-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

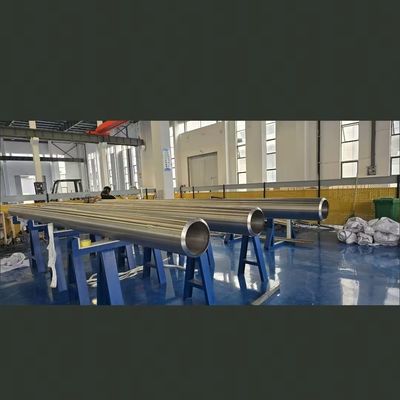

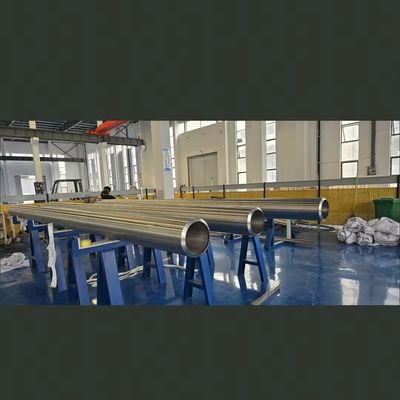

Inconel 625 Welded Pipe - Excellent Oxidation Resistance, High-Strength for Oil & Gas/Heat Exchangers, Custom Sizes Available, ISO-Certified

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Inconel 625 Pipes | Grade | Inconel 625 |

|---|---|---|---|

| Diameter | 6 - 219mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Bright |

| Highlight | Inconel 625 welded pipe with oxidation resistance,High-strength nickel alloy pipe for oil and gas,ISO-certified Inconel 625 pipe custom sizes |

||

Inconel 625 Welded Pipe - Excellent Oxidation Resistance, High-Strength for Oil & Gas/Heat Exchangers, Custom Sizes Available, ISO-Certified

More Specification Informations

| Products Name | Inconel 625 Pipes |

| Diameter | 6.0 - 219mm |

| Thickness | 0.6 - 10.0mm |

| Length | custom cutting any length as request |

| Surface | bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

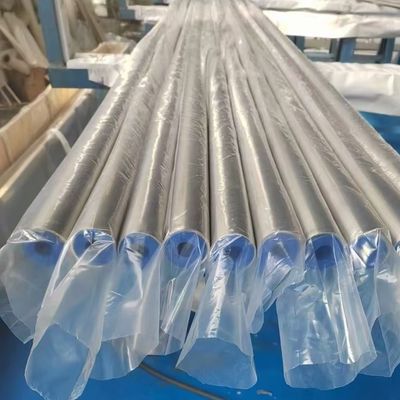

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Inconel 625 Welded Pipe - Excellent Oxidation Resistance, High-Strength for Oil & Gas/Heat Exchangers, Custom Sizes Available, ISO-Certified

Introduction: The Pinnacle of Performance in Demanding Environments

In the world of high-performance alloys, Inconel 625 stands as a benchmark for excellence, particularly in applications where extreme corrosion, heat, and pressure are the norms. Our Inconel 625 Welded Pipes embody this legacy, offering an unparalleled combination of oxidation resistance, formidable strength, and exceptional fabrication qualities. Engineered for the most critical applications in the Oil & Gas industry, heat exchangers, chemical processing, and aerospace, these pipes are not just components; they are a guarantee of reliability, safety, and longevity. As an ISO-certified manufacturer, we commit to delivering products of the highest quality, available in a wide range of custom sizes to meet your precise engineering specifications.

Unmatched Material Properties: The Science Behind Inconel 625

Inconel 625 is a nickel-chromium-molybdenum-niobium superalloy renowned for its unique chemical composition, which confers its legendary properties:

-

Excellent Oxidation Resistance: The high chromium content (approx. 20-23%) forms a robust, adherent, and passive chromium oxide layer on the surface upon exposure to heat. This layer acts as a shield, protecting the underlying material from oxidation and scaling at temperatures up to 1800°F (982°C) and beyond. This makes our welded pipes ideal for high-temperature processes.

-

Superior Corrosion Resistance: Beyond oxidation, Inconel 625 offers exceptional resistance to a wide spectrum of corrosive media. The addition of molybdenum (approx. 8-10%) provides resistance to pitting and crevice corrosion, while the nickel content ensures outstanding performance against chloride-ion stress-corrosion cracking. It withstands attacks from acids, saltwater, and alkaline solutions.

-

High Strength and Fatigue Resistance: The niobium (columbium) content acts with the molybdenum to provide dramatic strengthening of the matrix without the need for precipitation-hardening heat treatments. This grants the alloy exceptionally high tensile, creep, and rupture strength, maintaining structural integrity under intense mechanical stress and cyclic loading conditions.

Key Advantages of Our Welded Pipes

Our manufacturing process transforms this superior alloy into pipes that offer distinct benefits:

-

Consistent Quality & Dimensional Accuracy: The welded pipe process allows for excellent control over wall thickness and diameter, ensuring consistent internal and external dimensions. This is crucial for precise system design and fluid dynamics.

-

Cost-Effectiveness: For many applications, welded pipes offer a more economical solution compared to seamless pipes, especially in larger diameters and thinner walls, without compromising on the inherent properties of the Inconel 625 material.

-

Surface Finish: We provide pipes with superior internal and external surface finishes, which is critical for minimizing friction, preventing fouling, and ensuring clean operation in systems like heat exchangers.

Primary Applications: Where Performance is Non-Negotiable

-

Oil & Gas Industry: This sector demands materials that can handle extreme pressures, corrosive sour gas (H2S and CO2), and saline environments. Our Inconel 625 welded pipes are perfect for:

-

Downhole and surface equipment (e.g., tubing, casing)

-

Process piping in refineries and LNG facilities

-

Seawater cooling systems and piping

-

Acidification and fracking equipment

-

-

Heat Exchangers, Condensers, and Fired Heaters: These systems operate under high thermal cycles and corrosive conditions. The alloy's resistance to oxidation and corrosion on both the process and shell sides ensures maximum heat transfer efficiency and prevents premature failure.

-

Chemical Processing Industry (CPI): Used in reactor systems, distillation columns, and piping that handle aggressive chemicals, acids, and catalysts where contamination and failure are not an option.

-

Marine and Aerospace: Resistant to saltwater corrosion and high-temperature exhaust systems, making it a preferred choice for naval vessels and aircraft engine components.

Our Commitment to Quality: ISO Certification

Our entire manufacturing and quality assurance process is governed by strict ISO standards. This certification is your assurance that every Inconel 625 welded pipe we produce undergoes rigorous testing and inspection. This includes dimensional checks, hydrostatic testing, non-destructive testing (NDT) like eddy current or radiography to ensure weld integrity, and chemical and mechanical analysis to validate material composition and properties. Traceability is maintained from raw material to finished product.

Custom Sizes Available: Engineered to Your Needs

We understand that every project has unique requirements. Our capability to produce custom sizes is a key advantage. Whether you need specific outside diameters (OD), wall thicknesses (WT), or cut-to-length sections, we can tailor our products to fit your exact design parameters, minimizing waste and installation time.

Why Choose Our Inconel 625 Welded Pipes?

-

Proven Performance: Built from one of the most trusted alloys for extreme environments.

-

Superior Resistance: Unmatched defense against oxidation, corrosion, and high-temperature degradation.

-

High Strength: Maintains mechanical properties under stress and at elevated temperatures.

-

Reliable Supply: ISO-certified manufacturing ensures consistent, high-quality, and traceable products.

-

Customization: Flexible production to meet your exact technical specifications.

![]()

![]()

![]()

![]()