ASTM B574 Hastelloy G35 Alloy Plate / Alloy 2.4643 for Chemical Processing Applications

Hastelloy G35, also known as Alloy 2.4643, is a high-performance nickel-based alloy designed specifically for use in chemical processing and other demanding environments where corrosion resistance and mechanical strength are critical. Manufactured in compliance with ASTM B574, this alloy plate is ideal for applications involving exposure to harsh chemical environments, high temperatures, and oxidizing conditions. It is widely used in industries such as chemical processing, power generation, aerospace, and marine engineering.

In this article, we will explore the key features, mechanical properties, chemical composition, and typical applications of Hastelloy G35 alloy plate, along with answers to some frequently asked questions (FAQs). A summary table will also be provided for easy reference.

What is Hastelloy G35?

Hastelloy G35 (Alloy 2.4643) is a nickel-chromium-molybdenum alloy known for its excellent resistance to oxidation, carburization, and a wide range of corrosive environments, especially at elevated temperatures. The alloy is produced following the ASTM B574 standard, which ensures consistency and high quality for critical applications. Due to its composition and properties, Hastelloy G35 is well-suited for environments where other materials might fail due to corrosion or extreme temperature conditions.

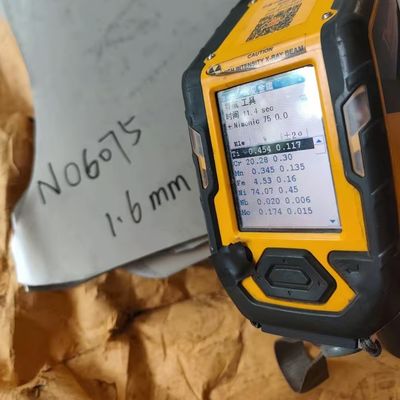

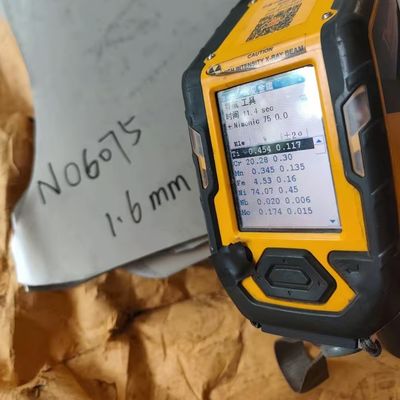

Chemical Composition of Hastelloy G35

Hastelloy G35’s superior corrosion resistance is attributed to its unique blend of elements. Below is the typical chemical composition of Hastelloy G35:

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 50 - 60 |

| Chromium (Cr) | 15 - 25 |

| Molybdenum (Mo) | 5 - 10 |

| Iron (Fe) | 10 - 20 |

| Manganese (Mn) | 1 - 2 |

| Silicon (Si) | 0.5 max |

| Carbon (C) | 0.02 max |

| Phosphorus (P) | 0.03 max |

| Sulfur (S) | 0.03 max |

Composition Highlights:

-

Nickel (Ni): The primary component, offering exceptional resistance to oxidation and corrosion in various aggressive chemical environments.

-

Chromium (Cr): Enhances the alloy’s resistance to oxidation at high temperatures and helps prevent the formation of scale in high-temperature environments.

-

Molybdenum (Mo): Contributes to the alloy’s resistance to pitting and crevice corrosion, particularly in chloride-containing environments.

-

Iron (Fe): Improves mechanical strength and forms a solid base for the alloy’s structure.

-

Manganese (Mn): Adds toughness and helps in improving resistance to hot cracking during welding.

Mechanical Properties of Hastelloy G35

Hastelloy G35 is known for its exceptional mechanical strength, making it an excellent material for use in high-stress and high-temperature environments. Below are the key mechanical properties:

| Property | Value |

|---|---|

| Tensile Strength | 90 ksi (620 MPa) |

| Yield Strength | 35 ksi (240 MPa) |

| Elongation (in 2 inches) | 40% minimum |

| Hardness | 85 HRB (Rockwell B scale) |

| Density | 8.89 g/cm³ |

| Modulus of Elasticity | 207 GPa (30,000 ksi) |

| Thermal Conductivity | 12.5 W/m·K |

| Coefficient of Thermal Expansion | 14.6 x 10⁻⁶/°C |

Mechanical Property Highlights:

-

Tensile Strength: Hastelloy G35 can withstand substantial loads, making it a reliable choice for structural components in aggressive environments.

-

Elongation: With a minimum of 40% elongation, the material has excellent ductility, enabling it to bend without breaking, which is crucial for fabricating complex shapes.

-

Hardness: The alloy’s hardness of 85 HRB ensures resistance to surface wear while maintaining the necessary flexibility for forming and welding.

-

High Modulus of Elasticity: This provides high rigidity, ensuring the alloy performs well under stress without significant deformation.

ASTM B574 Standard

ASTM B574 specifies the requirements for nickel and nickel alloy plate, sheet, and strip, including Hastelloy G35. It covers chemical composition, mechanical properties, dimensions, and surface finish of the material, ensuring that it meets the highest standards of quality and consistency. The standard ensures that the alloy plate is suitable for demanding chemical processing applications, with strict controls over:

-

Chemical composition to ensure uniformity and performance.

-

Mechanical properties to meet application-specific strength and elongation requirements.

-

Dimensional tolerances for manufacturing consistency.

-

Surface finish to ensure that the alloy plate is free from defects that could compromise its integrity in service.

Key Features of Hastelloy G35

1. Superior Corrosion Resistance

Hastelloy G35 exhibits excellent resistance to a wide range of corrosive environments, particularly in chemical processing where exposure to sulfuric acid, hydrochloric acid, and other aggressive chemicals is common. It resists both oxidizing and reducing acids, making it one of the top choices for chemical and petrochemical industries.

2. High-Temperature Performance

The alloy maintains its mechanical properties at elevated temperatures (up to 1800°F or 982°C), making it highly suitable for high-temperature environments such as furnace components, heat exchangers, and reactors in chemical plants.

3. Pitting and Crevice Corrosion Resistance

Hastelloy G35’s resistance to pitting and crevice corrosion, particularly in chloride-rich environments, is one of its strongest attributes. This makes it ideal for use in marine, offshore, and saltwater environments.

4. Weldability

The alloy is highly weldable, which is crucial for applications requiring complex geometries and ease of fabrication. Standard welding techniques such as TIG and MIG are commonly used without compromising the alloy’s properties.

5. Durability and Longevity

Hastelloy G35 provides a long service life even in harsh conditions, reducing the need for frequent replacements or maintenance. This leads to lower overall operating costs for industries that rely on it.

Applications of Hastelloy G35

Hastelloy G35 is widely used in industries where corrosion resistance and high-temperature performance are critical. Some of the key applications include:

1. Chemical Processing

-

Heat exchangers, reactors, and vessels exposed to aggressive chemicals such as sulfuric acid, hydrochloric acid, and chlorides.

-

Pipes and valves in systems that handle corrosive liquids or gases.

-

Distillation columns and evaporators used in chemical manufacturing.

2. Aerospace

-

Gas turbine components that require resistance to high temperatures and oxidation.

-

Combustion chambers and other engine parts exposed to extreme thermal and mechanical stress.

3. Marine Engineering

-

Seawater pumps, heat exchangers, and desalination plants exposed to salty environments.

-

Marine structures exposed to chloride-induced corrosion.

4. Power Generation

-

Boilers, heat exchangers, and combustion chambers that experience high temperatures and corrosive gases.

5. Pharmaceutical and Food Processing

-

Mixing tanks, storage tanks, and filters used in applications requiring resistance to acidic or corrosive substances.

FAQs About Hastelloy G35 Alloy Plate

1. What is the primary advantage of using Hastelloy G35?

The primary advantage of Hastelloy G35 is its outstanding resistance to corrosion, particularly in environments that involve strong acids and high temperatures. It also offers excellent mechanical strength and weldability, making it versatile for a variety of industries.

2. Can Hastelloy G35 be welded?

Yes, Hastelloy G35 is highly weldable. It can be welded using standard methods such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding. Special care must be taken during the welding process to avoid high heat input, which can lead to localized distortion.

3. How does Hastelloy G35 compare to other Hastelloy alloys?

Hastelloy G35 offers better resistance to sulfuric acid and chloride-based corrosion compared to other alloys like Hastelloy C276 or Hastelloy B2. It is optimized for environments where high-temperature and corrosion resistance are essential.

4. What industries benefit from using Hastelloy G35?

Hastelloy G35 is ideal for chemical processing, aerospace, marine engineering, power generation, and food and pharmaceutical processing, where its combination of strength, corrosion resistance, and high-temperature performance provides long-term reliability.

5. Is Hastelloy G35 suitable for seawater applications?

Yes, due to its exceptional resistance to chloride-induced stress corrosion cracking, Hastelloy G35 is an excellent