All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

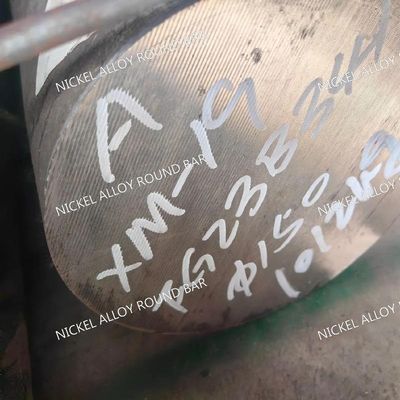

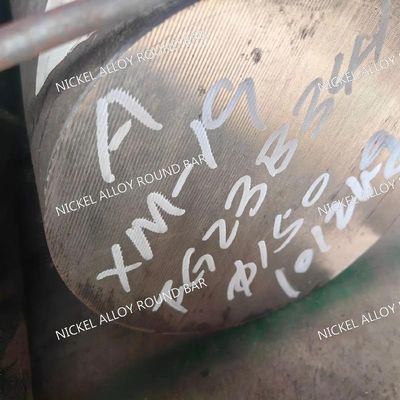

Nitronic 50 Alloy Round Bar XM-19 Stainless Steel Bar Nickel Alloy Round Rod Custom Cutting in Length

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Bar | Grade | XM-19 |

|---|---|---|---|

| Diameter | 5-300mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Bright,black |

| Highlight | Nitronic 50 alloy round bar,XM-19 stainless steel rod,custom cut nickel alloy rod |

||

Product Description

Nitronic 50 Alloy Round Bar XM-19 Stainless Steel Bar Nickel Alloy Round Rod Custom Cutting in Length

More Specification Informations

| Products Name | XM-19 Stainless Steel Bar |

| Diameter | 5-300mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Nitronic 50 Alloy Round Bar XM-19 Stainless Steel Bar Nickel Alloy Round Rod Custom Cutting in Length

Overview

XM-19 (also known as Nitronic 50, UNS S20910) round bar is a high-performance austenitic stainless steel product that integrates exceptional corrosion resistance and high strength—attributes unmatched by many commercial alloys in its class. Engineered to outperform conventional grades like 316 and 317, this nickel-alloy round rod delivers reliable performance across extreme temperatures and harsh chemical environments. We offer XM-19 round bars with flexible customization, including diameter options from 5mm to 250mm and custom length cutting to meet precise project requirements.

Chemical Composition (Weight %)

The superior properties of XM-19 round bar stem from its precisely balanced chemical formulation, as specified in industry standards:

| Element | Minimum (%) | Maximum (%) |

|---|---|---|

| Carbon (C) | — | 0.06 |

| Silicon (Si) | — | 1.00 |

| Manganese (Mn) | 4.00 | 6.00 |

| Phosphorus (P) | — | 0.040 |

| Sulfur (S) | — | 0.030 |

| Chromium (Cr) | 20.50 | 23.50 |

| Nickel (Ni) | 11.50 | 13.50 |

| Molybdenum (Mo) | 1.50 | 3.00 |

| Niobium (Nb) | 0.10 | 0.30 |

| Vanadium (V) | 0.10 | 0.30 |

| Nitrogen (N) | 0.20 | 0.40 |

| Iron (Fe) | Balance | Balance |

Source: ASTM standards and material technical data sheets

Mechanical Properties

XM-19 round bar exhibits outstanding mechanical performance in both annealed and cold-worked conditions, with strength levels far exceeding traditional austenitic stainless steels:

| Property | Condition | Value |

|---|---|---|

| Density | 25°C | 7.7–8.03 g/cm³ |

| Elastic Modulus | 25°C | 190–210 GPa |

| Tensile Strength | Annealed | ≥ 690 MPa |

| Tensile Strength | Oil-quenched, tempered at 425°C | 1158 MPa |

| Yield Strength (Rp0.2) | Annealed | ≥ 380 MPa |

| Yield Strength (Rp0.2) | Oil-quenched, tempered at 425°C | 1034 MPa |

| Elongation (A5) | Annealed | ≥ 35% |

| Elongation | Oil-quenched, tempered at 425°C | 15% |

| Brinell Hardness (HB) | Annealed | ≤ 241 |

| Brinell Hardness (HB) | Oil-quenched, tempered at 425°C | 335 |

| Poisson's Ratio | 25°C | 0.27–0.30 |

Notably, the high-strength (HS) variant of XM-19 achieves yield strength 3–4 times that of 316 stainless steel, while maintaining excellent ductility and toughness even at sub-zero temperatures. Additionally, it remains non-magnetic after cold working or low-temperature exposure—an advantage over many austenitic alloys.

Product Standards & Specifications

Our XM-19 round bars comply with global industry standards to ensure consistency and reliability:

- Primary Standards: ASTM A276, ASTM A479

- Material Certification: UNS S20910

- Industry Approvals: NACE MR0175/ISO 15156 (for sour service applications), NACE MR0103

- Manufacturing Processes: Hot-rolled, cold-drawn, and centerless ground (for precision finishes)

- Diameter Range: 5mm – 250mm (custom sizes available upon request)

- Standard Length: 1.5m – 12m (custom cutting to any length with ±1% tolerance)

- Quality Certification: ISO 9001, with material test reports (MTRs) provided for traceability

Key Applications

XM-19 round bar is the material of choice for industries requiring both corrosion resistance and high strength. Its versatility makes it suitable for:

- Oil & Gas/Petrochemical: Downhole rigging, pump shafts, valves, and fittings—outperforming 316 and 17-4 PH in sour environments

- Marine Engineering: Marine hardware, boat shafts, chains, and fasteners—resisting saltwater corrosion with double the yield strength of 316

- Chemical Processing: Heat exchanger components, reactor parts, and piping for handling aggressive chemicals

- Nuclear Industry: Nuclear fuel recycling equipment and structural components

- Food & Beverage: Processing machinery, screens, and wire cloth—meeting hygiene requirements

- Additional Sectors: Pulp and paper mills, textile machinery, medical equipment, and high-strength springs

Customization & Value-Added Services

We understand that every project has unique needs, so we offer comprehensive customization:

- Precision Cutting: Custom length cutting to your exact specifications (no minimum order for cutting services)

- Surface Finishes: Cold-drawn (mill finish), centerless ground, and polished options

- Packaging: Standard seaworthy packaging or custom packaging for international shipping

- Lead Time: 7–21 days, with sample availability for quality verification

- Supply Capacity: Up to 10,000 tons per month to support large-scale projects

Why Choose Our XM-19 Round Bar?

- Superior Corrosion Resistance: Outperforms 316/316L and 317/317L in general and crevice corrosion scenarios

- Unmatched Strength-to-Weight Ratio: Reduces component cross-sections while maintaining structural integrity

- Temperature Versatility: Reliable performance from cryogenic conditions to elevated temperatures

- Traceability: Full material certification and test reports for quality assurance

- Flexibility: Customizable sizes and finishes to minimize waste and installation time

![]()

![]()

![]()

![]()

Recommended Products