-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

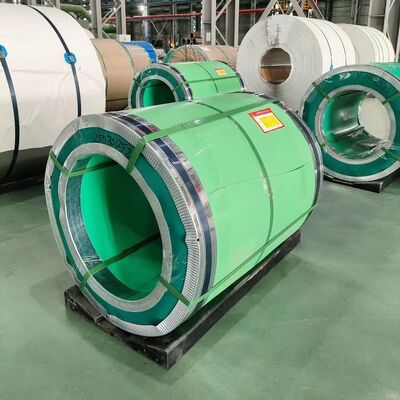

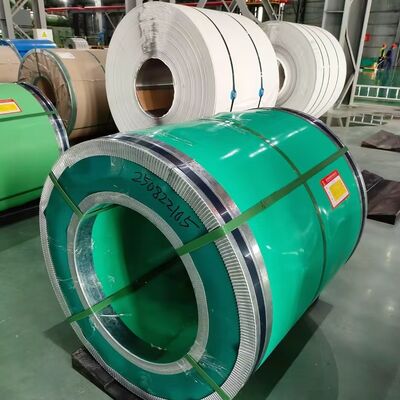

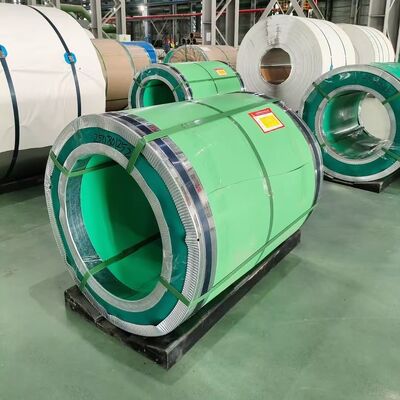

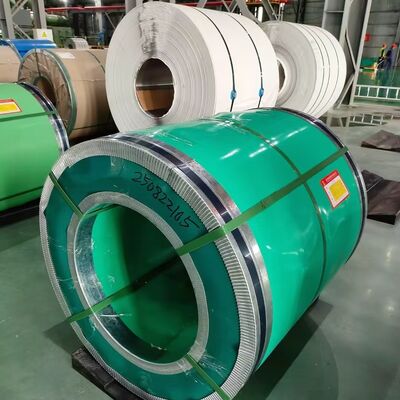

309S Stainless Steel Sheet Coil Thickness 0.6 - 3.0mm Cold Rolled 4ft*8ft SS Sheet Heat Resistant for Boiler

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Sheet | Grade | 309S |

|---|---|---|---|

| Thickness | 0.6 - 16.0mm | Tech | Cold Rolled,hot Rolled , Forged |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | 2B BA NO.1 |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | 309S stainless steel sheet 4ftx8ft,heat resistant stainless steel coil,cold rolled SS sheet boiler |

||

309S Stainless Steel Sheet Coil Thickness 0.6 - 3.0mm Cold Rolled 4ft*8ft SS Sheet Heat Resistant for Boiler

Stainless Steel Sheet Specifications

| Name | 309S stainless steel sheet |

| Our Grade |

200 Series: 201 202 300 Series: 301 304,304L,304H,309S,310S,314,316L,316Ti,316H,316LN,317L,321,329,347 400 Series: 409L,410,410S,416,420,430,431,436L.439,441,443,444,445,446 Super Stainless Steel: 904L,926,254SMO,654SMO,15-5PH,17-4PH,17-7PH.etc Nickel Alloy: C276, C22,G35,Alloy X,Monel 400,K500,Inconel 600,601,617,625,718,Incoloy 800,800H,800HT,825.etc |

| Technique | Hot Rolled, Cold Rolled,Forged |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

| Thickness | 0.1 – 80.0mm |

| Width range | 10mm – 2000mm |

| Length | Customized |

| Finish | 2B, BA, No.4, 8k, Brushed,Hairline,PVD Coating,Sandblasted |

| Service | Laser Cutting, Bending |

| Sample | Available |

Product Overview

309S stainless steel sheet coil is a high-alloy austenitic stainless steel engineered for exceptional performance in elevated-temperature environments. With a thickness range of 0.6 mm to 3.0 mm, cold-rolled finish, and standard sheet dimensions of 4 feet by 8 feet (1219 mm × 2438 mm), this material is ideal for demanding applications such as boilers, heat exchangers, furnace components, exhaust systems, and thermal processing equipment.

The “S” in 309S denotes a low carbon content (≤0.08%), which significantly reduces the risk of carbide precipitation during welding—making it highly suitable for welded fabrications without requiring post-weld annealing. This feature, combined with its outstanding oxidation resistance up to 980°C (1796°F), positions 309S as a preferred choice in industries where reliability under thermal stress is critical.

Manufactured to meet international standards including ASTM A240/A240M, ASME SA-240, and UNS S30908, our 309S stainless steel sheets offer consistent mechanical properties, excellent formability, and long-term durability in harsh operating conditions.

Key Features & Benefits

- ✅ High-Temperature Resistance: Stable performance up to 980°C; short-term exposure possible up to 1095°C

- ✅ Superior Oxidation Resistance: Forms a protective chromium-rich oxide layer at high temperatures

- ✅ Low Carbon Content (309S variant): Minimizes sensitization and intergranular corrosion in welded zones

- ✅ Cold-Rolled Precision: Tight thickness tolerances, smooth surface finish, and enhanced strength

- ✅ Versatile Dimensions: Standard 4ft × 8ft sheets (custom cutting available)

- ✅ Widely Compatible: Meets global material standards (AISI, UNS, EN, JIS, GB)

- ✅ Corrosion Resistance: Effective against sulfidation, carburization, and moderate acid environments

Typical Chemical Composition (ASTM A240 / UNS S30908)

| Element | Content (%) |

|---|---|

| Carbon (C) | ≤ 0.08 |

| Manganese (Mn) | ≤ 2.00 |

| Silicon (Si) | ≤ 0.75 |

| Phosphorus (P) | ≤ 0.045 |

| Sulfur (S) | ≤ 0.030 |

| Chromium (Cr) | 22.0 – 24.0 |

| Nickel (Ni) | 12.0 – 15.0 |

| Iron (Fe) | Balance |

Note: Exact composition may vary slightly based on production batch and customer specifications.

Mechanical Properties (Typical Values, Annealed Condition)

| Property | Value |

|---|---|

| Tensile Strength | ≥ 520 MPa (75,000 psi) |

| Yield Strength (0.2% offset) | ≥ 205 MPa (30,000 psi) |

| Elongation in 50 mm | ≥ 40% |

| Hardness (Rockwell B) | ≤ 95 HRB |

| Density | 7.9 g/cm³ |

| Melting Range | 1400–1450°C (2550–2650°F) |

These properties ensure structural integrity even under cyclic thermal loading—essential for boiler shells, burner nozzles, and radiant tubes.

Physical & Thermal Characteristics

| Property | Value |

|---|---|

| Thermal Conductivity (100°C) | 13.3 W/m·K |

| Specific Heat (0–100°C) | 500 J/kg·K |

| Electrical Resistivity | 720 nΩ·m |

| Coefficient of Thermal Expansion (20–100°C) | 14.7 µm/m·°C |

| Modulus of Elasticity | 190 GPa |

The relatively low thermal conductivity and high expansion coefficient must be considered during design to accommodate thermal stresses.

Available Specifications

| Parameter | Details |

|---|---|

| Grade | AISI 309S / UNS S30908 / EN 1.4833 / JIS SUS309S / GB 06Cr23Ni13 |

| Form | Cold Rolled Sheet / Coil |

| Thickness Range | 0.6 mm – 3.0 mm (custom tolerances ±0.03 mm available) |

| Width | Up to 1550 mm (standard coil); cut-to-size sheets: 1219 mm (4 ft) |

| Length | 2438 mm (8 ft) standard; custom lengths upon request |

| Surface Finish | 2B (standard), BA, No.4, HL (brushed), or custom finishes |

| Edge Type | Slit edge or mill edge |

| Packaging | Waterproof paper + PVC film + wooden pallets (export-ready) |

| Standards | ASTM A240, ASME SA-240, ISO 9001:2015 certified production |

Why Choose 309S Over Other Grades?

While 304 and 316 stainless steels are common for general corrosion resistance, they lack the high-temperature stability required for boiler systems. In contrast:

- 309S vs. 304: 309S contains nearly double the chromium and ~3× more nickel, drastically improving oxidation resistance above 600°C.

- 309S vs. 310S: Though 310S offers higher temperature capability (up to 1150°C), 309S provides a cost-effective balance for applications below 1000°C with excellent weldability.

- 309S vs. 309: The “S” version’s lower carbon prevents weld decay—critical for pressure vessels like boilers governed by ASME codes.

Common Industrial Applications

| Industry | Application Examples |

|---|---|

| Power Generation | Boiler tubes, superheater supports, flue gas ducts |

| Chemical Processing | Reactor linings, sulfur recovery units, nitric acid handling |

| Metallurgy | Annealing covers, sintering trays, radiant tubes |

| Food & Beverage | High-temp ovens, sterilization chambers (compatible with citric/acetic acids) |

| Automotive | Exhaust manifolds, catalytic converter housings |

| Waste Incineration | Combustion chambers, ash handling systems |

Note: Not recommended for chloride-rich environments due to potential stress corrosion cracking.

Quality Assurance & Certification

All 309S stainless steel sheets are produced under strict ISO 9001:2015 quality management systems. Each batch undergoes:

- Spectrometric chemical analysis

- Tensile and hardness testing

- Ultrasonic or eddy current inspection (optional)

- Surface quality verification (per ASTM A480)

- Mill Test Report (MTR) provided with EN 10204 3.1 certification

We also support third-party inspections (e.g., SGS, BV, TÜV) for critical projects.

Ordering Information

To place an order or request a quote, please provide the following details:

- Grade: 309S (UNS S30908)

- Dimensions: Thickness (e.g., 1.5 mm), Width (e.g., 1219 mm), Length (e.g., 2438 mm)

- Quantity: In kg, tons, or number of sheets

- Surface Finish: 2B (default), BA, No.4, etc.

- Certification Requirements: MTR, 3.1 certificate, PMI test, etc.

- Delivery Terms: FOB, CIF, or EXW; destination port/city

Lead time: Typically 7–15 days for stock items; 25–35 days for mill production.

Frequently Asked Questions (FAQ)

Q: Can 309S stainless steel be used in wet, acidic environments?

A: It performs well in nitric and organic acids at elevated temperatures but is not suitable for hydrochloric or sulfuric acid service. Avoid chloride concentrations >200 ppm.

Q: Is 309S magnetic?

A: Generally non-magnetic in annealed condition. Slight magnetism may develop after cold working.

Q: What’s the difference between hot-rolled and cold-rolled 309S?

A: Cold-rolled sheets offer better surface finish, tighter tolerances, and higher strength—ideal for precision parts. Hot-rolled is used for thicker plates (>3 mm).

Q: Can you laser-cut or CNC-machine 309S sheets?

A: Yes. We offer value-added services including laser cutting, waterjet cutting, bending, punching, and welding.

Conclusion

For engineers and procurement professionals seeking a reliable, high-performance stainless steel for boiler and high-temperature industrial applications, 309S cold-rolled sheet (0.6–3.0 mm, 4ft×8ft) delivers the perfect blend of heat resistance, weldability, and corrosion protection. Backed by rigorous quality control and global material standards, this grade ensures safety, efficiency, and longevity in the most thermally aggressive environments.

Contact us today for competitive pricing, technical data sheets, or sample requests. We serve clients worldwide with fast logistics and customized solutions.

309S stainless steel sheet, cold rolled 309S coil, heat resistant stainless steel for boiler, 0.6mm 309S sheet, 4x8 stainless steel sheet 309S, UNS S30908 plate, high temperature stainless steel coil, ASTM A240 309S, boiler grade stainless steel, SUS309S sheet supplier.

![]()

![]()

![]()

![]()