All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

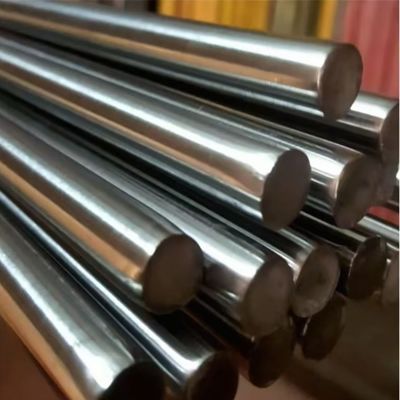

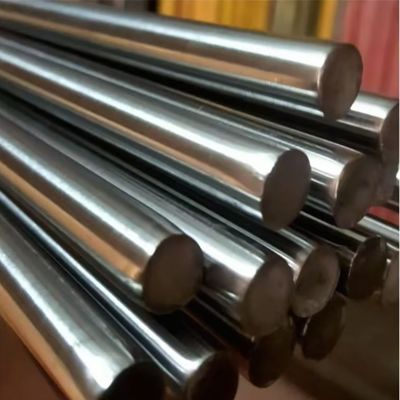

Incoloy 800H High Temperature & Corrosion Resistant Nickel-Iron-Chromium Alloy Bar

Product Details

| Products | Incoloy 800H Round Bar | Grade | Incoloy 800H |

|---|---|---|---|

| Diameter | 10 - 350mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | Incoloy 800H nickel alloy bar,high temperature resistant alloy bar,corrosion resistant nickel iron chromium bar |

||

Product Description

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725 Incoloy series: 800 800H 825 925 Hastelloy series: B,B2,B3,C,C-276,C-4,C-22 Pure: Ni200, Ni201 |

||

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

|

Width

|

1~1500mm

|

||

|

Square bar

|

Size: 4*4-100*100mm

|

||

|

Length

|

2m, 5.8m, 6m, or as required.

|

||

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

||

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

||

Incoloy 800H High Temperature & Corrosion Resistant Nickel-Iron-Chromium Alloy Bar

Incoloy 800H is a premium nickel-iron-chromium alloy bar engineered specifically to deliver exceptional performance in extreme high-temperature and corrosive environments. Its unique chemical composition and carefully optimized mechanical properties make it a top choice for critical applications across industries such as energy, petrochemical, and aerospace, where reliability and durability under harsh conditions are non-negotiable.

1. Chemical Composition

The precise chemical makeup of Incoloy 800H is the foundation of its superior performance. It adheres to strict industry standards to ensure consistency and quality, with the following typical composition (in weight percentage, wt%):

| Element | Content Range (wt%) | Role |

|---|---|---|

| Nickel (Ni) | 30.0 - 35.0 | Enhances high-temperature strength, ductility, and resistance to oxidation. |

| Iron (Fe) | Balance | Provides structural stability and acts as the base metal for the alloy. |

| Chromium (Cr) | 19.0 - 23.0 | Delivers excellent resistance to corrosion, oxidation, and carburization at high temperatures. |

| Carbon (C) | 0.05 - 0.10 | Improves creep strength and high-temperature structural integrity (a key distinction of the "H" grade). |

| Manganese (Mn) | ≤ 1.50 | Aids in deoxidation during manufacturing and enhances workability. |

| Silicon (Si) | ≤ 1.00 | Enhances oxidation resistance and supports alloy formation. |

| Copper (Cu) | ≤ 0.75 | Adds minor corrosion resistance benefits without compromising other properties. |

| Aluminum (Al) | 0.15 - 0.60 | Boosts oxidation resistance by forming a protective oxide layer at high temperatures. |

| Titanium (Ti) | 0.15 - 0.60 | Works with aluminum to stabilize the alloy and improve creep resistance; also enhances grain structure. |

| Phosphorus (P) | ≤ 0.030 | Controlled to minimize brittleness and maintain alloy purity. |

| Sulfur (S) | ≤ 0.015 | Strictly limited to prevent hot cracking and maintain mechanical integrity. |

2. Mechanical Properties

Incoloy 800H exhibits outstanding mechanical strength, especially at elevated temperatures, along with good ductility at room temperature. The following properties are typical for annealed alloy bars (tested at room temperature unless specified otherwise):

| Property | Test Standard | Typical Value |

|---|---|---|

| Tensile Strength (UTS) | ASTM B408 | ≥ 550 MPa (80 ksi) |

| Yield Strength (0.2% offset) | ASTM B408 | ≥ 240 MPa (35 ksi) |

| Elongation at Break | ASTM B408 | ≥ 30% (in 50 mm) |

| Hardness (Brinell) | ASTM E10 | ≤ 190 HB |

| Creep Rupture Strength | ASTM E139 | ≥ 100 MPa at 815°C (1500°F) for 10,000 hours |

| Modulus of Elasticity | - | 200 GPa (29 x 10⁶ psi) at room temperature; decreases slightly with increasing temperature. |

Note: Mechanical properties may vary slightly based on bar diameter, heat treatment process, and testing conditions. For high-temperature applications, consult detailed creep and stress-rupture data specific to your operating temperature range.

3. Product Standards

Incoloy 800H alloy bars are manufactured and inspected in compliance with globally recognized standards to ensure quality, safety, and interchangeability. Key standards include:

- ASTM B408: Standard Specification for Nickel-Iron-Chromium Alloy (Incoloy 800, 800H, 800HT) Bars and Rods

This is the primary standard for Incoloy 800H bars, covering chemical composition, mechanical properties, dimensional tolerances, and quality control requirements.

- ASME SB408: Boiler and Pressure Vessel Code (BPVC) Specification

Used for bars intended for pressure-containing components in boilers, reactors, and other pressure vessels.

- DIN EN 10095: European Standard for Heat-Resisting Steels and Alloys (for bars used in European markets).

- JIS G4902: Japanese Industrial Standard for Nickel-Based Heat-Resisting Alloys (relevant for Asia-Pacific applications).

All bars undergo rigorous testing, including chemical analysis (via X-ray fluorescence or optical emission spectroscopy), mechanical testing (tensile, hardness), and non-destructive testing (NDT) such as ultrasonic inspection to detect internal defects.

4. Product Advantages

Incoloy 800H stands out from other heat-resistant alloys due to its unique combination of benefits, making it ideal for demanding environments:

- Exceptional High-Temperature Stability: Maintains strength and structural integrity at temperatures up to 870°C (1600°F), with excellent creep and stress-rupture resistance—critical for long-term service in furnaces, reactors, and turbine components.

- Superior Corrosion & Oxidation Resistance: The chromium-aluminum-titanium content forms a dense, adherent oxide layer that protects the alloy from oxidation, sulfidation, and carburization in harsh media (e.g., flue gases, petrochemical streams, and high-temperature water).

- Excellent Ductility & Fabricability: Despite its high strength, Incoloy 800H offers good ductility at room temperature, enabling easy machining, welding, and forming into complex shapes (e.g., bolts, shafts, and heat exchanger tubesheets).

- Stable Chemical Composition: Strict control over carbon, titanium, and aluminum levels ensures consistent performance across batches, reducing the risk of premature failure in critical applications.

- Versatility: Performs well in both oxidizing and slightly reducing environments, making it suitable for a wide range of industries (energy, petrochemical, aerospace, and more).

5. Related Products

In addition to Incoloy 800H round bars, we offer a full range of Incoloy 800-series products to meet diverse application needs:

- Incoloy 800 Round Bars/Rods: Lower carbon content (0.03-0.10 wt%) than 800H, suitable for moderate-temperature corrosion-resistant applications (up to 760°C/1400°F).

- Incoloy 800HT Round Bars/Rods: Higher carbon, aluminum, and titanium content than 800H, optimized for ultra-high-temperature creep resistance (up to 980°C/1800°F).

- Incoloy 800H Sheets/Plates: Used for fabricating furnace liners, heat exchanger shells, and pressure vessel components.

- Incoloy 800H Pipes/Tubes: Ideal for high-temperature fluid transport in petrochemical plants and power generation facilities.

- Incoloy 800H Forgings: Custom-forged components (e.g., valves, flanges, and fittings) for heavy-duty industrial applications.

All related products adhere to the same strict quality standards as Incoloy 800H round bars, ensuring consistency across your entire project.

6. Applications

Incoloy 800H round bars are widely used in industries where high-temperature strength and corrosion resistance are critical. Key applications include:

- Energy Industry: Boiler tubes, superheater tubes, turbine blades, and nuclear reactor components (due to resistance to high-temperature water and radiation-induced corrosion).

- Petrochemical Industry: Reactor vessels, catalyst support grids, heat exchanger tubesheets, and piping for processing high-temperature hydrocarbons (resistant to sulfidation and carburization).

- Aerospace Industry: Engine components (e.g., combustion chambers, exhaust manifolds) and aircraft structural parts that operate at elevated temperatures.

- Metallurgical Industry: Furnace rollers, annealing 炉 fixtures, and heat treatment baskets (resistant to oxidation and thermal cycling).

- Chemical Industry: Pressure vessels, agitators, and valves for handling corrosive chemicals (e.g., acids, alkalis) at high temperatures.

Whether your application requires long-term creep resistance, corrosion protection, or structural stability in extreme heat, Incoloy 800H round bars deliver reliable performance you can trust.

![]()

![]()

![]()

![]()

Recommended Products