-

Tira de acero inoxidable

-

Hoja de acero inoxidable

-

Placa de acero inoxidable

-

tubería de acero inoxidable

-

Barra de acero inoxidable

-

Bobina de acero galvanizada

-

Placa de acero

-

barra redonda de acero

-

aleación de níquel

-

Tubería de acero inconsútil

-

Haz de acero inoxidable

-

Hoja de la placa de cobre

-

Barra redonda de cobre

-

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

Raian IonescuCalidad material muy buena. tenemos cooperar más de 10 años. Negocian clases de las porciones de material de acero. Toda la calidad material buena. Ellos deber para toda la calidad material. Estamos acepillando para continuar cooperando con ellos en el futuro

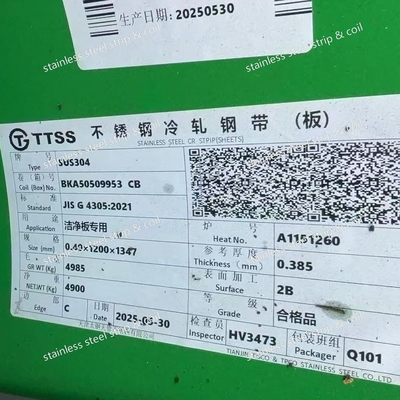

Rollo en frío bobinas de bandas de acero inoxidable 0,1-3,0 mm espesor 5-1219 mm anchura

| Lugar de origen | China |

|---|---|

| Nombre de la marca | TISCO |

| Certificación | ISO |

| Número de modelo | Serie 300 / Serie 400 |

| Cantidad de orden mínima | 2 toneladas |

| Precio | 1500-2500 USD/Ton |

| Detalles de empaquetado | Embalaje estándar para la exportación |

| Tiempo de entrega | 5 - 12 días en función de la cantidad |

| Condiciones de pago | L/C, T/T, Western Union |

| Capacidad de la fuente | 20 toneladas por semana |

Éntreme en contacto con gratis las muestras y los vales.

whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Si usted tiene alguna preocupación, proporcionamos ayuda en línea de 24 horas.

x| Productos | banda de acero inoxidable | El grosor | 0.5-8.0m m |

|---|---|---|---|

| Ancho | en 1500 milímetro | Cuota de producción | 500 kg |

| Grado | Serie 200 serie 300 serie 300 | Superficie | BA 2B NO.4 HL 8K NO.1 |

| Estándar | Se aplicarán las siguientes medidas: | packing | marco de madera y papel a prueba de agua |

| Resaltar | Fleje de acero inoxidable laminado en frío,bobinas de acero inoxidables de la tira,banda de acero inoxidable de 0 |

||

| Atributo | Valor |

|---|---|

| Productos | fleje de acero inoxidable |

| Espesor | 0,5-8,0 mm |

| Ancho | dentro de 1500 mm |

| MOQ | 500 kg |

| Grado | Serie 200, serie 300, serie 300 |

| Superficie | BA 2B NO.4 HL 8K NO.1 |

| Estándar | ASTM EN GB JIS |

| Embalaje | marco de madera y papel a prueba de agua |

Nuestras bobinas de fleje de acero inoxidable laminado en frío están diseñadas con precisión utilizando tecnología avanzada de laminación en frío, lo que ofrece una precisión dimensional, un acabado superficial y unas propiedades mecánicas superiores. Con un espesor que oscila entre 0,1 mm y 3,0 mm y anchos de corte por ranurado de 5 mm a 1219 mm, estas tiras son ideales para aplicaciones que requieren alta precisión, resistencia a la corrosión y conformabilidad. Disponibles en grados populares como 201, 304, 316L, 410 y 430, nuestros productos sirven a diversas industrias, incluyendo la electrónica, la automotriz, la aeroespacial, los dispositivos médicos y la fabricación de precisión. El proceso de laminación en frío mejora la dureza del material, la resistencia a la tracción y la suavidad de la superficie, mientras que nuestro corte por ranurado sin rebabas garantiza un procesamiento posterior mínimo y un rendimiento óptimo en aplicaciones críticas.

| Parámetro | Detalles |

|---|---|

| Grados de material | 201, 304, 316L, 301, 410, 430 (estándares AISI/ASME/JIS/EN) |

| Espesor | 0,1 mm - 3,0 mm (Tolerancia: ±0,01 mm para espesor ≤1 mm; ±0,02 mm para >1 mm) |

| Ancho | 5 mm - 1219 mm (Tolerancia de corte por ranurado: ±0,1 mm para ancho ≤200 mm; ±0,2 mm para >200 mm) |

| Dureza (HV) | Blando (140-200), Semiduro (250-350), Duro (380-450), Duro de resorte (500-600) |

| Acabado superficial | 2B (Acabado de laminación), BA (Recocido brillante), No.4 (Pulido), Espejo 8K, Cepillado, Antihuellas |

| Resistencia a la tracción | 550-1600 MPa (Dependiente del grado y la dureza) |

| Alargamiento a la rotura | ≥15% (Temple blando, dependiente del grado) |

| Proceso | Laminado en frío (CR) con opciones de recocido (recocido completo/parcial disponible) |

- Peso de la bobina: 50 kg - 2000 kg por bobina (Personalizable según el espesor/ancho)

- Diámetro interior: 305 mm (Estándar para tiras estrechas), 508 mm (Estándar para bobinas anchas)

- Diámetro exterior: Hasta 1500 mm (Sujeto al peso y espesor de la bobina)

- Longitud de las tiras rectas: 100 mm - 6000 mm (Corte de precisión con bordes sin rebabas)

| Grado | Propiedades clave | Aplicaciones típicas |

|---|---|---|

| 304 | Excelente resistencia a la corrosión, ductilidad | Equipamiento de cocina, instrumentos médicos |

| 316L | Alta resistencia a la corrosión por cloruros | Componentes marinos, procesamiento químico |

| 201 | Rentable, buena conformabilidad | Adornos decorativos, componentes de muebles |

| 410 | Martensítico, alta dureza/resistencia al desgaste | Herramientas de corte, válvulas, piezas de bomba |

| 430 | Ferrítico, magnético, resistencia a la corrosión bajo tensión | Tubos de escape de automóviles, piezas de electrodomésticos |

- Ventajas del laminado en frío:

- Propiedades mecánicas mejoradas (mayor resistencia a la tracción y dureza)

- Espesor y planitud uniformes para una fabricación precisa

- Acabado superficial liso (RA ≤1,6μm para acabado 2B) que reduce las necesidades de revestimiento/procesamiento

- Corte por ranurado de precisión:

- Bordes sin rebabas logrados a través de líneas de corte avanzadas con inspección automática de bordes

- Anchos personalizados de hasta 5 mm para componentes intrincados

- Opciones de superficie versátiles:

- Amplia gama de acabados para satisfacer los requisitos estéticos (pulido espejo) y funcionales (anticorrosión)

- Capacidad de personalización:

- Niveles de dureza, pesos de bobina y tratamientos superficiales especiales a medida disponibles bajo petición

- Entrega rápida para tamaños no estándar

- Calidad constante:

- Estricto control de calidad en cada etapa (prueba de materia prima, monitoreo del proceso, inspección final)

- Normas de materiales:

- ASTM A240 (Placa, lámina y fleje de acero inoxidable)

- JIS G4305 (Fleje de acero inoxidable laminado en frío)

- EN 10088-2 (Aceros inoxidables para uso general)

- GB/T 3280 (Lámina y fleje de acero inoxidable laminado en frío)

- Certificaciones: Se proporcionan Certificados de prueba de fábrica (MTC) para cada lote, incluida la composición química, las propiedades mecánicas y los registros de tratamiento térmico

- Protección interior:

- Envuelto con papel resistente a la humedad o película de PE para evitar la oxidación y los arañazos

- Bordes protegidos con tiras de cartón para bobinas de ancho ≥500 mm

- Embalaje exterior:

- Paletizado de forma segura en cajas de madera con flejes de acero para envíos internacionales

- Bobinas ligeras (≤200 kg) embaladas en cajas de cartón corrugado con protectores de esquinas

- Etiquetado: Marcado claro con grado, espesor, ancho, dureza, número de lote y detalles del pedido del cliente

- Garantía de calidad:

- Inspección dimensional y superficial al 100% antes del envío

- Pruebas de terceros disponibles bajo petición (por ejemplo, PMI, pruebas de corrosión)

- Garantía: 12 meses de garantía contra defectos de fabricación (excluyendo el mal uso o el almacenamiento inadecuado)

- Soporte técnico: Equipo dedicado a la selección de materiales, la guía de procesamiento (por ejemplo, doblado, soldadura) y la resolución de problemas

- Política de devoluciones: Reemplazo gratuito o reembolso completo por productos no conformes confirmados por inspección mutua

Para consultas personalizadas o para solicitar una muestra, póngase en contacto con nuestro equipo de ventas con sus especificaciones. Estamos comprometidos a entregar flejes de acero inoxidable laminados en frío que combinen precisión, durabilidad y rentabilidad para sus aplicaciones más exigentes.