Alle producten

-

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

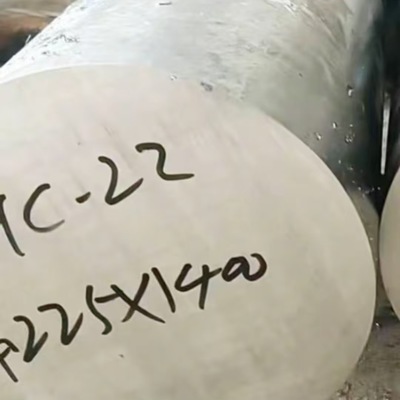

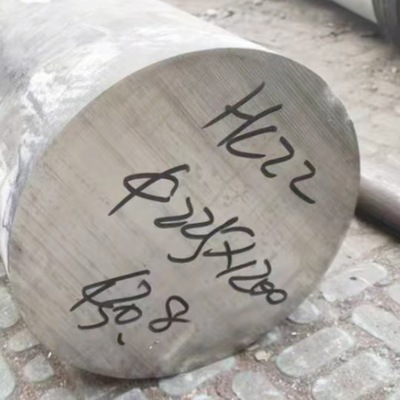

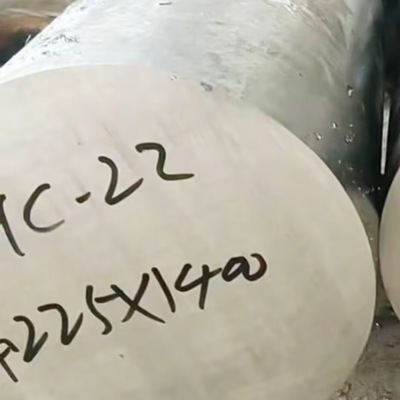

Alloy 2.4602 /Hastelloy C22 / UNS N06022 Nickel Alloy Round Bar With ASTM EN DIN Standard

| Plaats van herkomst | CHINA |

|---|---|

| Merknaam | DELTA |

| Certificering | ISO |

| Modelnummer | Hastelloy c-22 |

| Min. bestelaantal | 10 kg |

| Prijs | 35 - 45 USD/Kg |

| Verpakking Details | Standaardverpakking voor export |

| Levertijd | 5 - 12 dagen op basis van de hoeveelheid |

| Betalingscondities | L/C, T/T, Western Union |

| Levering vermogen | 3 ton per week |

Productdetails

| Producten | Hastelloy C-22 ronde staaf | Cijfer | Hastelloy C22 |

|---|---|---|---|

| Diameter | 10 - 350mm | Lengte | op aanvraag op maat gesneden |

| Standaard | Astm en | Dienst | Snij |

| Laadpoort | Shanghai -haven | Oppervlak | helder, zwart |

| Markeren | Hastelloy C22 nickel alloy round bar,Alloy 2.4602 round bar ASTM standard,UNS N06022 nickel bar DIN standard |

||

Productomschrijving

Alloy 2.4602 /Hastelloy C22 / UNS N06022 Nickel Alloy Round Bar With ASTM EN DIN Standard

More Specification Informations

| Products Name | Hastelloy C22 round bar |

| Diameter | 10 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Alloy 2.4602 /Hastelloy C22 / UNS N06022 Nickel Alloy Round Bar With ASTM EN DIN Standard

1. Product Overview

Hastelloy C22 (Alloy 2.4602 / UNS N06022) nickel alloy round bar is a premium-grade nickel - chromium - molybdenum - tungsten alloy product. It is meticulously manufactured to meet the rigorous requirements of ASTM, EN, and DIN standards, making it highly suitable for applications in harsh industrial environments where excellent corrosion resistance, high - temperature strength, and structural stability are essential. This round bar product is available in a wide range of dimensions to cater to the diverse needs of different industries, from small - diameter bars used in precision components to large - diameter bars for heavy - duty structural parts.

2. Chemical Composition (Typical Values, %)

The precise chemical composition of Hastelloy C22 nickel alloy round bar is a key factor contributing to its outstanding performance. The typical composition is as follows:

- Nickel (Ni): 56.0 - 60.0% (primary matrix element, providing excellent ductility and corrosion resistance)

- Chromium (Cr): 20.0 - 22.5% (enhances oxidation and corrosion resistance, especially in oxidizing environments)

- Molybdenum (Mo): 12.5 - 14.5% (improves resistance to pitting, crevice corrosion, and general corrosion in reducing environments)

- Tungsten (W): 2.5 - 3.5% (enhances high - temperature strength and creep resistance, and also contributes to corrosion resistance)

- Iron (Fe): ≤ 2.0% (trace element, affecting the alloy's mechanical properties and corrosion resistance to a certain extent)

- Cobalt (Co): ≤ 2.5% (trace element, can improve the alloy's high - temperature strength and wear resistance)

- Carbon (C): ≤ 0.015% (low carbon content, reducing the risk of intergranular corrosion)

- Silicon (Si): ≤ 0.08% (trace element, affecting the alloy's casting and welding properties)

- Manganese (Mn): ≤ 0.5% (trace element, can improve the alloy's strength and ductility)

- Phosphorus (P): ≤ 0.02% (harmful impurity, strictly controlled to avoid reducing the alloy's toughness and corrosion resistance)

- Sulfur (S): ≤ 0.01% (harmful impurity, strictly controlled to prevent hot cracking during welding and reduce corrosion resistance)

3. Mechanical Properties

3.1 Room - Temperature Mechanical Properties

- Tensile Strength (σb): ≥ 690 MPa (ensuring the round bar has sufficient strength to withstand external loads in various applications)

- Yield Strength (σ0.2): ≥ 310 MPa (indicating the minimum stress required to cause permanent deformation, ensuring the structural stability of the product)

- Elongation (δ5): ≥ 40% (reflecting the alloy's good ductility, allowing for easy processing such as bending and forming without cracking)

- Hardness (HB): ≤ 230 (indicating a moderate hardness, which is beneficial for machining while maintaining certain wear resistance)

3.2 High - Temperature Mechanical Properties (At 650°C)

- Tensile Strength (σb): ≥ 450 MPa (maintaining high strength at elevated temperatures, suitable for high - temperature working environments)

- Yield Strength (σ0.2): ≥ 220 MPa (ensuring the round bar does not undergo excessive deformation under high - temperature loads)

- Creep Rupture Strength (1000h, σr): ≥ 120 MPa (excellent creep resistance, ensuring long - term service life in high - temperature and constant load conditions)

4. Performance Characteristics

4.1 Exceptional Corrosion Resistance

Hastelloy C22 nickel alloy round bar exhibits outstanding corrosion resistance in a wide range of aggressive media. It has excellent resistance to both oxidizing and reducing acids, such as sulfuric acid, hydrochloric acid, nitric acid, and acetic acid. Even in mixed acid environments with high concentrations and high temperatures, it can maintain good corrosion resistance, effectively preventing pitting, crevice corrosion, and intergranular corrosion. This makes it an ideal choice for chemical processing equipment, oil and gas exploration and production components, and other applications exposed to corrosive media.

4.2 Excellent High - Temperature Performance

With its unique alloy composition, the round bar shows excellent high - temperature strength and oxidation resistance. It can operate stably for a long time in high - temperature environments up to 1093°C, without significant degradation in mechanical properties or severe oxidation. Moreover, it has good creep and stress rupture resistance, which can withstand the long - term effects of high - temperature and constant loads, making it suitable for high - temperature furnace components, aerospace engine parts, and other high - temperature applications.

4.3 Good Mechanical Processing Performance

Despite its high strength and excellent corrosion resistance, Hastelloy C22 nickel alloy round bar still has good mechanical processing performance. It can be processed through various conventional processing methods, such as turning, milling, drilling, and grinding. However, due to its high hardness and strength, appropriate cutting tools and processing parameters should be selected during processing to ensure processing accuracy and surface quality. In addition, it has good weldability and can be welded using common welding methods (such as TIG welding and MIG welding) to form reliable welded joints with excellent performance.

4.4 Outstanding Structural Stability

The alloy has a stable austenitic structure, which does not undergo phase transformation during service, ensuring consistent mechanical properties and corrosion resistance. Even after long - term use in harsh environments, there is no risk of structural embrittlement or performance degradation, providing long - term reliability and safety for the equipment and components made from it.

5. Executive Standards

The production and quality control of Hastelloy C22 nickel alloy round bar strictly comply with the following international standards to ensure product quality and performance consistency:

- ASTM Standard: ASTM B622 (Standard Specification for Nickel - Chromium - Molybdenum - Tungsten Alloy (UNS N06022) Plate, Sheet, and Strip) and ASTM B619 (Standard Specification for Nickel - Chromium - Molybdenum Alloy (UNS N06625, N06022, N06600, N06690, N06700, N06718, and N06852) Rod and Bar). These standards specify the chemical composition, mechanical properties, dimensional tolerances, surface quality, and testing methods of the round bar.

- EN Standard: EN 10088 - 3 (Stainless steels - Part 3: Technical delivery conditions for semi - finished products, bars, rods, and sections of corrosion - resistant steels for general purposes). This standard provides detailed requirements for the delivery of corrosion - resistant alloy round bars, including quality control, inspection, and certification.

- DIN Standard: DIN 17752 (Nickel and nickel alloys - Rods and bars). This standard specifies the technical parameters and testing requirements for nickel alloy rods and bars, ensuring that the product meets the high - quality standards of the German industry.

6. Similar Grades

Hastelloy C22 nickel alloy round bar has some similar grades in the international market, which have similar chemical compositions and performance characteristics, but may have slight differences in specific indicators, suitable for different application scenarios:

- UNS N06625 (Hastelloy C276): This grade has a higher molybdenum content, which provides better resistance to pitting and crevice corrosion in strong reducing environments. However, its high - temperature strength is slightly lower than that of Hastelloy C22. It is commonly used in chemical processing, marine engineering, and other fields.

- UNS N06059 (Hastelloy X): This grade has excellent high - temperature oxidation resistance and creep strength, making it suitable for high - temperature applications such as aerospace engine combustion chambers and industrial furnace linings. Its corrosion resistance in acidic environments is slightly inferior to that of Hastelloy C22.

- Alloy 2.4605 (Hastelloy C4): This grade has a lower carbon content and silicon content, which significantly improves its resistance to intergranular corrosion. It is suitable for applications in high - temperature and corrosive environments where intergranular corrosion is a major concern, such as chemical reactors and heat exchangers.

7. Application Fields

Due to its excellent comprehensive performance, Hastelloy C22 nickel alloy round bar is widely used in various industrial fields:

- Chemical Industry: It is used to manufacture components of chemical reactors, heat exchangers, pipelines, valves, and pumps. These components are often exposed to various corrosive chemicals, and the excellent corrosion resistance of Hastelloy C22 ensures the long - term stable operation of the equipment.

- Oil and Gas Industry: In oil and gas exploration, production, and refining processes, the round bar is used to make downhole tools, wellhead equipment, pipelines, and pressure vessels. It can withstand the corrosion of sour oil and gas (containing hydrogen sulfide, carbon dioxide, etc.) and the harsh working conditions of high temperature and high pressure.

- Aerospace Industry: It is used to produce high - temperature components of aircraft engines, such as turbine blades, combustion chambers, and exhaust systems. Its excellent high - temperature strength and oxidation resistance ensure the safe and reliable operation of the engine under extreme conditions.

- Pharmaceutical Industry: The high purity and excellent corrosion resistance of Hastelloy C22 make it suitable for manufacturing pharmaceutical equipment, such as drug synthesis reactors, storage tanks, and pipelines. It can avoid the contamination of drugs by metal ions and ensure the quality and safety of pharmaceuticals.

- Environmental Protection Industry: In waste treatment, flue gas desulfurization, and other environmental protection projects, the round bar is used to make equipment such as scrubbers, filters, and pipelines. It can resist the corrosion of acidic and alkaline waste liquids and flue gases, ensuring the normal operation of environmental protection equipment.

- Food Processing Industry: It is used to manufacture food processing equipment, such as mixing tanks, conveyors, and heat exchangers. The alloy is non - toxic and has good corrosion resistance to food acids and alkalis, ensuring the hygiene and safety of food processing.

8. Packaging and Transportation

8.1 Packaging

To ensure that the Hastelloy C22 nickel alloy round bar is not damaged during storage and transportation, and to prevent corrosion and contamination, the following packaging methods are adopted:

- Inner Packaging: Each round bar is first wrapped with a layer of moisture - proof plastic film to isolate it from air and moisture, preventing oxidation and corrosion. For small - diameter round bars, they can be bundled into small bundles with plastic straps, and each bundle is wrapped with moisture - proof paper.

- Outer Packaging: The inner - packaged round bars are placed in strong wooden cases or steel crates. The wooden cases are made of high - quality hardwood, which has good load - bearing capacity and impact resistance. The interior of the cases is filled with soft materials (such as foam plastic) to prevent the round bars from colliding with each other during transportation. The steel crates are made of thick steel plates, which are more durable and suitable for long - distance sea transportation.

- Labeling: Each package is clearly labeled with product information, including product name (Hastelloy C22 nickel alloy round bar), grade (Alloy 2.4602 / UNS N06022), diameter, length, quantity, batch number, production date, manufacturer's name, and contact information. In addition, labels such as "Moisture - proof", "Shock - proof", "No Heavy Pressure", and "Direction of Placement" are also attached to remind the handlers to pay attention during transportation and storage.

8.2 Transportation

- Mode of Transportation: According to the quantity of products, destination, and customer requirements, appropriate transportation methods are selected, including road transportation, railway transportation, sea transportation, and air transportation. For large - quantity and long - distance transportation, sea transportation is usually chosen, which is cost - effective. For urgent orders or small - quantity products, air transportation can be selected to ensure the timely delivery of products. Road transportation and railway transportation are suitable for short - distance and medium - distance transportation, with the advantages of flexibility and fast delivery.

- Transportation Conditions: During transportation, the packages should be placed stably to avoid tilting, collision, and extrusion. The transportation vehicles or containers should be clean, dry, and free from corrosive substances. In case of rainy or snowy weather, rainproof and moisture - proof measures should be taken to prevent the packages from getting wet. For sea transportation, the containers should be checked for tightness to prevent seawater from entering.

- Transportation Documentation: Complete transportation documentation is provided, including commercial invoice, packing list, bill of lading (for sea transportation) or air waybill (for air transportation), certificate of quality, and certificate of origin. These documents are necessary for customs clearance and product acceptance at the destination, ensuring the smooth progress of the transportation process.

![]()

![]()

![]()

![]()

Geadviseerde Producten