-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

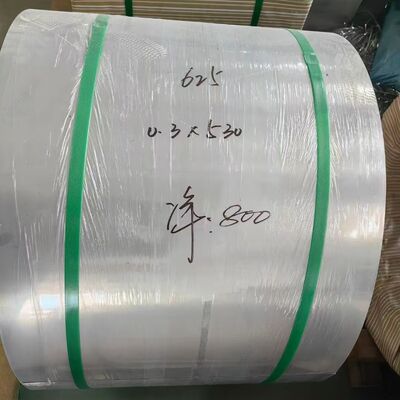

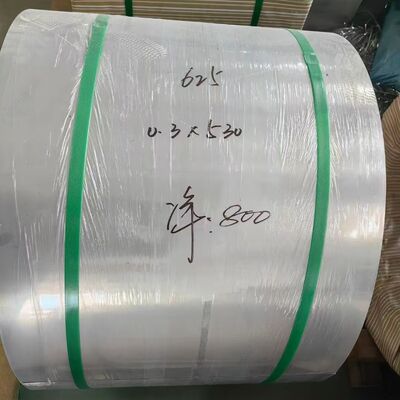

Precision Cold-Rolled UNS N06625 Nickel Alloy Strip for Aerospace and Chemical Processing

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 600,625,718,800,c276,400.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 22 - 30 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

| Products | Nickel Alloy Sheet & Plate | Grade | 600,625,718,800,c276,400.etc |

|---|---|---|---|

| Thickness | 0.05 - 30.0mm | Width | Custom Slit Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B BA |

| Highlight | Precision cold-rolled nickel alloy strip,UNS N06625 aerospace alloy strip,Nickel alloy strip for chemical processing |

||

Precision Cold-Rolled UNS N06625 Nickel Alloy Strip for Aerospace and Chemical Processing

Products Specification

| Products Name | UNS N06625 Nickel Alloy Strips |

| Thickness | 0.05 - 3.0mm |

| Width | within 1219mm |

| Surface | 2B BA |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Main Grade | Hastelloy C22 C4 X C276 G35 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 617 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

Precision Cold-Rolled UNS N06625 Nickel Alloy Strip for Aerospace and Chemical Processing

Product Overview

The precision cold-rolled UNS N06625 nickel alloy strip is a high-integrity, engineered material specifically designed to meet the exacting demands of aerospace engineering and chemical processing industries. Known commercially as Inconel® 625, this nickel-chromium-molybdenum-niobium superalloy delivers exceptional resistance to corrosion, oxidation, and mechanical degradation across extreme temperature ranges—from cryogenic conditions up to 982°C (1800°F).

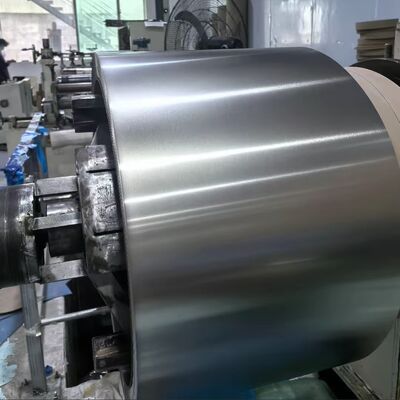

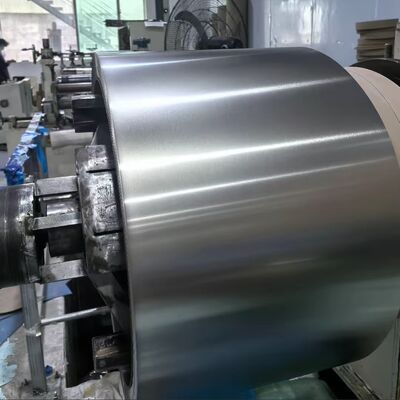

Manufactured through advanced cold-rolling techniques, this precision strip offers tight dimensional tolerances, uniform mechanical properties, and superior surface finish, making it ideal for mission-critical components such as turbine seals, sensor housings, heat exchanger plates, and chemical reactor linings.

Why Precision Cold-Rolled?

Cold rolling enhances the alloy’s strength through work hardening while maintaining excellent ductility and surface quality. Unlike hot-rolled products, cold-rolled UNS N06625 strip features:

- Thickness tolerances as tight as ±0.005 mm

- Smooth, defect-free surfaces suitable for welding, plating, or direct use

- Consistent grain structure for predictable performance in fatigue-prone applications

- Customizable tempers (annealed, half-hard, full-hard) to match specific design requirements

This level of precision is essential in aerospace and chemical sectors where component failure can lead to catastrophic consequences.

Key Advantages

| Feature | Benefit |

|---|---|

| Solid-solution strengthening (via Mo & Nb) | High strength without heat treatment |

| Chromium oxide layer formation | Resists oxidation and scaling up to 1095°C |

| Molybdenum content (~9%) | Exceptional resistance to pitting and crevice corrosion in chloride environments |

| Niobium stabilization | Prevents sensitization during welding; no post-weld annealing needed |

| Non-magnetic properties | Ideal for avionics, sensors, and instrumentation |

Chemical Composition (UNS N06625 – ASTM B443 / AMS 5599)

| Element | Content (%) |

|---|---|

| Nickel (Ni) | Balance (>58%) |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium + Tantalum (Nb+Ta) | 3.15 – 4.15 |

| Iron (Fe) | ≤ 5.0 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.015 |

| Aluminum (Al) + Titanium (Ti) | ≤ 0.80 total |

All values comply with international standards including ASTM, ASME, AMS, and ISO.

Mechanical Properties (Typical – Annealed Condition)

| Property | Value |

|---|---|

| Tensile Strength | ≥ 830 MPa (120 ksi) |

| Yield Strength (0.2% offset) | ≥ 415 MPa (60 ksi) |

| Elongation | ≥ 30% |

| Hardness (Rockwell B) | ≤ 100 HRB |

| Modulus of Elasticity | 207 GPa (30 × 10⁶ psi) |

Properties can be tailored through controlled cold work (e.g., half-hard temper: tensile strength up to 1100 MPa).

Available Dimensions & Finishes

| Parameter | Range |

|---|---|

| Thickness | 0.025 mm to 3.0 mm (custom down to 0.01 mm for foil-grade) |

| Width | 5 mm to 610 mm (slit-to-width available) |

| Length | In coils (up to 500 kg) or cut-to-length sheets |

| Surface Finish | 2B, BA (Bright Annealed), Matte, Brushed, or Custom |

| Temper | Annealed (soft), ¼ Hard, ½ Hard, Full Hard, Spring Temper |

All strips are ultrasonically cleaned and packaged in moisture-barrier VCI film for shipment.

Industry-Specific Applications

✈️ Aerospace

- Jet engine combustion chambers and afterburner components

- Exhaust nozzles and thrust reverser systems

- Seals, bellows, and fasteners in high-cycle fatigue environments

- Avionic shielding tapes requiring non-magnetic properties

⚗️ Chemical Processing

- Linings for reactors handling HCl, H₂SO₄, and wet chlorine

- Heat exchanger plates in aggressive media

- Piping gaskets and expansion joints in sour service (NACE MR0175 compliant)

- Electrolysis anodes and cathode baskets