All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

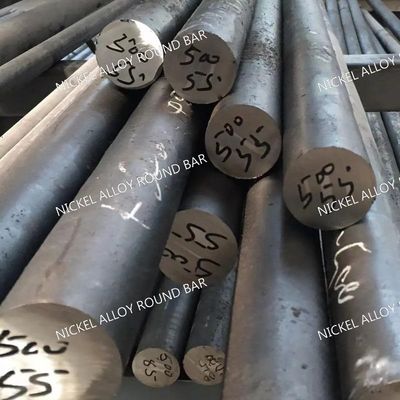

Nickel Alloy Round Bar Inconel Alloy, Incoloy Round Bar / Hastelloy Bars Custom Cutting into Any Length

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Nickel Alloy | Grade | 600 625 718 800 926 C276 C22 M400 K500.etc |

|---|---|---|---|

| Diameter | 3 - 350mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Bright,black |

| Highlight | Nickel Alloy Round Bar Inconel,Incoloy Round Bar custom cutting,Hastelloy Bars with warranty |

||

Product Description

Nickel Alloy Round Bar Inconel Alloy, Incoloy Round Bar / Hastelloy Bars Custom Cutting into Any Length

More Specification Informations

| Products Name | Nickel Alloy Round Bar |

| Grade |

|

| Diameter | 3 - 350mm |

| Length | custom cutting any length as request |

| Surface | bright, Black,pickling,polishing |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | Wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Nickel Alloy Round Bar Inconel Alloy, Incoloy Round Bar / Hastelloy Bars Custom Cutting into Any Length

Nickel alloy round bars represent a class of high-performance metallic materials engineered to deliver exceptional reliability in the most demanding industrial environments. Composed primarily of nickel blended with elements like chromium, molybdenum, iron, and copper, these round bars are manufactured through precision processes including forging, rolling, and cold drawing to ensure uniform structure and consistent performance. Available in customizable diameters from 3.17mm to 350mm and with flexible length options (standard 1m to 12m, plus custom cutting to any specified length), they cater to diverse manufacturing needs across industries requiring durability, corrosion resistance, and thermal stability. Whether for large-scale industrial equipment or precision components, our nickel alloy round bars—including Inconel, Incoloy, and Hastelloy variants—meet stringent quality benchmarks for critical applications.

Common Grades of Nickel Alloy Round Bars

Different nickel alloy grades are formulated to address specific environmental and mechanical requirements. Below are the most widely used grades and their core characteristics:

| Grade Category | Specific Grades | Key Composition & Traits |

|---|---|---|

| Pure Nickel | Nickel 200 (UNS N02200), Nickel 201 (UNS N02201) | 99%+ nickel content; exceptional corrosion resistance and thermal conductivity. Nickel 201 offers lower carbon for improved high-temperature performance. |

| Inconel | Inconel 600 (UNS N06600), Inconel 625 (UNS N06625), Inconel 718 | Nickel-chromium base; superior high-temperature strength (up to 1200°F) and oxidation resistance. Inconel 625 adds molybdenum for enhanced corrosion resistance. |

| Incoloy | Incoloy 800 (UNS N08800), Incoloy 825 (UNS N08825) | Nickel-iron-chromium alloy; balanced corrosion resistance and thermal stability. Ideal for sulfuric acid environments and thermal cycling applications. |

| Hastelloy | Hastelloy C276 (UNS N10276), Hastelloy C22 | Nickel-molybdenum-chromium blend; universal corrosion resistance in oxidizing/reducing acids, chlorides, and seawater. Resists pitting and stress corrosion cracking. |

| Monel | Monel 400 (UNS N04400) | Nickel-copper alloy; high strength and marine corrosion resistance. Used in saltwater and chemical processing environments. |

Industry Standards for Nickel Alloy Round Bars

Our nickel alloy round bars adhere to globally recognized standards to ensure consistency, safety, and compatibility with international manufacturing requirements:

- ASTM/ASME Standards: ASTM B160 (Nickel 200/201), ASTM B925 (general nickel alloy bars), ASME SB160 (seamless nickel alloy bars) — specify ,mechanical properties, and dimensional tolerances.

- Aerospace Specifications: AMS 5660 — sets rigorous standards for purity, heat treatment, and non-destructive testing for aerospace-grade applications.

- International Standards: DIN (Germany), JIS (Japan), BS (UK) — align with regional manufacturing norms for surface quality (Ra ≤ 1.6μm typical) and mechanical performance.

- Custom Certifications: Available with mill test reports (MTRs), NACE MR0175 compliance (for oil/gas), and FDA approval (for food processing) upon request.

Key Features of Nickel Alloy Round Bars

The superior performance of nickel alloy round bars stems from their unique material properties, making them indispensable for harsh-environment applications:

- Exceptional Corrosion Resistance: Nickel forms a dense, self-healing oxide layer that protects against acids (sulfuric, hydrochloric), alkalis, seawater, and chlorides. Hastelloy C276 and Incoloy 825 excel in the most aggressive chemical environments.

- High-Temperature Stability: Retains strength and oxidation resistance at extreme temperatures — Inconel 600 operates reliably up to 1453°C, while Nickel 200 maintains performance from cryogenic levels to 1200°F.

- Superior Mechanical Strength: High tensile strength (≥520MPa for Nickel 200) and toughness enable resistance to heavy loads and deformation. Forged variants offer enhanced structural integrity for high-stress components.

- Excellent Fabricability: Easy to machine, weld, and form into precision parts. Supports cold/hot working processes without compromising corrosion resistance or strength.

- Long-Term Durability: Resists dimensional changes and material fatigue, reducing maintenance costs and equipment downtime in critical applications.

Applications Across Industries

Nickel alloy round bars are integral to industries where material failure could lead to safety risks or operational disruption:

- Chemical Processing: Reactors, pipes, valves, and pump shafts — Hastelloy C276 and Nickel 200 withstand corrosive feedstocks and high-pressure reactions.

- Oil & Gas: Downhole tools, wellhead components, and offshore platforms — Monel 400 and Inconel 718 resist sulfide stress cracking and seawater corrosion.

- Aerospace & Defense: Turbine blades, engine components, and spacecraft parts — Inconel 625 and 718 handle extreme heat and mechanical stress.

- Marine Engineering: Ship propellers, offshore pipelines, and desalination equipment — UNS N02201 and Monel 400 prevent seawater-induced corrosion.

- Food & Pharmaceutical: Mixers, evaporators, and storage tanks — Nickel 200’s non-toxic, corrosion-resistant properties ensure compliance with food safety standards.

- Energy Sector: Nuclear control rods (Nickel 200), thermal power plant heat exchangers (Incoloy 800), and renewable energy components — withstands thermal cycling and aggressive coolants.

Custom Cutting & Value-Added Services

We offer precision custom cutting to any length (from 100mm to 6000mm+), with options for surface treatments including bright polishing, black oxide coating, and rough turning to match specific assembly requirements. Our state-of-the-art cutting equipment ensures clean, burr-free edges and tight dimensional tolerances, reducing post-processing time for manufacturers.

Whether you require small-batch precision cuts for aerospace components or large-volume orders for chemical plant infrastructure, our nickel alloy round bars deliver consistent performance backed by quality certifications. Contact us to discuss your grade, size, and certification needs.

![]()

![]()

![]()

![]()

Recommended Products