All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Hot Rolled and Cold Rolled SS Plate 409L Stainless Steel Plate Sheet 2D NO.1 Surface

Product Details

| Products | Stainless Steel Plate | Grade | 409L |

|---|---|---|---|

| Thickness | 0.5-50.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2B NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | Hot Rolled Stainless Steel Plate 409L,Cold Rolled SS Sheet 2D Surface,409L Stainless Steel Plate NO.1 |

||

Product Description

Hot Rolled and Cold Rolled SS Plate 409L Stainless Steel Plate Sheet 2D NO.1 Surface

Stainless Steel Plate Specifications

| Name | 409L stainless steel Plate |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,415,416,420,430,431,436L.439,441,443,444,445,446 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

Hot Rolled and Cold Rolled SS Plate 409L Stainless Steel Plate Sheet – 2D / NO.1 Surface Finish

Product Overview

409L stainless steel is a low-carbon, titanium-stabilized ferritic stainless steel widely recognized for its excellent weldability, formability, and moderate corrosion resistance—particularly in high-temperature environments. It is extensively used in automotive exhaust systems, heat exchangers, agricultural equipment, and industrial applications where cost-effective performance is essential.

Available in both hot rolled (HR) and cold rolled (CR) forms, 409L stainless steel plates and sheets can be supplied with 2D or NO.1 surface finishes, depending on the manufacturing process and end-use requirements. This product information page provides comprehensive technical specifications, application guidance, and comparative data to assist engineers, procurement specialists, and fabricators in selecting the optimal grade and finish for their projects.

Key Features of 409L Stainless Steel

- Low Carbon Content: Minimizes sensitization during welding.

- Titanium Stabilization: Enhances resistance to intergranular corrosion.

- Ferritic Structure: Offers magnetic properties and good thermal conductivity.

- Cost-Effective Alternative: Lower nickel content compared to austenitic grades like 304.

- Good High-Temperature Performance: Suitable for continuous service up to 600–650°C.

Surface Finishes: 2D vs. NO.1

| Feature | 2D Finish | NO.1 Finish |

|---|---|---|

| Process | Cold rolled, annealed, pickled, and lightly descaled | Hot rolled, annealed, and pickled |

| Appearance | Matte, non-reflective, uniform dull gray | Rougher, scaled texture; less refined than 2B or BA |

| Surface Roughness (Ra) | ~1.0–2.5 μm | ~3.0–6.0 μm |

| Typical Use | Industrial components, structural parts, automotive underbodies | High-temperature applications, furnace parts, exhaust manifolds |

| Post-Processing | Can be further polished or coated | Usually used as-is; not ideal for decorative purposes |

Note: While "2D" is typically associated with cold-rolled material, some suppliers may use the term loosely. True 2D finish originates from cold rolling followed by annealing and pickling. NO.1 is exclusively a hot-rolled finish.

Technical Specifications

Chemical Composition (ASTM A240 / JIS G4303)

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.03 |

| Manganese (Mn) | ≤ 1.00 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 10.5–11.75 |

| Nickel (Ni) | ≤ 0.50 |

| Titanium (Ti) | ≥ 6×C (typically 0.10–0.60%) |

Mechanical Properties

| Property | Typical Value |

|---|---|

| Tensile Strength | 400–550 MPa |

| Yield Strength (0.2% offset) | ≥ 170 MPa |

| Elongation | ≥ 20% (in 50 mm) |

| Hardness (HV) | 140–200 (annealed condition) |

| Density | 7.70 g/cm³ |

| Melting Point | ~1425–1510°C |

Available Forms & Dimensions

Hot Rolled 409L Plate/Sheet (NO.1 Finish)

- Thickness: 3.0 mm – 50.0 mm

- Width: 1000 mm – 2000 mm (standard); up to 3000 mm (custom)

- Length: 2000 mm – 6000 mm (cut-to-length available)

- Coil Option: Limited; typically supplied as plate/sheet

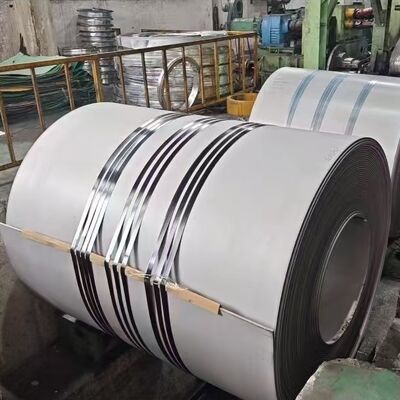

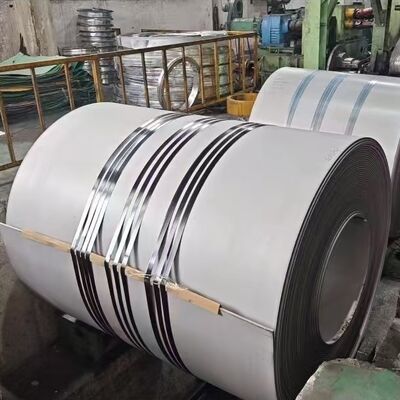

Cold Rolled 409L Sheet (2D Finish)

- Thickness: 0.3 mm – 4.0 mm

- Width: 1000 mm – 1500 mm (standard); up to 2000 mm (special order)

- Length: In coil (up to 10,000 m) or cut-to-length sheets

- Tolerance: Tight thickness tolerance (±0.05 mm for thin gauges)

Customization: Width, length, edge type (mill edge or slit edge), and hardness (HV 145–680 via temper rolling) can be tailored per customer requirements.

Applications

409L stainless steel’s balance of performance and affordability makes it ideal for:

- Automotive Industry: Exhaust pipes, mufflers, catalytic converter shells

- Industrial Equipment: Heat exchangers, burner parts, flue gas ducts

- Agricultural Machinery: Plows, harrows, and other wear-resistant components

- Construction: Non-decorative cladding, support structures in mildly corrosive environments

- Energy Sector: Components in biomass and waste-to-energy plants

Recent innovations include ultra-pure 409L variants developed for closed-circuit cooling towers, achieving 560+ hours in neutral salt spray (NSS) tests—demonstrating enhanced corrosion resistance through advanced refining and titanium control.

Advantages Over Competing Grades

| Comparison | 409L vs. 430 | 409L vs. 304 |

|---|---|---|

| Cost | Lower (less Cr, no Ni) | Significantly lower (no Ni, lower Cr) |

| Weldability | Superior (Ti-stabilized) | Comparable, but 304 more ductile |

| Corrosion Resistance | Moderate (suitable for dry/mild wet) | Lower than 304, but adequate for many industrial uses |

| High-Temp Stability | Better scaling resistance than 430 | Inferior to 304 above 700°C |

| Magnetism | Magnetic (ferritic) | Non-magnetic (austenitic) |

Tip: Choose 409L when budget constraints exist, welding is required, and exposure to aggressive chlorides or acids is minimal.

Processing & Fabrication Guidelines

- Cutting: Plasma, laser, or mechanical shearing (use sharp tools to avoid work hardening).

- Forming: Good cold formability; avoid sharp bends in thick sections.

- Welding: Excellent with TIG, MIG, or resistance welding. No preheating required. Post-weld annealing not usually necessary due to Ti stabilization.

- Machining: Moderate machinability; use lubricants and slow speeds.

- Surface Treatment: Pickling recommended after welding to restore corrosion resistance. Painting or powder coating enhances longevity in outdoor use.

Quality Assurance & Standards Compliance

Our 409L stainless steel plates and sheets comply with international standards:

- ASTM A240/A240M (Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip)

- JIS G4304 / G4305 (Japanese Industrial Standards)

- EN 10088-2 (European Standard for flat products)

- GB/T 4237 / GB/T 3280 (Chinese National Standards)

Each batch includes:

- Mill Test Certificate (MTC) per EN 10204 3.1

- Spectrometric analysis report

- Dimensional inspection records

- Optional: Ultrasonic testing (for critical applications)

Packaging & Delivery

To ensure surface integrity and prevent moisture damage:

- Sheets: Interleaved with paper or PVC film, strapped on wooden pallets

- Coils: Wrapped in waterproof VCI film, secured with steel banding

- Export Packaging: Fumigated wooden crates (ISPM 15 compliant)

- Lead Time: 7–15 days for standard sizes; 20–30 days for custom orders

Why Choose Our 409L Stainless Steel?

- Source Directly from Leading Mills: Including TISCO (Taiyuan Iron & Steel), Baosteel, and Ningbo Baosteel New Materials.

- Consistent Quality: Advanced ESR (Electroslag Remelting) and AOD (Argon Oxygen Decarburization) processes ensure low inclusion content.

- Technical Support: Our metallurgical team provides application-specific advice on grade selection, processing, and surface finish.

- Global Logistics: FOB Shanghai, Tianjin, or Ningbo; CIF/DDP options available.

Frequently Asked Questions (FAQ)

Q: Is 409L stainless steel magnetic?

A: Yes. As a ferritic stainless steel, it is magnetic—unlike austenitic grades such as 304.

A: Yes. As a ferritic stainless steel, it is magnetic—unlike austenitic grades such as 304.

Q: Can 409L be used outdoors?

A: Yes, but with limitations. It performs well in rural or dry urban atmospheres. For coastal or high-chloride environments, consider 316L.

A: Yes, but with limitations. It performs well in rural or dry urban atmospheres. For coastal or high-chloride environments, consider 316L.

Q: What’s the difference between 409 and 409L?

A: 409L has lower carbon (<0.03%) for improved weldability and reduced risk of sensitization.

A: 409L has lower carbon (<0.03%) for improved weldability and reduced risk of sensitization.

Q: Can I get a mirror finish on 409L?

A: Not recommended. Its ferritic structure doesn’t polish as well as 304/316. For decorative uses, choose austenitic grades.

A: Not recommended. Its ferritic structure doesn’t polish as well as 304/316. For decorative uses, choose austenitic grades.

Conclusion

Hot rolled and cold rolled 409L stainless steel plates and sheets with 2D or NO.1 surface finishes offer a smart engineering solution for applications demanding reliable performance at a competitive price. Whether you need robust exhaust components, durable industrial parts, or cost-efficient structural elements, 409L delivers proven results across global industries.

For detailed quotations, sample requests, or technical consultations, contact our sales team today. We support OEM/ODM services and provide full traceability from melt to delivery.

409L stainless steel plate, hot rolled 409L sheet, cold rolled 409L 2D finish, NO.1 surface stainless steel, ferritic stainless steel 409L, 409L chemical composition, 409L mechanical properties, automotive exhaust stainless steel, titanium stabilized stainless steel, ASTM A240 409L, JIS G4304 409L, 409L vs 430, 409L price per kg, 409L coil supplier, China 409L manufacturer.

Recommended Products