Todos os Produtos

-

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

Raian IonescuQualidade material muito boa. nós temos cooperar mais de 10 anos. Trocam tipos dos lotes do material de aço. Toda a qualidade material boa. Eles dever para toda a qualidade material. Nós estamos aplanando para continuar a cooperar no futuro com eles

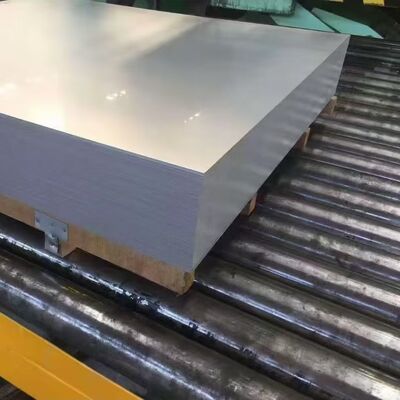

Precision-Ground 416 Chapa de aço inoxidável alta maquinabilidade e resistência à corrosão

| Lugar de origem | China |

|---|---|

| Marca | BAOSTEEL TISCO |

| Certificação | ISO |

| Número do modelo | 416 |

| Quantidade de ordem mínima | 50 kgs |

| Preço | 1.8-2.5USD/Kg |

| Detalhes da embalagem | Embalagem padrão para exportação |

| Tempo de entrega | 5 - 12 dias com base na quantidade |

| Termos de pagamento | L/C, T/T, Western Union |

| Habilidade da fonte | 20ton por semana |

Detalhes do produto

| produtos | placa de aço inoxidável | Nota | 416 |

|---|---|---|---|

| Grossura | 0,5-50,0 mm | Tecnologia | laminado a frio, laminado a quente, forjado |

| Largura | 1000mm 1219mm 1500mm ou costumes como o pedido | Superfície | 2B NÃO.1 |

| Padrão | RUÍDO DO EN DE ASTM GB JIS | Quantidade mínima | 1 tonelada |

| Destacar | 416 Chapa de aço inoxidável,Chapa de aço inoxidável de moagem de precisão,aço inoxidável resistente à corrosão 416 |

||

Descrição de produto

Chapa de Aço Inoxidável 416 Retificada com Precisão - Alta Usinabilidade e Resistência à Corrosão

Especificações da Chapa de Aço Inoxidável

| Nome | Chapa de aço inoxidável 416 |

| Nossa Categoria |

Série 200: 201 202 Série 300: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 Série 400: 409L,410,410S,415,416,420,430,431,436L.439,441,443,444,445,446 Aço Inoxidável Super: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Liga de Níquel: C276, C22,G35,Liga X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Técnica | Laminado a Quente, Laminado a Frio, Forjado |

| Padrão | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Espessura | 0.1 – 80.0mm |

| Faixa de Largura | 10mm – 2000mm |

| Comprimento | Personalizado |

| Acabamento | 2B, BA, No.4, 8k, Escovado, Hairline, Revestimento PVD, Jateado com Areia |

| Serviço | Corte a Laser, Dobramento |

| Amostra | Disponível |

Chapa de Aço Inoxidável 416 Retificada com Precisão – Alta Usinabilidade e Resistência à Corrosão

Visão Geral

A Chapa de Aço Inoxidável 416 Retificada com Precisão é um aço inoxidável martensítico de alta qualidade projetado para aplicações que exigem usinabilidade excepcional, precisão dimensional e resistência moderada à corrosão. Amplamente reconhecido nas indústrias de manufatura, automotiva, aeroespacial e de ferramentas, o aço inoxidável 416 se destaca devido à sua composição única — particularmente seu teor de enxofre controlado — que aprimora significativamente as características de usinagem livre sem comprometer a integridade mecânica.

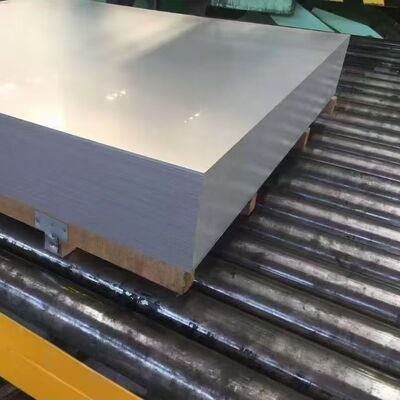

Esta oferta de produto apresenta chapas que passaram por retificação de precisão para obter tolerâncias apertadas, acabamentos de superfície lisos (tipicamente Ra ≤ 0,8 µm) e espessura uniforme em toda a superfície. Ideal para usinagem CNC de alto volume, estampagem ou fabricação de precisão, nossas chapas de aço inoxidável 416 oferecem desempenho consistente, desgaste reduzido da ferramenta e ciclos de produção mais rápidos.

Principais Características e Benefícios

- Usinabilidade Superior: Entre os aços inoxidáveis mais usináveis disponíveis — até 85% mais usinável do que o aço inoxidável 304.

- Superfície Retificada com Precisão: Garante planicidade, paralelismo e qualidade de superfície adequadas para componentes críticos.

- Tratável Termicamente: Pode ser endurecido por meio de têmpera e revenido para obter resistências à tração de até 1.000 MPa.

- Resistência Moderada à Corrosão: Desempenha bem em ambientes levemente corrosivos (por exemplo, exposição atmosférica, água doce).

- Propriedades Anti-Aderentes: Risco reduzido de apreensão ou emperramento durante a usinagem ou montagem.

- Custo-Eficiente: Menor tempo de usinagem e vida útil prolongada da ferramenta reduzem os custos gerais de produção.

Aplicações Típicas

- Eixos de válvulas e bombas

- Engrenagens, fusos e fixadores

- Instrumentos cirúrgicos e odontológicos

- Acabamentos e acessórios automotivos

- Equipamentos de processamento de alimentos (ambientes não ácidos)

- Gabaritos e dispositivos de precisão

⚠️ Nota: Devido ao seu teor de enxofre, o aço inoxidável 416 não é recomendado para soldagem ou ambientes altamente corrosivos (por exemplo, marinhos ou ácidos). Para tais aplicações, considere as classes 304 ou 316.

Composição Química (ASTM A276 / AISI 416)

| Elemento | Conteúdo (%) |

|---|---|

| Carbono (C) | ≤ 0.15 |

| Manganês (Mn) | ≤ 1.00 |

| Fósforo (P) | ≤ 0.040 |

| Enxofre (S) | ≥ 0.15 |

| Silício (Si) | ≤ 1.00 |

| Cromo (Cr) | 12.0–14.0 |

| Níquel (Ni) | ≤ 0.60 |

| Ferro (Fe) | Equilíbrio |

O teor elevado de enxofre (mínimo de 0,15%) é fundamental para seu comportamento de usinagem livre, formando inclusões de sulfeto de manganês que atuam como quebra-cavacos durante o corte.

Propriedades Mecânicas (Condição Recozida)

| Propriedade | Valor |

|---|---|

| Resistência à Tração | 515–725 MPa (75–105 ksi) |

| Limite de Escoamento (0,2% de deslocamento) | 275–415 MPa (40–60 ksi) |

| Alongamento na Ruptura | 20–25% |

| Dureza (HB) | 183 máx. |

| Densidade | 7,74 g/cm³ |

| Ponto de Fusão | 1.450–1.510°C (2.642–2.750°F) |

Após o tratamento térmico (por exemplo, têmpera a 980–1.010°C + revenido a 150–650°C), a dureza pode atingir 25–45 HRC com aumentos correspondentes na resistência.

Propriedades Físicas

| Propriedade | Valor |

|---|---|

| Condutividade Térmica | 24,9 W/m·K @ 100°C |

| Resistividade Elétrica | 0,57 µΩ·m |

| Capacidade de Calor Específica | 460 J/kg·K @ 20°C |

| Coeficiente de Expansão Térmica | 10,0 µm/m·°C (20–100°C) |

| Permeabilidade Magnética | Ferromagnético (magnético) |

Sua natureza magnética torna o 416 adequado para aplicações que exigem resposta magnética, ao contrário das classes austeníticas (por exemplo, 304).

Comparação de Usinabilidade

| Classe de Aço Inoxidável | Usinabilidade Relativa (% do aço B1112) |

|---|---|

| 416 | 85% |

| 303 | 78% |

| 304 | 45% |

| 17-4 PH | 40% |

Fonte: ASM International, Project 7000 Stainless Data Sheets

Esta usinabilidade superior se traduz em:

- Até 30% mais rápido nas velocidades de corte

- Consumo de energia reduzido

- Vida útil mais longa da pastilha/ferramenta

- Melhor acabamento superficial nas peças usinadas

Especificações Disponíveis

| Parâmetro | Opções |

|---|---|

| Espessura | 0,5 mm a 25,0 mm (retificado com precisão) |

| Largura | 100 mm a 1.500 mm |

| Comprimento | 500 mm a 6.000 mm (corte sob medida) |

| Acabamento de Superfície | Retificado (Ra 0,4–0,8 µm), BA ou 2B |

| Condição de Têmpera | Recozido, Endurecido e Temperado (H&T) |

| Padrões em Conformidade | ASTM A240, ASTM A276, AISI 416, UNS S41600, JIS SUS416 |

| Embalagem | Papel VCI, caixas de madeira, embalagem à prova de umidade |

Todas as chapas são testadas por ultrassom para detectar defeitos internos e certificadas com Relatórios de Teste de Fábrica (MTRs) por EN 10204 3.1.

Diretrizes de Tratamento Térmico

| Processo | Faixa de Temperatura | Método de Resfriamento | Propriedades Resultantes |

|---|---|---|---|

| Recozimento | 815–900°C | Resfriamento ao ar | Condição macia e usinável (HB ≤ 183) |

| Endurecimento | 980–1.010°C | Têmpera em óleo ou ar | Estrutura martensítica, alta dureza |

| Revenido | 150–650°C (ajustar conforme as necessidades de resistência/tenacidade) | Resfriamento ao ar | Resistência e ductilidade otimizadas |

Evite a exposição prolongada acima de 425°C em serviço para evitar fragilização.

Desempenho de Resistência à Corrosão

Embora não seja tão resistente à corrosão quanto 304 ou 316, o 416 tem um bom desempenho em:

- Ambientes internos secos

- Condições atmosféricas amenas

- Sistemas de água doce

- Exposições químicas não cloretadas

Limitações:

- Má resistência a cloretos, ácidos e névoa salina

- Não adequado para aplicações marítimas ou costeiras

- Evite o uso em ambientes ácidos de qualidade alimentar (por exemplo, vinagre, cítricos)

Para maior resistência à corrosão, mantendo uma boa usinabilidade, considere as alternativas 416Se (modificado com selênio) ou 430F.

Por que escolher nossas chapas 416 retificadas com precisão?

✅ Qualidade consistente: Cada lote atende aos padrões ASTM/ISO com rastreabilidade total.

✅ Tolerâncias apertadas: Tolerância de espessura ±0,02 mm alcançável para aplicações críticas.

✅ Cadeia de suprimentos global: Estoque disponível na América do Norte, Europa e Ásia.

✅ Suporte técnico: Assistência de engenharia para seleção e processamento de materiais.

✅ Eco-consciente: Reciclável (conteúdo reciclado >90% possível); em conformidade com RoHS e REACH.

✅ Tolerâncias apertadas: Tolerância de espessura ±0,02 mm alcançável para aplicações críticas.

✅ Cadeia de suprimentos global: Estoque disponível na América do Norte, Europa e Ásia.

✅ Suporte técnico: Assistência de engenharia para seleção e processamento de materiais.

✅ Eco-consciente: Reciclável (conteúdo reciclado >90% possível); em conformidade com RoHS e REACH.

- Chapa de aço inoxidável 416 retificada com precisão

- Chapa de aço inoxidável de alta usinabilidade

- Aço inoxidável martensítico de usinagem livre

- Aço plano retificado AISI 416

- Fornecedor de chapa de aço inoxidável SUS416

- Aço inoxidável 416 para usinagem CNC

- Aço usinável resistente à corrosão

- Chapa de aço inoxidável ASTM A240 416

Informações para Pedido

Entre em contato com nossa equipe de vendas para:

- Dimensões e acabamentos de superfície personalizados

- Estoque tratado termicamente ou pré-endurecido

- Certificações (MTR, RoHS, DFARS)

- Descontos por volume (MOQ: 50 kg)

Prazo de entrega: 3 a 7 dias para tamanhos padrão; 2 a 3 semanas para pedidos personalizados.

Produtos recomendados