-

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

Raian IonescuMateriële zeer goede kwaliteit. wij hebben samenwerken meer dan 10 Jaar. Zij wisselen partijensoorten staalmateriaal uit. Al materieel kwaliteitsgoed. Zij plicht voor al materiële kwaliteit. Wij schaven verdergaan samenwerken met hen in de toekomst

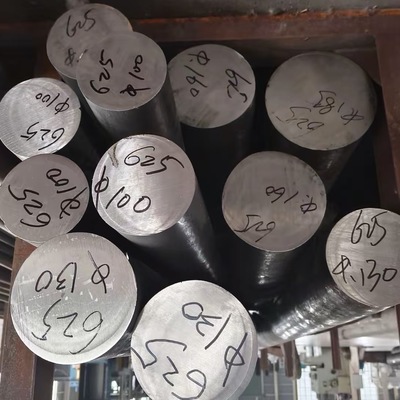

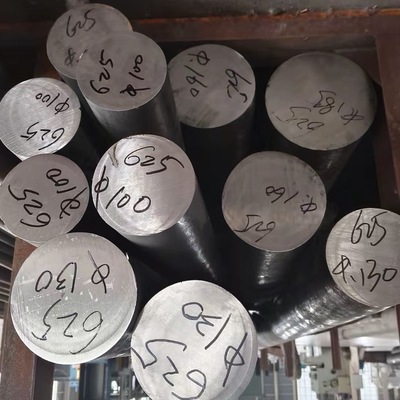

ASTM-Standard Inconel 625 Nickel Alloy Round Bars in Custom Sizes

| Plaats van herkomst | CHINA |

|---|---|

| Merknaam | DELTA |

| Certificering | ISO |

| Modelnummer | Inconel 625 |

| Min. bestelaantal | 10 kg |

| Prijs | 20 - 35 USD/Kg |

| Verpakking Details | Standaardverpakking voor export |

| Levertijd | 5 - 12 dagen op basis van de hoeveelheid |

| Betalingscondities | L/C, T/T, Western Union |

| Levering vermogen | 3 ton per week |

| Producten | Inconel 625 Ronde Bar | Cijfer | Inconel 625 |

|---|---|---|---|

| Diameter | 10 - 350mm | Lengte | op aanvraag op maat gesneden |

| Standaard | Astm en | Dienst | Snij |

| Laadpoort | Shanghai -haven | Oppervlak | Zwart, Helder |

| Markeren | ASTM-standard Inconel 625 round bars,custom-sized nickel alloy bars,Inconel 625 nickel alloy rods |

||

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725 Incoloy series: 800 800H 825 925 Hastelloy series: B,B2,B3,C,C-276,C-4,C-22 Pure: Ni200, Ni201 |

||

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

|

Width

|

1~1500mm

|

||

|

Square bar

|

Size: 4*4-100*100mm

|

||

|

Length

|

2m, 5.8m, 6m, or as required.

|

||

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

||

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

||

|

Package

|

Export standard package, bundled or be required.

The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

||

ASTM-Standard Inconel 625 Nickel Alloy Round Bars in Custom Sizes

ASTM-Standard Inconel 625 Nickel Alloy Round Bars are high-performance materials designed for extreme service conditions, offering an exceptional balance of strength, corrosion resistance, and manufacturability. These round bars are produced according to strict international standards, primarily ASTM B446, ensuring consistency and reliability for critical applications across aerospace, marine, and chemical processing industries .

This article provides a detailed overview of these custom-sized round bars, covering their chemical composition, mechanical properties, standards, key characteristics, applications, and packaging.

1 Chemical Composition

The outstanding properties of Inconel 625 are derived from its precise nickel-chromium base enhanced with solid-solution strengthening elements like molybdenum and niobium. The following table outlines its typical chemical composition as per standard specifications .

|

Element |

Content (%) |

Element |

Content (%) |

|---|---|---|---|

|

Nickel (Ni) |

Balance (approx. 58% min) |

Iron (Fe) |

≤ 5.0 |

|

Chromium (Cr) |

20.0 - 23.0 |

Aluminum (Al) |

≤ 0.40 |

|

Molybdenum (Mo) |

8.0 - 10.0 |

Titanium (Ti) |

≤ 0.40 |

|

Niobium (Nb) |

3.15 - 4.15 |

Carbon (C) |

≤ 0.10 |

|

Cobalt (Co) |

≤ 1.0 |

Manganese (Mn) |

≤ 0.50 |

|

Silicon (Si) |

≤ 0.50 |

Phosphorus (P) |

≤ 0.015 |

|

Copper (Cu) |

≤ 0.07 |

Sulfur (S) |

≤ 0.015 |

The combination of chromium provides excellent resistance to oxidation and corrosion, while molybdenum and niobium confer strength and resistance to pitting and crevice corrosion, particularly in chloride-ion environments . The low carbon content enhances its weldability by minimizing carbide precipitation .

2 Mechanical Properties

Inconel 625 round bars are typically supplied in the annealed or solution-treated condition, offering a superb combination of high strength and good ductility. The mechanical properties meet or exceed the minimum requirements of standards like ASTM B446 .

-

Density: 8.4 g/cm³ (0.305 lb/in³)

-

Melting Range: 1290 - 1350 °C (2350 - 2460 °F)

The table below presents typical mechanical properties at room temperature for solution-treated bars 110.

|

Property |

Typical Value |

Remarks |

|---|---|---|

|

Tensile Strength |

≥ 830 MPa (120 ksi) |

May increase significantly with cold work . |

|

Yield Strength (0.2% Offset) |

≥ 415 MPa (60 ksi) |

|

|

Elongation (in 50 mm) |

≥ 30% |

Indicates good ductility |

|

Hardness (Brinell) |

150 - 220 HB |

|

A key advantage of Inconel 625 is that its high strength is achieved through solid-solution strengthening by molybdenum and niobium, meaning it does not require precipitation hardening treatments . This makes it particularly suitable for applications involving welding, as it retains its properties in the as-welded condition without post-weld heat treatment for stress relief in many cases .

3 Applicable Standards

ASTM-standard Inconel 625 round bars are governed by specific specifications that ensure material quality and consistency.

-

Primary Standard for Bars: ASTM B446 / ASME SB-446: This standard covers the requirements for nickel-chromium-molybdenum-columbium (niobium) alloy (UNS N06625) rods and bars .

-

Other Relevant Standards:

-

ASTM B564: Standard for forged fittings and components made from this alloy .

-

AMS 5666: Aerospace Material Specification governing the alloy for high-temperature applications .

-

These standards strictly define the chemical composition limits, heat treatment processes (typically solution annealing at 1090-1200°C followed by rapid cooling ), and minimum mechanical properties .

4 Key Characteristics and Advantages

Inconel 625 round bars are chosen for demanding applications due to their unique set of properties :

-

Excellent Corrosion Resistance: They exhibit outstanding resistance to a wide range of severe corrosive environments, including oxidation, reduction, pitting, and crevice corrosion. They are highly resistant to chloride-induced stress corrosion cracking.

-

High-Temperature Strength: The alloy retains a significant portion of its strength at elevated temperatures, making it suitable for service from cryogenic temperatures up to about 980°C (1800°F) .

-

Outstanding Fabricability: These round bars possess good machinability and can be welded readily using common techniques like TIG, MIG, and plasma arc welding without post-weld heat treatment cracking susceptibility .

-

High Strength and Toughness: The solid-solution strengthening provides high tensile and fatigue strength, along with excellent toughness at both cryogenic and elevated temperatures.

5 Common Applications

Custom-sized Inconel 625 round bars are machined into critical components for various industries :

-

Aerospace Industry: Engine components, thrust reversers, ducting systems, and rocket motor cases.

-

Marine and Offshore Engineering: Propeller blades, submarine parts, mooring cables, and pump shafts for seawater handling due to superior resistance to seawater corrosion.

-

Chemical Processing Industry: Agitators, heat exchanger tubes, reaction vessels, and piping systems handling acidic chlorides and other aggressive chemicals.

-

Pollution Control: Components in flue gas desulfurization systems, such as absorber towers, dampers, and fan blades.

-

Nuclear Industry: Core components and control rod mechanisms due to their high-temperature strength and corrosion resistance.

6 Packaging Options

To ensure the material arrives in perfect condition, especially for high-value alloys like Inconel 625, suppliers typically offer robust packaging solutions. While specifics can vary, common practices include 58:

-

Individual Protection: Each round bar is often coated with anti-corrosive oil and wrapped individually.

-

Secured Bundling: Bars are neatly bundled using steel straps to prevent movement during transit.

-

Marking and Labeling: Clear markings indicating the material grade, heat number, size, and other traceability information are essential.

-

External Packaging: Bundles are typically packed in wooden crates or cases for maximum protection during shipping and handling.

7 Conclusion

In summary, ASTM-standard Inconel 625 round bars in custom sizes are a premier choice for engineers dealing with extreme environments. Their robust chemical composition, governed by standards like ASTM B446, delivers a reliable combination of high strength, exceptional corrosion resistance, and excellent fabricability. Whether for aerospace, marine, or chemical processing applications, these round bars offer the performance and reliability needed for critical components, backed by professional packaging that ensures they arrive on-site ready for machining and installation.

![]()

![]()

![]()

![]()