-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

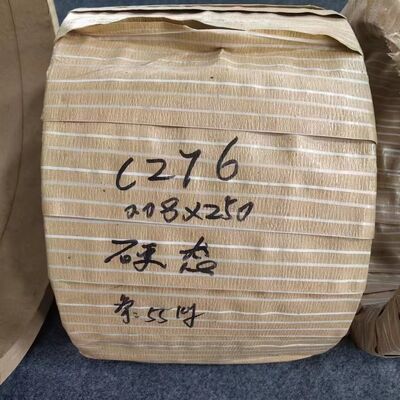

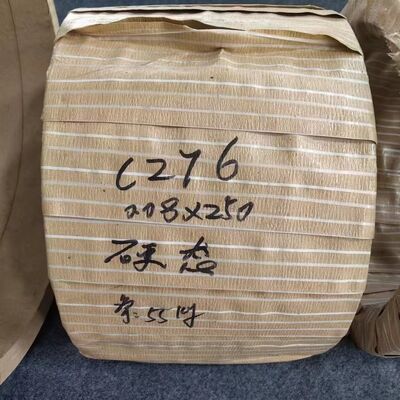

UNS N06625 Inconel 625 Nickel Alloy Strip High-Temperature Corrosion-Resistant Steel Tape

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | 600,625,718,800,c276,400.etc |

| Minimum Order Quantity | 500 kgs |

| Price | 22 - 30 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 3 Ton per week |

| Products | Nickel Alloy Sheet & Plate | Grade | 600,625,718,800,c276,400.etc |

|---|---|---|---|

| Thickness | 0.05 - 30.0mm | Width | Custom Slit Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | 2B BA |

| Highlight | Inconel 625 nickel alloy strip,High-temperature corrosion-resistant steel tape,UNS N06625 nickel alloy strip |

||

UNS N06625 Inconel 625 Nickel Alloy Strip High-Temperature Corrosion-Resistant Steel Tape

Products Specification

| Products Name | UNS N06625 Nickel Alloy Strips |

| Thickness | 0.05 - 3.0mm |

| Width | within 1219mm |

| Surface | 2B BA |

| MOQ | 50 kgs |

| Service | Cutting, Surface Finishing |

| Packing | Waterproof paper and wooden pallets |

| Loading Port | Shanghai Port |

| Price term | FOB CFR CIF EXW |

| Payment term | 30% TT in advance , 70% TT balance against copy of B/L |

| Main Grade | Hastelloy C22 C4 X C276 G35 |

| Monel 400 K500 | |

| Incoloy 800 800H 800HT 825 925 | |

| Inconel 600 601 617 625 716 718 | |

| Stainless Steel Grade | 201 202 301 304L 309S 310S 316L 316Ti 317L 321 347 409L 410 410S 420J1 420J2 430 431 436L 439 440A/B/C 441 443 444 2205 2507 904L 254SMO 253MA |

UNS N06625 Inconel 625 Nickel Alloy Strip – High-Temperature Corrosion-Resistant Steel Tape

Overview

UNS N06625, commonly known as Inconel 625, is a high-performance nickel-chromium-molybdenum-niobium alloy renowned for its exceptional resistance to corrosion, oxidation, and mechanical degradation across a wide temperature range—from cryogenic conditions up to 982°C (1800°F). The Inconel 625 nickel alloy strip, often referred to as high-temperature corrosion-resistant steel tape, is widely used in demanding industrial sectors such as aerospace, marine engineering, chemical processing, nuclear energy, and oil & gas.

This product information page provides comprehensive technical details, applications, specifications, and advantages of UNS N06625 nickel alloy strip, optimized for search visibility and user clarity in compliance with Google’s E-E-A-T (Experience, Expertise, Authoritativeness, Trustworthiness) guidelines.

Key Features of Inconel 625 Strip

- Outstanding corrosion resistance in both oxidizing and reducing environments

- Excellent resistance to pitting, crevice corrosion, and stress-corrosion cracking

- High strength and toughness from cryogenic to elevated temperatures

- Superior oxidation resistance up to 1095°C (2000°F) due to protective Cr₂O₃ layer

- Good weldability and fabricability without post-weld heat treatment

- Non-magnetic in annealed condition—ideal for sensitive instrumentation

Chemical Composition (Weight %)

| Element | Content (%) |

|---|---|

| Nickel (Ni) | Balance (>58%) |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium + Tantalum (Nb+Ta) | 3.15 – 4.15 |

| Iron (Fe) | ≤ 5.0 |

| Carbon (C) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.50 |

| Silicon (Si) | ≤ 0.50 |

| Sulfur (S) | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.015 |

| Aluminum (Al) | ≤ 0.40 |

| Titanium (Ti) | ≤ 0.40 |

| Cobalt (Co) | ≤ 1.0 |

Note: Composition conforms to ASTM B443, AMS 5599, and UNS N06625 standards.

Physical Properties

| Property | Value |

|---|---|

| Density | 8.44 g/cm³ (0.305 lb/in³) |

| Melting Range | 1290–1350°C (2350–2460°F) |

| Thermal Conductivity (100°C) | 9.8 W/m·K |

| Specific Heat (20–100°C) | 410 J/kg·K |

| Electrical Resistivity | 1.29 µΩ·m |

| Mean Coefficient of Thermal Expansion (20–100°C) | 12.8 × 10⁻⁶/°C |

Mechanical Properties (Typical, Annealed Condition)

| Property | Value (Cold-Rolled Strip) |

|---|---|

| Tensile Strength | ≥ 830 MPa (120 ksi) |

| Yield Strength (0.2% offset) | ≥ 415 MPa (60 ksi) |

| Elongation | ≥ 30% |

| Hardness (HB) | ≤ 220 |

Values may vary slightly based on temper, thickness, and processing method.

Product Forms & Dimensions

The Inconel 625 nickel alloy strip is available in multiple tempers and precision dimensions to meet diverse engineering needs:

| Form Type | Thickness Range | Width Range | Temper Options |

|---|---|---|---|

| Cold-Rolled Strip | 0.05 mm – 3.0 mm | 5 mm – 600 mm | Annealed, Half-Hard, Full-Hard |

| Precision Tape | 0.025 mm – 1.5 mm | Custom widths | Bright Annealed, Spring Temper |

| Foil | < 0.05 mm | Up to 300 mm | Soft Annealed |

Custom slitting, cutting-to-length, and surface finishes (e.g., 2B, BA, matte, bright) are available upon request.

Standards & Equivalents

| Standard System | Designation |

|---|---|

| UNS | N06625 |

| ASTM | B443, B572, B704 |

| ASME | SB-443 |

| AMS | 5599, 5666 |

| DIN / EN | 2.4856 (NiCr22Mo9Nb) |

| ISO | NW 6625 |

| JIS | NCF 625 |

| GB (China) | GH3625 |

Applications

Thanks to its unique combination of properties, Inconel 625 strip is critical in the following high-stakes applications:

- Aerospace: Jet engine exhaust systems, thrust reversers, combustion liners

- Marine: Seawater piping, propeller blades, submarine components

- Chemical Processing: Reactors, heat exchangers, acid handling equipment

- Oil & Gas: Downhole instrumentation, sour gas service components

- Nuclear: Control rod drive mechanisms, reactor core internals

- Pollution Control: Flue gas desulfurization (FGD) systems

- Electronics: High-reliability connectors, shielding tapes

Its ability to resist chloride-induced stress corrosion cracking makes it especially valuable in offshore and coastal installations.

Why Choose Inconel 625 Strip Over Alternatives?

Compared to stainless steels (e.g., 316L) or even other nickel alloys like Inconel 600 or Hastelloy C-276, Inconel 625 offers a superior balance of:

- Higher strength without precipitation hardening (due to solid-solution strengthening by Mo and Nb)

- Better fabricability than C-276 while maintaining comparable corrosion resistance

- Longer service life in cyclic thermal environments thanks to stable oxide scale adhesion

- No need for post-weld heat treatment, reducing fabrication costs

This makes it a cost-effective solution over the lifecycle of critical components.

Manufacturing & Quality Assurance

Reputable suppliers produce UNS N06625 nickel alloy strip using vacuum induction melting (VIM) or electric arc remelting (VAR) to ensure ultra-low impurity levels. Each batch undergoes rigorous testing, including:

- Spectrometric chemical analysis

- Tensile and hardness testing

- Ultrasonic or eddy current inspection (for defect detection)

- Intergranular corrosion testing per ASTM G28

- Certification to EN 10204 3.1 or 3.2 standards

Full traceability from melt to final product is maintained for quality-critical industries.

Ordering Information

When requesting a quote or placing an order, please specify:

- Material Grade: UNS N06625 / Inconel 625

- Form: Strip, tape, or foil

- Dimensions: Thickness × Width × Length (or coil weight)

- Temper & Surface Finish

- Applicable Standard: e.g., ASTM B443, AMS 5599

- Quantity & Delivery Requirements

Lead times typically range from 2 to 8 weeks, depending on stock availability and customization needs.

Conclusion

The UNS N06625 Inconel 625 nickel alloy strip stands as a benchmark material for extreme environments where failure is not an option. Its unmatched blend of corrosion resistance, high-temperature stability, and mechanical reliability ensures safety, efficiency, and longevity in the world’s most challenging applications. Whether you're designing next-generation aerospace systems or building corrosion-proof chemical plants, Inconel 625 strip delivers performance you can trust.

For engineers, procurement specialists, and manufacturers seeking a dependable, high-integrity material solution, Inconel 625 remains the gold standard in nickel-based alloy strips.

UNS N06625 strip, Inconel 625 nickel alloy tape, high-temperature corrosion-resistant steel tape, nickel alloy strip supplier, Inconel 625 chemical composition, ASTM B443 strip, corrosion-resistant metal tape, 2.4856 foil, marine-grade nickel strip, aerospace alloy tape.

![]()

![]()

![]()

![]()