-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

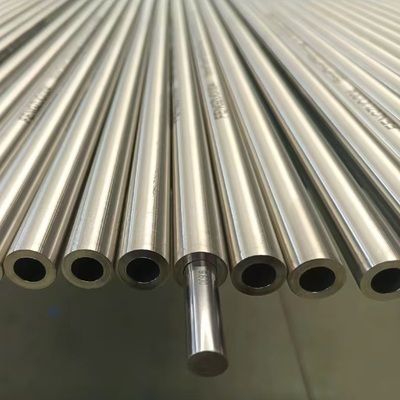

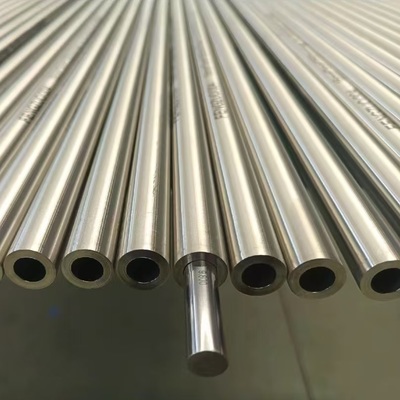

Annealed Polished Hastelloy C276 Pipe Seamless Type Precision Class 2.4819 Tube

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Hastelloy C276 Pipes | Grade | Hastelloy C276 |

|---|---|---|---|

| Diameter | 6 - 219mm | Length | Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Surface | Bright |

| Highlight | Hastelloy C276 seamless pipe,Annealed polished nickel alloy tube,Precision class 2.4819 tube |

||

Annealed Polished Hastelloy C276 Pipe Seamless Type Precision Class 2.4819 Tube

More Specification Informations

| Products Name | Hastelloy C276 pipes |

| Diameter | 6.0 - 219mm |

| Thickness | 0.6 - 10.0mm |

| Length | custom cutting any length as request |

| Surface | bright |

| Brand | DELTA |

| Service | cutting, Polishing |

| MOQ | 2 Kgs |

| Other Type | round bar, strip,coil,pipe.sheet, plate,wire.etc |

| Packing | waterproof paper and wooden pallets, wooden box |

| Loading Port | Shanghai Port |

| Price term | EXW,FOB,CIF,CFR |

| Deliver time | within 12 days |

Annealed Polished Hastelloy C276 Pipe Seamless Type Precision Class 2.4819 Tube

Product Overview

The Annealed, Polished, Seamless Hastelloy C276 (UNS N10276 / W.Nr. 2.4819) Precision Tube represents the pinnacle of corrosion-resistant alloy tubing for critical applications. This product is engineered for environments where failure is not an option, combining the superior metallurgy of the Hastelloy C276 alloy with a seamless manufacturing process, precise dimensional control, an optimal annealed heat treatment, and a polished surface finish. It is designed to handle the most aggressive chemical processes, high temperatures, and extreme pressures while maintaining integrity and longevity.

The Superiority of Hastelloy C276 (2.4819) Alloy

Hastelloy C276 is a nickel-chromium-molybdenum-tungsten alloy renowned as one of the most versatile corrosion-resistant materials available. Its key compositional elements include:

-

Nickel (Ni): Base element, providing inherent resistance to chloride-ion stress-corrosion cracking and excellent fabricability.

-

Chromium (Cr): Imparts resistance to oxidizing agents and media.

-

Molybdenum (Mo): Delivers exceptional resistance to pitting and crevice corrosion caused by reducing chemicals like chlorides.

-

Tungsten (W): Further enhances resistance to reducing environments and complements molybdenum.

A critical feature of C276 is its very low carbon and silicon content, which minimizes the precipitation of carbide phases during welding, making it exceptionally resistant to weld decay and heat-affected zone (HAZ) corrosion. This alloy withstands a vast array of severe corrosive attacks, including:

-

Pitting and Crevice Corrosion

-

Stress Corrosion Cracking (SCC)

-

Oxidizing and Reducing Environments

-

Sulfuric, Hydrochloric, and Phosphoric Acids

-

Wet Chlorine Gas and Chlorine Solutions

-

Acetic Acid and Acetic Anhydride

-

Seawater and Brine Solutions

Key Product Features and Manufacturing Excellence

-

Seamless Construction:

Unlike welded tubes, seamless tubes are extruded and drawn from a solid billet, creating a homogeneous structure with no longitudinal weld seam. This eliminates a potential weak point, ensuring uniform strength, better concentricity, and enhanced reliability under high pressure, cyclic loading, and corrosive attack. -

Precision Class Tubing:

"Precision Class" denotes tubing manufactured to exceptionally tight dimensional tolerances for outer diameter (OD), inner diameter (ID), and wall thickness. This ensures consistent performance, easy installation into manifolds, heat exchangers, and instruments, and predictable fluid flow characteristics. It is essential for applications where exact internal volumes or specific flow rates are critical. -

Annealed Heat Treatment:

The annealing process involves heating the tubing to a specific high temperature followed by controlled cooling. This crucial step:-

Relieves Stresses: Eliminates internal stresses induced during cold drawing or fabrication.

-

Optimizes Microstructure: Recrystallizes the grain structure, restoring ductility and toughness.

-

Maximizes Corrosion Resistance: Ensures the alloying elements are in solid solution, providing uniform and maximum resistance to corrosion throughout the entire tube.

An annealed tube is softer, more ductile, and easier to bend and form without cracking, making it ideal for fabricating complex systems.

-

-

Polished Surface Finish:

A mechanically polished surface finish (often specified in Ra - roughness average) offers significant benefits:-

Reduced Adhesion: A smooth surface minimizes the adhesion of process media, contaminants, and particles.

-

Easier Cleaning and Sterilization: Essential for pharmaceutical, biotech, and food processing applications where hygiene is paramount. It prevents bacterial harborage and allows for efficient Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures.

-

Enhanced Corrosion Resistance: A polished finish removes surface imperfections that can act as initiation sites for pitting and crevice corrosion.

-

Typical Applications

This high-grade tubing is specified across industries that demand absolute reliability:

-

Chemical Processing Industry (CPI): Reactor coils, heat exchanger tubes, pigtails, transfer lines for aggressive chemicals, and catalyst support grids.

-

Pharmaceutical & Biotechnology: Process piping, vent lines, pressure sense lines, and manifolds for CIP/SIP systems requiring high purity and cleanability.

-

Oil & Gas: Downhole instrumentation, umbilicals, and components handling sour gas (H2S) and chloride-containing services.

-

Pollution Control: Flue gas desulfurization (FGD) systems, scrubbers, and waste treatment systems.

-

Aerospace & Nuclear: Critical components requiring high strength and corrosion resistance in extreme environments.

-

Semiconductor Manufacturing: High-purity gas delivery systems.

Available Specifications & Standards

-

ASTM Standards: B622 (Standard Specification for Seamless Nickel and Nickel Alloy Pipe and Tube)

-

ASME Standards: SB622

-

Dimensional Standards: Can be supplied to ASTM, ASME, or specific customer dimensional requirements.

-

Size Range: Available in a wide range of outside diameters and wall thicknesses to suit various pressure ratings and application needs.

Why Choose This Product?

Selecting Annealed, Polished, Seamless Hastelloy C276 Precision Tubing is an investment in system integrity, safety, and total cost of ownership. Its unparalleled resistance to corrosion reduces downtime for maintenance and replacement, while its precision manufacturing ensures reliable and predictable performance. For engineers designing systems to handle the most challenging environments, this product offers a proven and trusted solution.

![]()

![]()

![]()

![]()