-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Industrial Grade 316LN Stainless Steel Sheet High Strength & Resistance

| Products | Stainless Steel Plate | Grade | 304 304L 316L 316LN 310S 321 2205 2304 2507 904L 254SMO 630 .etc |

|---|---|---|---|

| Thickness | 1.0 - 80.0mm | Width | 1219mm 1500mm 1800mm |

| Surface | NO.1 2B | Brand | BAOSTEEL TISCO |

| Standard | ASTM EN DIN JIS GB | Loading Port | Shanghai Port |

| Highlight | 316LN stainless steel sheet high strength,industrial stainless steel plate corrosion resistance,316LN stainless steel plate with warranty |

||

Industrial Grade 316LN Stainless Steel Sheet High Strength & Resistance

Products Specification

| Products Name | 316LN Stainless Steel Plate Sheet |

| Main Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316LN,316TI, 317L, 321, 321H, 347,348, 409, 410, 410S, 420, 430, 441, 904L,630,631,254SMO,654SMO,253MA,2205,2304,2507.etc |

| Thickness | 0.6 - 80.0mm |

| Width | 1250mm,1500mm ,1800mm,2000mm, or custom other size as request |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Service | Laser Cutting |

| Form | Plate / sheet |

| Cutting Shape | Round , Square, or any special shape as request |

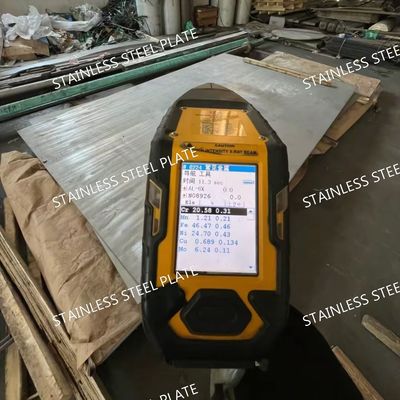

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Brand | TISCO, LISCO,BAOSTEEL , POSCO, JISCO |

Industrial Grade 316LN Stainless Steel Sheet: High Strength & Resistance

The 316LN stainless steel sheet is an industrial-grade material engineered for the most demanding environments. Combining exceptional strength, high corrosion resistance, and superior durability, 316LN is widely used across industries like chemical processing, marine engineering, and food manufacturing. This high-performance alloy is an enhanced version of the traditional 316 stainless steel, providing a level of protection and resilience that is unmatched by most other materials. Whether exposed to harsh chemicals, extreme temperatures, or corrosive environments, 316LN stainless steel sheet is designed to perform with consistency and longevity.

In this product information guide, we will explore the key benefits, properties, and applications of 316LN stainless steel sheets, along with a detailed comparison table to help you understand the features and performance metrics that set this material apart from other alloys.

What is 316LN Stainless Steel?

316LN is a low-nitrogen variant of 316 stainless steel. The addition of nitrogen improves the alloy's mechanical properties, such as tensile strength and stress corrosion cracking resistance. The material is composed mainly of iron, chromium, nickel, and molybdenum, with nitrogen being a significant element that enhances both strength and corrosion resistance. These characteristics make it ideal for heavy-duty applications, especially in environments where standard stainless steel would not hold up over time.

316LN stainless steel combines the best properties of the standard austenitic stainless steel group, which includes good weldability, formability, and resistance to oxidation and corrosion. It is particularly effective in chloride-rich environments and high-temperature applications.

Key Properties of 316LN Stainless Steel Sheet

| Property | Description |

|---|---|

| Corrosion Resistance | Superior resistance to corrosion in chloride environments (saltwater, acid). |

| Tensile Strength | High tensile strength, up to 80,000 psi, making it suitable for heavy-duty use. |

| Temperature Resistance | Can withstand temperatures up to 870°C (1600°F) without losing strength. |

| Weldability | Excellent weldability due to its low carbon content, preventing carbide formation. |

| Pitting Resistance | High resistance to pitting and crevice corrosion, ideal for marine environments. |

| Ductility and Formability | Easily fabricated into plates, sheets, and other shapes for industrial use. |

| Aesthetic Finish | Smooth, shiny surface that resists staining and maintains its appearance over time. |

| Hardness | High hardness, ensuring wear resistance and minimal surface damage. |

Why Choose 316LN Stainless Steel Sheets?

-

Corrosion Resistance in Harsh Environments

316LN stainless steel sheet excels in environments that are typically hostile to other materials. Whether in high-chloride environments like seawater or in acidic chemical applications, 316LN's resistance to pitting, crevice corrosion, and general corrosion makes it an excellent choice. The alloy’s molybdenum content (2-3%) enhances its ability to withstand corrosion from chlorine and other aggressive chemicals. -

High Strength and Durability

With the addition of nitrogen, 316LN stainless steel has increased tensile strength, making it highly durable under stress. It can withstand both mechanical wear and extreme environmental conditions without compromising its performance. The material is widely used in structural applications where strength and resilience are crucial, such as in bridges, industrial machinery, and offshore platforms. -

Temperature Resistance

The ability of 316LN to maintain its mechanical properties at high temperatures makes it indispensable in applications exposed to heat. It can endure environments with temperatures up to 870°C (1600°F) without significant loss of strength, making it suitable for use in furnaces, heat exchangers, and other high-temperature industrial systems. -

Excellent Fabrication and Weldability

The low carbon content of 316LN stainless steel reduces the risk of carbide precipitation during welding. This enhances the material's overall integrity and prevents corrosion at the weld joints. The alloy is easy to fabricate and can be processed into plates, sheets, and other forms to meet specific application needs. This is particularly valuable in industries that require custom shapes and sizes for unique installations. -

Aesthetic and Long-Lasting Finish

316LN stainless steel offers a smooth, polished surface that is resistant to tarnishing and discoloration over time. This makes it a preferred material for both functional and decorative uses, particularly in architectural applications where the appearance and longevity of the material are essential. -

Reduced Maintenance Costs

Due to its resistance to corrosion and wear, 316LN stainless steel sheets require less maintenance over time compared to other materials. This makes it cost-effective in the long run, particularly for industries with continuous operation or where uptime is critical.

Key Applications of 316LN Stainless Steel Sheets

316LN stainless steel sheets are used across a wide variety of industries, thanks to their versatility and strength. Some of the most common applications include:

1. Marine and Offshore Engineering

316LN stainless steel is often used in the marine industry due to its resistance to seawater corrosion. Marine-grade steel components such as hulls, offshore oil rigs, pipelines, and ship parts all benefit from the material's durability and resistance to chloride-induced corrosion.

2. Chemical Processing Plants

In chemical and petrochemical industries, the need for materials that resist corrosion from strong acids and chemicals is paramount. 316LN stainless steel sheets are commonly used in the manufacture of storage tanks, piping, and heat exchangers that handle corrosive chemicals.

3. Food and Pharmaceutical Manufacturing

Food and pharmaceutical processing equipment demand materials that maintain hygiene standards while resisting corrosion. 316LN stainless steel is frequently used in tanks, piping, and manufacturing machinery for these sectors due to its non-reactive properties and ease of cleaning.

4. Heat Exchanger Systems

The resistance of 316LN to both high temperatures and corrosion makes it ideal for use in heat exchangers, where the material is constantly exposed to thermal stresses and aggressive fluids. 316LN ensures that these systems operate efficiently over a long lifespan.

5. Architectural and Decorative Applications

316LN stainless steel is widely used in the construction and architectural industries, especially for exterior cladding, railings, and other decorative elements that require both aesthetic appeal and durability. The material's resistance to weathering and its smooth, shiny finish make it a top choice for buildings in coastal and urban environments.

6. Aerospace and Automotive Components

The aerospace industry uses 316LN stainless steel for engine components, exhaust systems, and other parts that are exposed to high temperatures and mechanical stresses. In the automotive industry, 316LN is utilized for parts that must withstand both high temperatures and corrosive substances.

How to Choose the Right 316LN Stainless Steel Sheet

Selecting the right 316LN stainless steel sheet for your project depends on several important factors, including:

-

Thickness: 316LN stainless steel sheets come in a range of thicknesses, from thin sheets for decorative uses to thicker plates for heavy-duty structural applications. The thickness of the sheet you choose should align with the requirements of the specific task.

-

Surface Finish: The surface finish of 316LN stainless steel is available in various forms, including mirror-polished, brushed, and matte finishes. Choose the finish based on aesthetic and functional needs. A mirror finish, for example, is often used for decorative applications, while a matte finish is preferred for industrial use.

-

Size and Customization: 316LN stainless steel sheets can be customized to meet specific size and dimensional requirements. Custom-cut sheets are essential for complex installations or components that need to fit precisely within a system or structure.

-

Certification and Standards: Ensure that the 316LN stainless steel sheet you choose complies with industry standards and certifications. Common standards include ASTM A240 and EN 10088, which ensure the material meets quality and safety specifications for various applications.

Benefits of Using 316LN Stainless Steel Sheets

-

Superior Performance in Extreme Conditions: 316LN stainless steel offers exceptional corrosion resistance and durability, making it ideal for industries dealing with harsh environments, including marine, chemical, and food sectors.

-

Enhanced Strength and Stress Resistance: With improved tensile strength, 316LN can handle higher mechanical loads and stresses, providing reliability and safety in structural and heavy-duty applications.

-

Long-Term Cost Effectiveness: Due to its long lifespan and minimal maintenance requirements, 316LN stainless steel sheets provide significant cost savings over time.

-

Ease of Fabrication and Customization: 316LN’s high formability and weldability allow for easy customization, ensuring that the material can be shaped to meet specific application requirements.

-

Aesthetic Value: In addition to its functional benefits, 316LN stainless steel maintains an attractive appearance over time, making it ideal for both industrial and decorative applications.

![]()

![]()

![]()

![]()