-

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

Raian IonescuMaterielle Qualität sehr gut. wir haben, zusammenzuarbeiten mehr als 10 Jahre. Sie handeln Losarten des Stahlmaterials. Alle materielle Qualitätsware. Sie Aufgabe für alle materielle Qualität. Wir planieren fortzufahren, mit ihnen in der Zukunft zusammenzuarbeiten

2000mm Width 304 / 304L Stainless Steel Plate Thickness 3.0 - 40.0mm Thickness SS Plate for Industrial

| Herkunftsort | China |

|---|---|

| Markenname | DELTA |

| Zertifizierung | ISO |

| Modellnummer | 304 / 304L |

| Min Bestellmenge | 500 kg |

| Preis | 2000-2400 USD/Ton |

| Verpackung Informationen | Holzpaletten + wasserdichtes Papier |

| Lieferzeit | 5 - 12 Tage je nach Menge |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Versorgungsmaterial-Fähigkeit | 5Ton pro Woche |

Treten Sie mit mir für freie Proben und Kupons in Verbindung.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Wenn Sie irgendein Interesse haben, leisten wir 24-stündige Online-Hilfe.

x| Produkte | Edelstahlplatte | Grad | 304 304l |

|---|---|---|---|

| Standardgröße | 2000*6000mm | Dicke | 3.0 - 40.0mm |

| Marke | TISCO BAOSTEEL POSCO LISCO | Ladehafen | Hafen von Shanghai |

| Mindestbestellmenge | 500 kg | Verpackung | Holzpaletten + wasserdichtes Papier |

2000mm Width 304 / 304L Stainless Steel Plate Thickness 3.0 - 40.0mm Thickness SS Plate for Industrial

Products Specification

| Products | Stainless Steel Plate |

| Thickness | 0.4 - 40.0mm |

| Width | 1000mm 1219mm 1500mm 1800mm 2000mm or other width as request |

| Length | 2000mm 2438mm 3000mm 6000mm or other length as request |

| Grade | 201 202 301 304 304L 304H 309S 310S 316L 316Ti 317L 321 347 409L 410 420 430 431 436L 439 441 443 444 2205 2507 904L 600 625 800 825 718 253MA 254SMO.etc |

| Service | Laser Cutting, Surface processing, bending |

| Brand | TISCO BAOSTEEL POSCO LISCO JISCO |

| Standard | ASTM JIS GB DIN EN BS |

| Certificate | ISO MTC C/O F/E |

| Packing | Wooden pallets and waterproof paper |

| Deliver time | 5 - 15 days |

| Loading port | Shanghai Port |

Overview

Key Advantages of 2000mm Wide 304/304L Plates

- Wide Format Efficiency: The 2000mm (≈78.7 inches) width minimizes the need for seam welding in large fabrications, reducing labor costs and improving structural integrity.

- Broad Thickness Range: From thin 3.0mm sheets for cladding and ductwork to robust 40.0mm plates for pressure vessels and structural supports.

- Superior Corrosion Resistance: Excellent performance in oxidizing environments, mild acids, alkalis, and atmospheric exposure.

- Weldability & Formability: Both grades are readily weldable by all standard methods; 304L is preferred for heavy-section welding.

- Cryogenic Toughness: Maintains ductility and impact strength at temperatures as low as -196°C (liquid nitrogen), making it ideal for LNG and cryogenic transport systems.

- Hygienic Surface Options: Available in finishes like 2B, No.1, BA, No.4 (brushed), and custom textures for sanitary or aesthetic applications.

Technical Specifications

| Parameter | Details |

|---|---|

| Material Grades | AISI 304 (S30400), AISI 304L (S30403) |

| Width | 2000 mm (standard); custom widths up to 2000 mm available |

| Thickness Range | 3.0 mm – 40.0 mm |

| Length | 1000 mm – 12000 mm (custom cut-to-length available) |

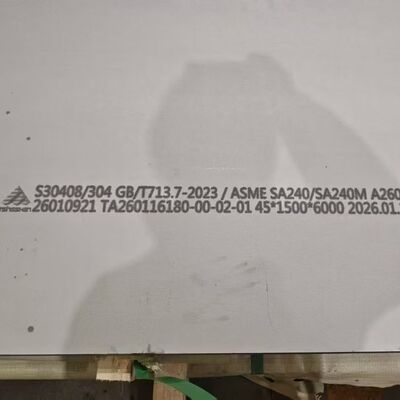

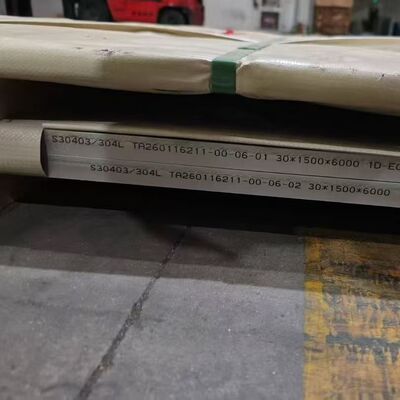

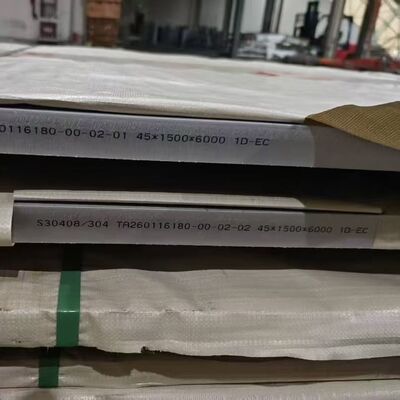

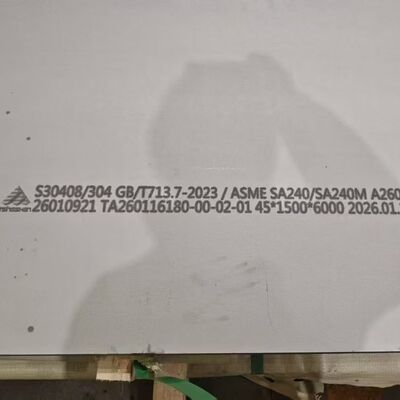

| Standards | ASTM A240/A240M, ASME SA240, GB/T 24511, EN 10088-2, JIS G4304 |

| Surface Finishes | No.1 (hot-rolled, annealed & pickled), 2B (cold-rolled, bright annealed), BA (bright annealed), No.4 (brushed), 8K (mirror), custom textures |

| Tolerances | Thickness: ±0.10 mm (for ≤10mm), ±1% (for >10mm); Width: ±5 mm; Flatness: ≤5 mm/m |

| Mechanical Properties (Typical) | Tensile Strength: ≥515 MPa; Yield Strength (0.2%): ≥205 MPa; Elongation: ≥40%; Hardness: ≤201 HB |

| Chemical Composition (304) | C ≤0.08%, Si ≤1.0%, Mn ≤2.0%, P ≤0.045%, S ≤0.03%, Cr 18–20%, Ni 8–10.5%, N ≤0.10% |

| Chemical Composition (304L) | C ≤0.03%, Si ≤1.0%, Mn ≤2.0%, P ≤0.045%, S ≤0.03%, Cr 18–20%, Ni 8–12%, N ≤0.10% |

| Certifications | Mill Test Certificate (EN 10204 3.1), ISO 9001:2015, PED 2014/68/EU (for pressure equipment), SGS, RoHS compliance upon request |

Applications by Industry

| Industry | Typical Use Cases |

|---|---|

| Chemical & Petrochemical | Reactors, storage tanks, heat exchangers, piping systems |

| Food & Beverage | Processing tanks, conveyors, pasteurizers, hygienic surfaces |

| Pharmaceutical | Cleanroom equipment, sterile vessels, water purification systems |

| Energy & Power | Boiler components, flue gas desulfurization units, turbine parts |

| LNG & Cryogenics | Insulated pipelines, cryogenic valves, storage tanks (304L preferred) |

| Marine & Offshore | Deck fittings, seawater handling systems (with proper passivation) |

| Architecture | Cladding, roofing, decorative panels (brushed or mirror finish) |

| Heavy Machinery | Wear plates, structural frames, hydraulic reservoirs |

Why Choose 2000mm Width?

- Reduced Welding Joints: Fewer seams mean lower fabrication time, reduced risk of leakage, and improved aesthetics.

- Higher Material Utilization: Optimized nesting for laser cutting or plasma profiling reduces scrap.

- Structural Continuity: Ideal for large-diameter rolled cylinders (e.g., pressure vessels) without longitudinal welds.

- Logistical Efficiency: Fewer pieces to handle, ship, and inventory.

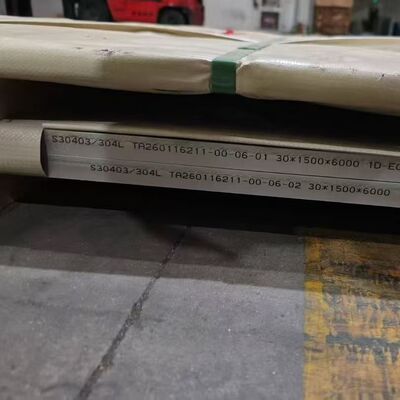

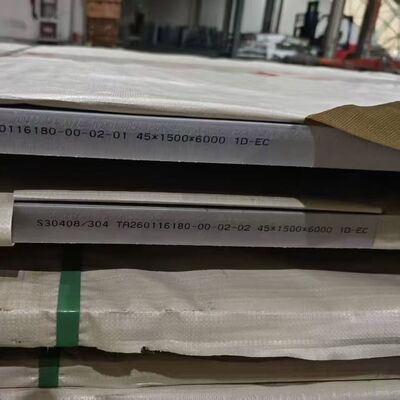

Quality Assurance & Traceability

- Spectrometric analysis for chemical composition

- Ultrasonic testing (UT) for internal defects (optional for critical applications)

- Tensile and hardness testing

- Surface inspection under controlled lighting

- Full traceability via heat number and production log

Packaging & Delivery

- Interleaved with PVC film or paper

- Bundled with steel straps

- Wooden pallets or cradles for thick plates (>20mm)

- Export-standard fumigated wooden cases (upon request)

Frequently Asked Questions (FAQ)

A: 304L has lower carbon content (<0.03% vs. ≤0.08%), which prevents chromium carbide precipitation during welding, thus avoiding intergranular corrosion. Use 304L for welded structures >6mm thick or when post-weld annealing isn’t feasible.

A: Yes. Advanced rolling mills now produce 40mm-thick 304/304L plates at 2000mm width with excellent flatness and uniform properties—ideal for heavy industrial use.

A: Absolutely. 304/304L resists rust in most atmospheric conditions. For coastal or high-chloride environments, consider 316L for enhanced pitting resistance.

A: Yes. We provide precision shearing, laser cutting, and waterjet profiling to your exact dimensions.

Conclusion