-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

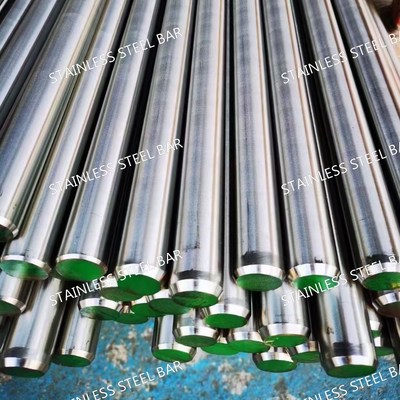

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Barras redondas versátiles de acero inoxidable 303 para uso automotriz y de herramientas

| Lugar de origen | Porcelana |

|---|---|

| Nombre de la marca | Delta |

| Certificación | ISO 9001 |

| Número de modelo | 303 / 303F |

| Cantidad de orden mínima | 500 kgs |

| Precio | 2.8 -3.5 USD/Kg |

| Detalles de empaquetado | caja de madera o envolvente de papel resistente al agua |

| Tiempo de entrega | 5 - 10 días |

| Condiciones de pago | T/T, Unión Occidental |

| Capacidad de la fuente | 50 toneladas por mes |

| Nombre de los productos | Barra de acero inoxidable 303 | Diámetro | 10 - 350m m |

|---|---|---|---|

| Longitud | 6m o cortar cualquier longitud según la solicitud | Superficie | Encurtidos o brillantes |

| SERVICIO | Corte | Estándar | ASTM DIN GB EN |

| Otros productos | barra redonda, barra cuadrada, barra plana.etc | Técnica | Rollado caliente |

| Resaltar | barra redonda de acero inoxidable 303,barras de acero inoxidable para automóviles,barras de herramientas de acero inoxidable versátiles |

||

Barras redondas versátiles de acero inoxidable 303 para uso automotriz y de herramientas

Especificación de los productos

| Nombre del producto | Barras redondas de acero inoxidable 303 |

| Grado |

303,304- 304L 309S 310S 310H 316L 316Ti 316H 317L321,329,347,410,415,420, 430F,431,440A/B/C,2205,2507,904l,254SMO,253MA,CD4MCU,XM-19,17-4PH,15-5PH,17-7PH,660,C276,600,601,625,718,800,800H,825,926.etc. |

| Producto Rango de diámetro | Se aplicarán las siguientes medidas: |

| Duración | 6 m/pcs o cortando cualquier longitud a petición |

| Superficie | Con acabado de decapado, acabado brillante |

| Estándar | Las condiciones de los requisitos de seguridad de los vehículos de motor y los requisitos de seguridad de los vehículos de motor. |

| Servicio | Cortado |

| Otras formas | Cuadrado, plano, hexagonal, redondo, etc. |

| Puerto de carga | Puerto de Shanghai |

| Cuota de producción | 500 kg |

Barras redondas versátiles de acero inoxidable 303 para uso automotriz y de herramientas

Resumen del producto

El...Barras redondas de acero inoxidable 303es un producto avanzado de acero inoxidable de alta calidad diseñado principalmente para aplicaciones en industrias como la automoción, herramientas, fabricación y más.Esta barra redonda ofrece una excelente maquinabilidad, lo que lo hace ideal para componentes de precisión, sujetadores y otras piezas de alto rendimiento.la barra redonda de acero inoxidable 303 cumple con las demandas funcionales y estéticas, por lo que es adecuado para una amplia gama de aplicaciones.

Acero inoxidable 303, también conocido comoAISI 303, es una aleación versátil que combina una excelente maquinabilidad con una buena resistencia a la corrosión y la oxidación.mejora su maquinabilidad y lo hace ideal para operaciones de mecanizado complejas como girarLa superficie pulida brillante asegura que la barra sea a la vez visualmente atractiva y altamente funcional.

Parámetros del producto

| Parámetro | Especificación |

|---|---|

| El material | 303 Acero inoxidable (aleación 303) |

| Rango de diámetro | 3 mm - 200 mm (disponible en tamaños personalizados) |

| Duración | Hasta 4 metros (longitudes personalizadas a petición) |

| Acaba. | Brillante pulido, acabado espejo |

| Densidad | 70,90 g/cm3 |

| Resistencia a la tracción | Se aplicarán las siguientes medidas: |

| Fuerza de rendimiento | Se aplicarán las siguientes medidas: |

| Elongado | 40% (mínimo) |

| Dureza (Brinell) | 201 HB |

| Conductividad térmica | 16.2 W/m·K |

| Resistencia eléctrica | 0.73 x 10−6 Ω·m |

| Finalización de la superficie | Espejo o pulido |

| Funcionalidad | Excelente para el mecanizado |

Principales características y beneficios

-

Excelente capacidad de mecanización

El alto contenido de azufre en el acero inoxidable 303 mejora su maquinabilidad, lo que permite que se procese fácilmente utilizando herramientas de alta velocidad.Es el material de elección para operaciones de mecanizado complejas y de precisión, como cortar, roscar y girar. -

Resistencia a la corrosión superior

Al igual que todos los aceros inoxidables, el 303 proporciona un alto nivel de resistencia a la oxidación y la corrosión, particularmente en ambientes suaves.Aunque no es adecuado para ambientes altamente corrosivos como marinos o ácidos, es ideal para muchas aplicaciones industriales y comerciales que se enfrentan a un estrés ambiental moderado. -

Finalización estética

El acabado pulido brillante no sólo mejora la apariencia del material, sino que también lo hace adecuado para aplicaciones donde el atractivo visual es importante,como en la fabricación de productos de consumo o en aplicaciones decorativas. -

No magnético

En su estado recocido, el acero inoxidable 303 no es magnético, por lo que es adecuado para aplicaciones donde las propiedades magnéticas podrían interferir con el rendimiento o la funcionalidad,como en productos electrónicos o dispositivos médicos. -

Fuerza y durabilidad

El material es resistente, duradero y capaz de soportar tensiones mecánicas, lo que lo convierte en una opción confiable para piezas que deben conservar su integridad bajo tensión, como sujetadores, ejes,y componentes de precisión.

Normas y especificaciones

-

Las demás partidasEspecificación estándar para barras y formas de acero inoxidable

-

Las demás partidas de los componentes de las placasEspecificación estándar para barras de acero inoxidable para uso en calderas y otros recipientes a presión

-

Las condiciones de los productos de la UNS S30300Sistema de numeración unificado de los grados de acero inoxidable

-

Las demás especificacionesBarras y varillas de acero inoxidable

-

Las normas ISO 3506-1️ Fijaciones de acero inoxidable ️ Parte 1: tornillos, tornillos y pernos

-

AISI 303¢ Norma del Instituto Americano del Hierro y del Acero para la aleación de acero inoxidable 303

Leguras y grados similares

Si está considerando alternativas a la barra redonda de acero inoxidable 303, aquí hay algunas aleaciones similares con propiedades comparables:

| Grado | Descripción | Mecanizabilidad | Resistencia a la corrosión |

|---|---|---|---|

| 304 | Acero inoxidable estándar, muy resistente a la corrosión | Es bueno. | Es excelente. |

| 316 | Acero inoxidable con adición de molibdeno para una mejor resistencia a la corrosión, especialmente en entornos marinos | Es justo. | Muy bueno (grado marino) |

| 303Se | Una variación de 303 con selenio para mejorar la maquinabilidad | Es excelente. | Es bueno. |

| 416 | Acero inoxidable martensítico de mayor resistencia pero menor resistencia a la corrosión que el 303 | Es justo. | Es justo. |

Aplicaciones de la barra redonda de acero inoxidable 303

Las barras redondas de acero inoxidable 303 se utilizan en varias industrias.

-

Industria del automóvil

Se utiliza para la fabricación de piezas automotrices como sujetadores, ejes y componentes estructurales que requieren una alta resistencia, resistencia a la corrosión y facilidad de mecanizado. -

Fabricación de herramientas y equipos

Ideal para producir herramientas de precisión, medidores y componentes mecánicos como engranajes, pines y bujes que requieren una alta maquinabilidad y durabilidad. -

Aeroespacial y Defensa

Debido a sus propiedades no magnéticas, el acero inoxidable 303 se utiliza a menudo en la producción de piezas para aplicaciones aeroespaciales y de defensa sensibles donde se necesitan materiales no magnéticos. -

Equipo de procesamiento de alimentos

Su resistencia a la corrosión lo hace adecuado para piezas que entran en contacto con alimentos o bebidas, como válvulas, sujetadores y accesorios en maquinaria de producción de alimentos. -

Dispositivos médicos

La naturaleza no corrosiva y biocompatible del acero inoxidable 303 lo hace adecuado para herramientas quirúrgicas, implantes médicos e instrumentos que necesitan ser esterilizados y expuestos a varios productos químicos. -

Electrónica

Se utiliza en la producción de conectores eléctricos, pines y carcasas, donde tanto la resistencia mecánica como el acabado estético de la superficie son esenciales. -

Fabricación de accesorios y elementos de fijación

El acero inoxidable 303 se utiliza ampliamente en la producción de sujetadores y accesorios de precisión que requieren un excelente acabado superficial y una precisión dimensional.

Embalaje y envío

El...Barras redondas de acero inoxidable 303En función de su tamaño y cantidad, los métodos de envasado incluyen:

-

Embalaje estándar: Las barras se envuelven en una película de plástico para evitar la exposición a la humedad durante el transporte.

-

Embalaje a medida: Si es necesario, el embalaje se puede personalizar para satisfacer necesidades específicas de transporte o almacenamiento.

-

Etiquetado: Cada paquete está claramente etiquetado con las especificaciones del producto, los números de lotes y los códigos de trazabilidad para garantizar un manejo y una gestión adecuados de los inventarios.

Transporte marítimo:

Las barras generalmente se envían por mar, aire o transporte por carretera, dependiendo del destino y los requisitos del cliente.Nos aseguramos de que todos los envíos se realizan de acuerdo con los estándares internacionales y se entregan de forma segura.

Preguntas frecuentes (FAQ)

P1: ¿Cuál es la diferencia entre el acero inoxidable 303 y 304?

R1: La diferencia clave es que el 303 contiene azufre para mejorar la maquinaria, lo que hace que sea más fácil de maquinaria que el 304.El 304 ofrece una resistencia superior a la corrosión y se prefiere para aplicaciones que requieren una mayor resistencia a los ácidos y cloruros.

P2: ¿Puedo soldar acero inoxidable 303?

R2: Sí, el acero inoxidable 303 se puede soldar, pero no es tan fácil de soldar como otros grados de acero inoxidable como el 304.El precalentamiento del material y el uso de material de relleno adecuado pueden ayudar a asegurar una soldadura exitosa.

P3: ¿Es el acero inoxidable 303 magnético?

A3: En su estado recocido, el acero inoxidable 303 no es magnético. Sin embargo, puede desarrollarse cierto magnetismo durante los procesos de trabajo en frío.

P4: ¿Cuáles son las aplicaciones ideales para el acero inoxidable 303?

A4: El acero inoxidable 303 es el más adecuado para aplicaciones que requieren alta maquinabilidad, resistencia a la corrosión moderada y buena resistencia mecánica.piezas de automóviles, dispositivos médicos y herramientas.

P5: ¿Puede el acero inoxidable 303 ser tratado térmicamente?

A5: El acero inoxidable 303 no es ideal para el tratamiento térmico ya que es un grado austenítico, que no endurece. Sin embargo, se puede recocer para aliviar la tensión o para lograr una estructura más suave.

Conclusión

El...Barras redondas de acero inoxidable 303es un material versátil y muy fiable ampliamente utilizado en industrias que requieren una excelente maquinariabilidad y buena resistencia a la corrosión.y propiedades no magnéticasLa disponibilidad de tamaños y acabados personalizados, junto con envío y embalaje confiables,garantiza que este producto cumple los más altos estándares de calidad y rendimiento.

![]()

![]()

![]()

![]()