températures allant jusqu'à 1150 °C (2102 °F) |

| Nickel (Ni) | 19,0 | 22,0 | Stabilise la structure austénitique, améliorant la ductilité et la résistance à la fatigue thermique |

| Manganèse (Mn) | - | 2,0 | Améliore l'usinabilité sans compromettre la résistance à la chaleur |

| Silicium (Si) | - | 1,5 | Facilite la formation de la couche d'oxyde et améliore la résistance à haute température |

| Phosphore (P) | - | 0,045 | Contrôlé pour minimiser la fragilité et maintenir la soudabilité |

| Soufre (S) | - | 0,030 | Réduit pour éviter le criquage à chaud pendant la fabrication |

| Fer (Fe) | Équilibre | - | Métal de base assurant l'intégrité structurelle |

2. Conformité à la norme : ASTM A312

Ce tube est strictement conforme à la norme ASTM A312, une norme américaine largement reconnue pour les tubes en acier inoxydable austénitique sans soudure et soudés destinés aux services à haute pression et à haute température. Les principales exigences de la norme ASTM A312 comprennent :

- Composition chimique uniforme sur toute la longueur du tube.

- Essais rigoureux des propriétés mécaniques (traction, allongement).

- Options d'essais non destructifs (END) : Essai hydrostatique (obligatoire) pour vérifier l'étanchéité ; essais par ultrasons (UT) ou par courants de Foucault (ECT) facultatifs pour la détection des défauts.

- Contrôle de la qualité des soudures (pour les tubes soudés) pour garantir l'absence de fissures ou de porosité internes/externes.

3. Propriétés physiques et mécaniques

Le TP310S présente une excellente stabilité mécanique à la fois à température ambiante et à température élevée :

| Propriété | Spécification | Condition d'essai |

|---|---|---|

| Densité | 8,0 g/cm³ | Température ambiante |

| Point de fusion | 1400–1450 °C (2552–2642 °F) | - |

| Résistance à la traction (minimum) | 515 MPa (74 700 psi) | Température ambiante |

| Limite d'élasticité (0,2 % de décalage, minimum) | 205 MPa (29 700 psi) | Température ambiante |

| Allongement (minimum) | 35 % | Température ambiante (longueur de jauge de 50 mm) |

| Conductivité thermique | 14,2 W/(m·K) | À 100 °C (212 °F) |

| Coefficient de dilatation thermique | 16,0 × 10⁻⁶/°C | 20–100 °C (68–212 °F) |

| Température de service maximale | 1150 °C (2102 °F) | Utilisation continue (environnements oxydants) |

4. Spécifications du produit (SCH40S et dimensions)

La désignation « SCH40S » fait référence à l'épaisseur de paroi standard des tubes en acier inoxydable, conçue pour équilibrer la résistance à la pression et l'efficacité du poids. Les plages dimensionnelles courantes pour les tubes ASTM A312 TP310S SCH40S comprennent :

| Paramètre | Plage | Remarques |

|---|---|---|

| Diamètre extérieur (OD) | 1/2 » – 24 » (12,7 mm – 609,6 mm) | Conforme à la norme ANSI/ASME B36.19 (dimensions des tubes en acier inoxydable) |

| Épaisseur de paroi (SCH40S) | 3,91 mm (pour OD 2 ») – 11,91 mm (pour OD 10 ») | L'épaisseur varie avec l'OD ; les valeurs exactes suivent B36.19 |

| Longueur | 6 mètres (20 pi) – 12 mètres (40 pi) | Longueurs standard des usines ; longueurs personnalisées disponibles sur demande |

| Forme | Sans soudure ou soudé (ERW/SAW) | Tubes sans soudure pour les applications à haute pression ; soudés pour les besoins à basse pression et de grand diamètre |

| Finition de surface | 2B (laminé à froid, lisse), n° 4 (brossé) ou décapé et passivé | La finition décapée est courante pour la résistance à la corrosion ; 2B pour les applications sanitaires ou esthétiques |

5. Caractéristiques principales

Le tube en acier inoxydable TP310S se distingue par sa combinaison de résistance à la chaleur, de performance à la corrosion et d'usinabilité :

- Résistance à la chaleur exceptionnelle : maintient l'intégrité structurelle en service continu jusqu'à 1150 °C (2102 °F) et en service intermittent jusqu'à 1200 °C (2192 °F), ce qui le rend beaucoup plus tolérant à la chaleur que les qualités courantes comme 304 ou 316.

- Résistance supérieure à la corrosion : résiste à l'oxydation, à la sulfuration et à la carburation dans les environnements à haute température (par exemple, les gaz de carneau de four, la vapeur). Offre également une bonne résistance aux acides faibles (par exemple, l'acide sulfurique dilué) et à l'eau salée.

- Excellente ductilité et soudabilité : peut être facilement soudé à l'aide de méthodes standard (TIG, MIG, SMAW) sans perdre ses propriétés mécaniques. Son taux d'allongement élevé (≥ 35 %) permet le pliage, le formage et la fabrication en formes complexes.

- Faible teneur en carbone : le carbone maximum de 0,08 % limite la précipitation de carbures aux joints de grains (une cause fréquente de fissuration en service à haute température), assurant une fiabilité à long terme.

6. Qualités équivalentes

Le TP310S est connu sous différentes désignations dans le monde, en fonction des normes régionales. Vous trouverez ci-dessous une liste des principales qualités équivalentes pour référence croisée :

| Norme | Désignation de la qualité | Région |

|---|---|---|

| ASTM/ASME | TP310S | Amérique du Nord |

| EN 10216-5 | 1.4845 | Europe |

| JIS G3463 | SUS310S | Japon |

| GB/T 14976 | 06Cr25Ni20 | Chine |

| UNS | S31008 | International (Unified Numbering System) |

Remarque : Bien que ces qualités soient chimiquement et mécaniquement similaires, des variations mineures peuvent exister dans les 微量元素 (oligo-éléments) ou les exigences d'essai. Confirmez toujours la compatibilité avec les normes d'application spécifiques.

7. Applications typiques

En raison de sa résistance à la chaleur et de sa performance à la corrosion, le tube ASTM A312 TP310S SCH40S est largement utilisé dans les secteurs industriels à haute température :

- Équipement de traitement thermique : tubes de four, tubes radiants et éléments chauffants pour fours industriels (par exemple, fours de recuit, de durcissement).

- Production d'énergie : tubes de chaudière, tubes de surchauffeur et pipelines de vapeur dans les centrales au charbon, au gaz ou de valorisation énergétique.

- Pétrochimie et raffinage : tubes pour craqueurs catalytiques, reformeurs et systèmes d'échappement (résiste à la sulfuration du traitement du pétrole brut).

- Industrie métallurgique : tubes pour les échappements des aciéries, les conduites de transfert de métal en fusion et les usines de frittage.

- Autres utilisations à haute température : cheminées d'incinérateur, oxydants thermiques et équipements de transformation des aliments (où la résistance à la chaleur et à la corrosion sont essentielles).

![]()

![]()

![]()

![]()

produits recommandés