All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

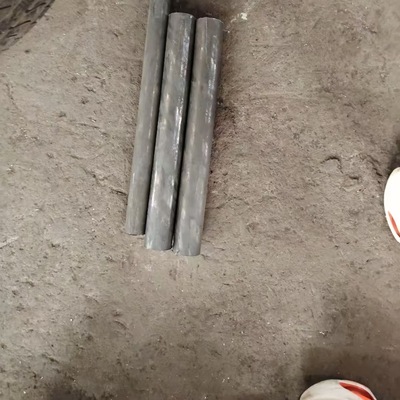

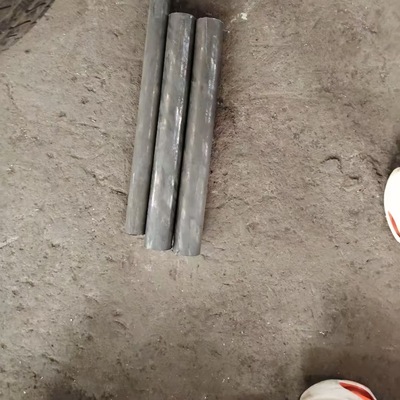

Precision-Machined Monel400 Round Steel with Excellent Strength Temperature Resistance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Monel 400 Round Bar | Grade | Monel 400 |

|---|---|---|---|

| Diameter | 10 - 350mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Black, Bright |

| Highlight | Monel400 round steel bar,Precision-machined nickel alloy,High-temperature resistant Monel400 steel |

||

Product Description

Precision-Machined Monel400 Round Steel with Excellent Strength Temperature Resistance

Products Specification

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

||

|

Grade

|

Monel series: 400 K500

Inconel series: 600 601 625 718 725 Incoloy series: 800 800H 825 925 Hastelloy series: B,B2,B3,C,C-276,C-4,C-22 Pure: Ni200, Ni201 |

||

|

Specifications

|

Round bar

|

Diameter:4~300mm

|

|

|

Flat bar

|

Thickness

|

1.0~100mm

|

|

|

Width

|

1~1500mm

|

||

|

Square bar

|

Size: 4*4-100*100mm

|

||

|

Length

|

2m, 5.8m, 6m, or as required.

|

||

|

Surface

|

Black, peeled, polishing, bright, sand blast, hair line, etc.

|

||

|

Price Term

|

Ex-work, FOB, CFR, CIF, etc.

|

||

|

Delivery Time

|

Standard size is in stock,prompt delivery or as order's quantity.

|

||

|

Package

|

Export standard package, bundled or be required.

The inner size of container is below: 20ft GP: 5.9m(length) x 2.13m(width) x 2.18m(high)about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

||

Precision-Machined Monel400 Round Steel with Excellent Strength Temperature Resistance

Monel 400 round steel, a premium nickel-copper alloy product, stands out for its precision machining capabilities, exceptional mechanical strength, and reliable performance across extreme temperature ranges. These attributes make it a preferred material for industries requiring components that balance dimensional accuracy with resistance to harsh operating conditions. Below is a detailed breakdown of its chemical composition, mechanical properties, standards, equivalent grades, applications, and related Monel 400 products.

1. Chemical Composition

The superior performance of Monel 400 round steel is rooted in its carefully calibrated chemical composition, where nickel (the core corrosion-resistant element) and copper (for ductility and strength) form the alloy’s foundation. Trace elements are strictly controlled to optimize machining, strength, and stability. The typical composition adheres to global industrial standards, as shown below:

| Element | Content Range (%) |

|---|---|

| Nickel (Ni) | 63.0 – 70.0 |

| Copper (Cu) | 28.0 – 34.0 |

| Iron (Fe) | ≤ 2.5 |

| Manganese (Mn) | ≤ 2.0 |

| Carbon (C) | ≤ 0.3 |

| Silicon (Si) | ≤ 0.5 |

| Sulfur (S) | ≤ 0.024 |

2. Mechanical Properties

Monel 400 round steel delivers outstanding mechanical performance, with strength and ductility tailored to withstand both low and high temperatures (ranging from -200°C to 480°C). Its properties are particularly optimized for precision-machined components, where dimensional stability and load-bearing capacity are critical. Below are typical values (annealed condition, unless noted otherwise):

| Property | Unit | Typical Value | Relevant Standard |

|---|---|---|---|

| Tensile Strength | MPa | ≥ 550 | ASTM B164 |

| Yield Strength (0.2% offset) | MPa | ≥ 240 | ASTM B164 |

| Elongation (in 50mm) | % | ≥ 35 | ASTM B164 |

| Hardness (Brinell) | HB | ≤ 150 | ASTM E10 |

| Modulus of Elasticity | GPa | 179 | - |

| Density | g/cm³ | 8.80 | - |

Cold-Worked Variation: For applications demanding higher strength (e.g., high-pressure fittings), cold-worked Monel 400 round steel is available. This variant offers tensile strength of 700–800 MPa and yield strength of 450–550 MPa, with slightly reduced elongation (15–25%).

3. Standards for Monel 400 Round Steel

To ensure consistency, precision, and reliability, Monel 400 round steel is manufactured and inspected in compliance with globally recognized standards. These standards govern chemical composition, mechanical properties, dimensional tolerances, and quality control:

| Standard Organization | Standard Number |

|---|---|

| ASTM (USA) | ASTM B164 |

| ASME (USA) | ASME SB-164 |

| ISO (International) | ISO 6208 |

| DIN (Germany) | DIN 17750 |

| JIS (Japan) | JIS H4551 |

These standards ensure that Monel 400 round steel meets the precision needs of industries like aerospace, oil and gas, and chemical processing.

4. Equivalent Grades

Monel 400 is known by different designations across regional standard systems. This helps in global procurement and ensures compatibility with local manufacturing practices. Below are its key equivalent grades:

| Standard System | Equivalent Grade | Region/Country |

|---|---|---|

| UNS (Global) | N04400 | International (widely used for material identification). |

| ASTM/ASME | Monel 400 | USA, Canada, and global markets. |

| ISO | NiCu30Fe | Europe, Asia, and other ISO-adopting regions. |

| DIN | 2.4360 | Germany, Austria, and European Union. |

| BS (UK) | NA12 | United Kingdom and Commonwealth nations. |

| JIS (Japan) | NW4400 | Japan, South Korea, and Southeast Asia. |

5. Applications of Precision-Machined Monel 400 Round Steel

Leveraging its precision machinability, strength, and temperature resistance, Monel 400 round steel is used to manufacture critical components across diverse industries. Key applications include:

Oil & Gas Industry

- Downhole components: Precision-machined valve stems, drill collars, and wellhead fittings—resist corrosion from sour gas (H₂S) and high temperatures (up to 480°C).

- Offshore equipment: Bolts, nuts, and flange connectors for offshore platforms—withstand seawater corrosion and wave-induced stress.

Chemical & Pharmaceutical Industry

- Process equipment: Agitator shafts, reactor internals, and heat exchanger tubes—machined to tight tolerances for leak-proof operation with acids (e.g., HCl) and solvents.

- Sanitary components: Precision-machined valves and pumps for pharmaceutical manufacturing—non-toxic, easy to clean, and resistant to sterilization cycles.

Aerospace & Defense

- Engine parts: Fuel system fittings and hydraulic components—maintain strength at cryogenic temperatures (-200°C, for LNG systems) and high temperatures (e.g., engine bays).

- Marine Defense: Submarine propeller shafts and hull fasteners—resist seawater corrosion and maintain dimensional stability under pressure.

Power Generation

- Nuclear & Thermal Plants: Turbine blades and steam valve stems—withstand high temperatures and corrosive coolants (e.g., demineralized water).

6. Other Monel 400 Products

Beyond round steel, Monel 400 is available in a range of product forms to support end-to-end manufacturing needs. These products share the alloy’s core properties (corrosion resistance, strength, temperature stability) and are often used alongside round steel in integrated systems:

| Product Form | Key Characteristics & Applications |

|---|---|

| Monel 400 Sheets/Plates | Thin to thick gauges (0.5mm–100mm); used for tank linings, heat exchanger shells, and marine hull plates. |

| Monel 400 Pipes/Tubes | Seamless and welded options; ideal for chemical transport lines, seawater cooling systems, and oil pipelines. |

| Monel 400 Wire | Fine to coarse diameters; used for welding electrodes, springs, and precision electrical components. |

| Monel 400 Forgings | Custom-machined forgings (e.g., valve bodies, pump casings); offer enhanced strength for high-pressure applications. |

| Monel 400 Fasteners | Bolts, nuts, washers, and studs; precision-threaded for secure connections in corrosive or high-temperature environments. |

These products complement Monel 400 round steel, enabling the creation of fully integrated, high-performance systems across industries.

![]()

![]()

![]()

![]()

Recommended Products