All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

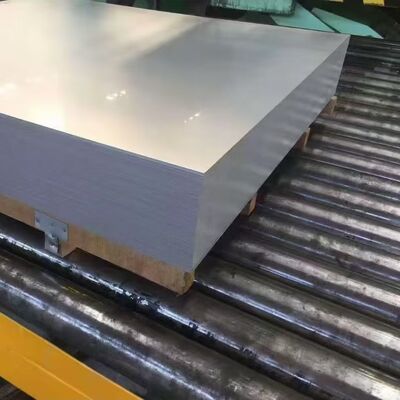

Precision-Ground 416 Stainless Steel Sheet High Machinability & Corrosion Resistance

Product Details

| Products | Stainless Steel Plate | Grade | 416 |

|---|---|---|---|

| Thickness | 0.5-50.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2B NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | 416 stainless steel sheet high machinability,precision-ground stainless steel sheet,corrosion resistant 416 stainless steel |

||

Product Description

Precision-Ground 416 Stainless Steel Sheet High Machinability & Corrosion Resistance

Stainless Steel Plate Specifications

| Name | 416 stainless steel Plate |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,415,416,420,430,431,436L.439,441,443,444,445,446 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

Precision-Ground 416 Stainless Steel Sheet – High Machinability & Corrosion Resistance

Overview

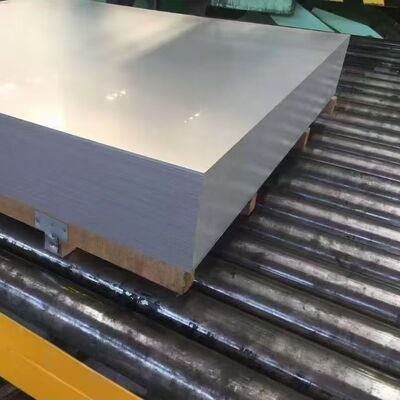

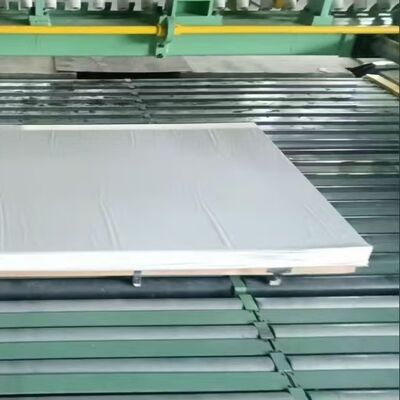

Precision-Ground 416 Stainless Steel Sheet is a premium-grade martensitic stainless steel engineered for applications demanding exceptional machinability, dimensional accuracy, and moderate corrosion resistance. Widely recognized in the manufacturing, automotive, aerospace, and tooling industries, 416 stainless steel stands out due to its unique composition—particularly its controlled sulfur content—which significantly enhances free-machining characteristics without compromising mechanical integrity.

This product offering features sheets that have undergone precision grinding to achieve tight tolerances, smooth surface finishes (typically Ra ≤ 0.8 µm), and uniform thickness across the entire surface. Ideal for high-volume CNC machining, stamping, or precision fabrication, our 416 stainless steel sheets deliver consistent performance, reduced tool wear, and faster production cycles.

Key Features & Benefits

- Superior Machinability: Among the most machinable stainless steels available—up to 85% more machinable than 304 stainless.

- Precision-Ground Surface: Ensures flatness, parallelism, and surface quality suitable for critical components.

- Heat-Treatable: Can be hardened via quenching and tempering to achieve tensile strengths up to 1,000 MPa.

- Moderate Corrosion Resistance: Performs well in mildly corrosive environments (e.g., atmospheric exposure, fresh water).

- Non-Galling Properties: Reduced risk of seizing or galling during machining or assembly.

- Cost-Efficient: Lower machining time and extended tool life reduce overall production costs.

Typical Applications

- Valve and pump shafts

- Gears, spindles, and fasteners

- Surgical and dental instruments

- Automotive trim and fittings

- Food processing equipment (non-acidic environments)

- Precision jigs and fixtures

⚠️ Note: Due to its sulfur content, 416 stainless steel is not recommended for welding or highly corrosive (e.g., marine or acidic) environments. For such applications, consider 304 or 316 grades.

Chemical Composition (ASTM A276 / AISI 416)

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.15 |

| Manganese (Mn) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.040 |

| Sulfur (S) | ≥ 0.15 |

| Silicon (Si) | ≤ 1.00 |

| Chromium (Cr) | 12.0–14.0 |

| Nickel (Ni) | ≤ 0.60 |

| Iron (Fe) | Balance |

The elevated sulfur content (minimum 0.15%) is key to its free-machining behavior, forming manganese sulfide inclusions that act as chip breakers during cutting.

Mechanical Properties (Annealed Condition)

| Property | Value |

|---|---|

| Tensile Strength | 515–725 MPa (75–105 ksi) |

| Yield Strength (0.2% offset) | 275–415 MPa (40–60 ksi) |

| Elongation at Break | 20–25% |

| Hardness (HB) | 183 max |

| Density | 7.74 g/cm³ |

| Melting Point | 1,450–1,510°C (2,642–2,750°F) |

After heat treatment (e.g., quenching at 980–1,010°C + tempering at 150–650°C), hardness can reach 25–45 HRC with corresponding increases in strength.

Physical Properties

| Property | Value |

|---|---|

| Thermal Conductivity | 24.9 W/m·K @ 100°C |

| Electrical Resistivity | 0.57 µΩ·m |

| Specific Heat Capacity | 460 J/kg·K @ 20°C |

| Coefficient of Thermal Expansion | 10.0 µm/m·°C (20–100°C) |

| Magnetic Permeability | Ferromagnetic (magnetic) |

Its magnetic nature makes 416 suitable for applications requiring magnetic response, unlike austenitic grades (e.g., 304).

Machinability Comparison

| Stainless Steel Grade | Relative Machinability (% of B1112 steel) |

|---|---|

| 416 | 85% |

| 303 | 78% |

| 304 | 45% |

| 17-4 PH | 40% |

Source: ASM International, Project 7000 Stainless Data Sheets

This superior machinability translates to:

- Up to 30% faster cutting speeds

- Reduced power consumption

- Longer insert/tool life

- Better surface finish on machined parts

Available Specifications

| Parameter | Options |

|---|---|

| Thickness | 0.5 mm to 25.0 mm (precision-ground) |

| Width | 100 mm to 1,500 mm |

| Length | 500 mm to 6,000 mm (custom cut-to-length) |

| Surface Finish | Ground (Ra 0.4–0.8 µm), BA, or 2B |

| Temper Condition | Annealed, Hardened & Tempered (H&T) |

| Standards Compliant | ASTM A240, ASTM A276, AISI 416, UNS S41600, JIS SUS416 |

| Packaging | VCI paper, wooden crates, moisture-proof wrapping |

All sheets are ultrasonically tested for internal defects and certified with Mill Test Reports (MTRs) per EN 10204 3.1.

Heat Treatment Guidelines

| Process | Temperature Range | Cooling Method | Resulting Properties |

|---|---|---|---|

| Annealing | 815–900°C | Air cool | Soft, machinable condition (HB ≤ 183) |

| Hardening | 980–1,010°C | Oil or air quench | Martensitic structure, high hardness |

| Tempering | 150–650°C (adjust per strength/toughness needs) | Air cool | Optimized strength & ductility |

Avoid prolonged exposure above 425°C in service to prevent embrittlement.

Corrosion Resistance Performance

While not as corrosion-resistant as 304 or 316, 416 performs adequately in:

- Dry indoor environments

- Mild atmospheric conditions

- Freshwater systems

- Non-chloride chemical exposures

Limitations:

- Poor resistance to chlorides, acids, and salt spray

- Not suitable for marine or coastal applications

- Avoid use in food-grade acidic environments (e.g., vinegar, citrus)

For enhanced corrosion resistance while retaining good machinability, consider 416Se (selenium-modified) or 430F alternatives.

Why Choose Our Precision-Ground 416 Sheets?

✅ Consistent Quality: Every batch meets ASTM/ISO standards with full traceability.

✅ Tight Tolerances: Thickness tolerance ±0.02 mm achievable for critical applications.

✅ Global Supply Chain: Ready stock in North America, Europe, and Asia.

✅ Technical Support: Engineering assistance for material selection and processing.

✅ Eco-Conscious: Recyclable (>90% recycled content possible); RoHS and REACH compliant.

✅ Tight Tolerances: Thickness tolerance ±0.02 mm achievable for critical applications.

✅ Global Supply Chain: Ready stock in North America, Europe, and Asia.

✅ Technical Support: Engineering assistance for material selection and processing.

✅ Eco-Conscious: Recyclable (>90% recycled content possible); RoHS and REACH compliant.

- Precision-ground 416 stainless steel sheet

- High machinability stainless steel plate

- Free-machining martensitic stainless steel

- AISI 416 ground flat stock

- SUS416 stainless steel sheet supplier

- 416 stainless steel for CNC machining

- Corrosion-resistant machinable steel

- ASTM A240 416 stainless sheet

Ordering Information

Contact our sales team for:

- Custom dimensions and surface finishes

- Heat-treated or pre-hardened stock

- Certifications (MTR, RoHS, DFARS)

- Volume discounts (MOQ: 50 kg)

Lead Time: 3–7 days for standard sizes; 2–3 weeks for custom orders.

Recommended Products