All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

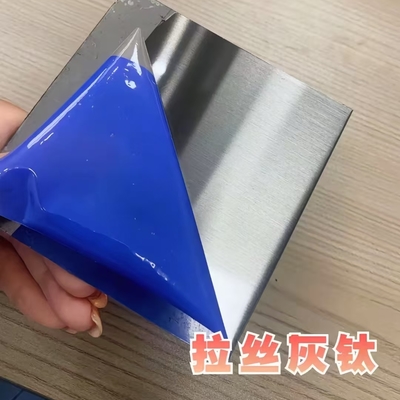

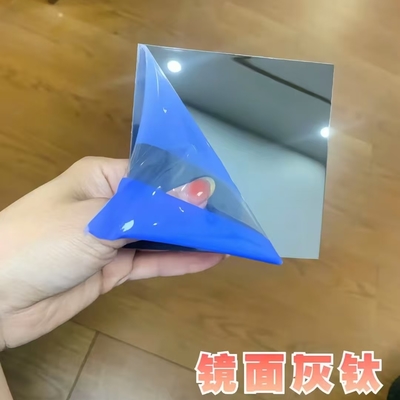

Sliver Color Stainless Steel Sheet Mirror 8K Finishing / Hairline SS Sheet NO.4 Anti-finger Print

| Place of Origin | China |

|---|---|

| Brand Name | HONGWANG |

| Certification | ISO 9001 |

| Model Number | SUS304 |

| Minimum Order Quantity | 1 Ton |

| Price | 2200 - 3200 USD/Ton |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20Ton per week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Products | Stainless Steel Sheet | Grade | SUS304 |

|---|---|---|---|

| Thickness | 0.4 - 2.0mm | Tech | Titanium |

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | Black Mirror, Gold Mirror , Hairline,etc |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | stainless steel sheet mirror finish,8K hairline stainless steel sheet,anti-fingerprint stainless steel sheet |

||

Product Description

Sliver Color Stainless Steel Sheet Mirror 8K Finishing / Hairline SS Sheet NO.4 Anti-finger Print

Products Specification

| Products Name | Colored Stainless Steel Sheet |

| Grade | SUS201 , SUS304 , SUS430 |

| Surface | 2B, BA , Mirror , NO.4 , Hairline , Gold Mirror , Gold Hairline , Bronze, Black, Blue , Gold Rose |

| Finish | Anti-Fringer Print and Laser Film |

| Width | 1000 1219mm 1500mm |

| Length | 1000-3000mm |

| Thickness | 0.40mm – 1.50mm |

1. Product Overview

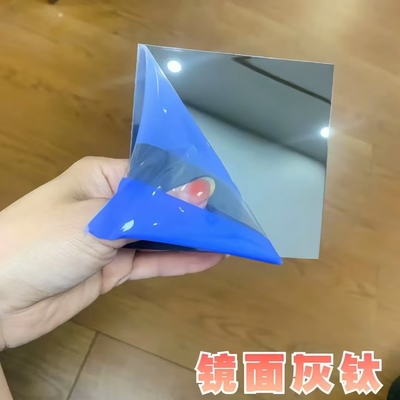

1.1 Silver Color Stainless Steel Sheet (8K Mirror Finishing)

The "8K" in the finish name refers to the reflectivity grade of the stainless steel surface, where "K" represents the degree of mirror polish (with 8K being a premium standard). Through a rigorous polishing process—typically involving multiple steps of grinding with abrasive belts (from coarse to ultra-fine, e.g., 320#, 400#, 600#, 800#, 1000#, 1200#, 1500#, and finally 2000# grit) followed by buffing with diamond paste—the surface of the stainless steel sheet achieves a mirror-like effect with near-perfect reflectivity (close to that of a glass mirror). The "silver color" denotes the natural metallic luster of stainless steel, which is bright, sleek, and resistant to yellowing or discoloration over time. This finish emphasizes elegance and modernity, making it a top choice for high-end decorative scenarios.

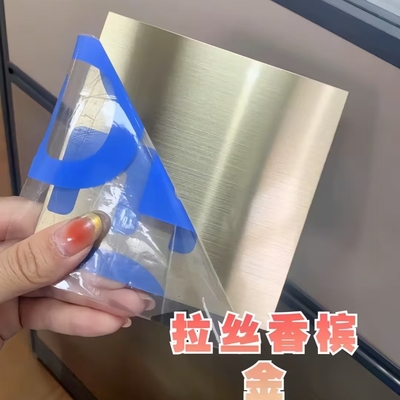

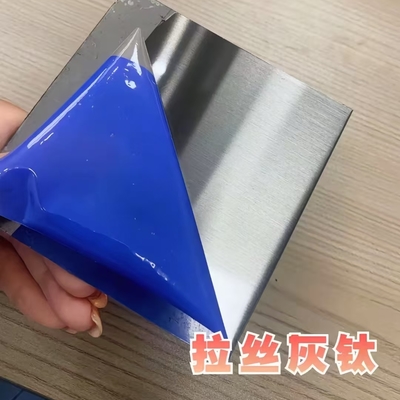

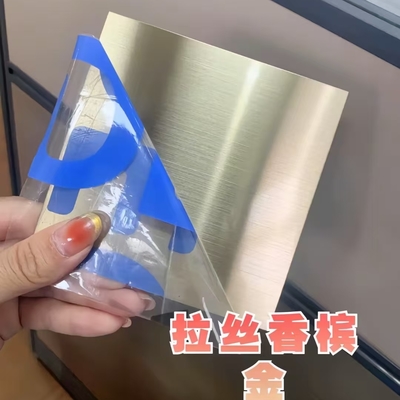

1.2 Hairline Stainless Steel Sheet (NO.4 Finish, Anti-finger Print Coating)

The "NO.4 Finish" is a widely recognized hairline finish standard defined by industrial norms (e.g., ASTM A480/A480M). It is created by mechanical brushing the stainless steel surface with abrasive belts (usually 120#–180# grit) to produce fine, parallel, and uniform linear textures (known as "hairlines"). Unlike the mirror finish, the NO.4 finish has a matte, low-gloss appearance that reduces light reflection and hides minor scratches, offering a subtle, industrial-chic aesthetic.

The "Anti-finger Print (AFP) Coating" is a key value-added feature. A thin, transparent, and wear-resistant polymer layer is applied to the hairline surface via processes like roller coating or spray coating. This coating prevents fingerprints, oil stains, and watermarks from adhering to the sheet, making daily cleaning and maintenance significantly easier—while preserving the original hairline texture and silver color.

2. Common Stainless Steel Grades

The choice of grade directly affects the sheet’s corrosion resistance, strength, and cost. Below are the most widely used grades for these two finishes:

| Finish Type | Common Grades | Key Characteristics |

|---|---|---|

| 8K Mirror Finishing | 304 | - Most popular grade (18% Cr, 8% Ni) - Excellent corrosion resistance (suitable for indoor/outdoor use) - Good formability (easy to bend, cut, or weld) - Cost-effective for general decorative needs |

| 316 | - Higher corrosion resistance than 304 (adds 2% Mo) - Ideal for harsh environments (coastal areas, kitchens with heavy oil, or chemical zones) - Higher cost, used in premium projects |

|

| 201 | - Economic grade (17% Cr, 5% Ni, 6% Mn) - Lower corrosion resistance than 304 (not recommended for outdoor or humid areas) - Suitable for budget-friendly indoor decorative applications (e.g., furniture trim) |

|

| Hairline NO.4 (AFP Coated) | 304 | - Industry standard for AFP hairline sheets - Balances corrosion resistance and affordability - Widely used in kitchen cabinets, elevator panels, and appliance surfaces |

| 316 | - Premium choice for high-humidity or corrosive environments (e.g., marine-grade furniture, laboratory countertops) - AFP coating enhances its durability further |

|

| 430 | - Ferritic stainless steel (17% Cr, no Ni) - Good corrosion resistance for dry indoor areas - Lower cost than 304, suitable for non-food-contact decorative parts (e.g., wall panels) |

3. Standard Sizes & Thicknesses

These stainless steel sheets are produced in standard dimensions to meet most application needs, with custom sizes available via cutting or slitting (minimum order quantities may apply).

3.1 Standard Sizes (Length × Width)

- Common Industrial Sizes:

- 1220mm × 2440mm (4ft × 8ft) – The most widely used size for interior design, furniture, and small-scale projects.

- 1220mm × 3050mm (4ft × 10ft) – Suitable for larger panels (e.g., elevator walls, large cabinet doors).

- 1500mm × 3000mm (5ft × 10ft) – Used for oversized applications (e.g., building facades, large decorative walls).

- Custom Sizes: Available by request (e.g., narrow strips for trim, or large coils for continuous processing in industrial production).

3.2 Thickness Ranges

Thickness is selected based on the sheet’s intended use (e.g., load-bearing requirements, flexibility needs):

| Application Scenario | Thickness Range | Typical Uses |

|---|---|---|

| Light Decorative Parts | 0.3mm – 1.0mm | Furniture trim, small appliance panels, nameplates |

| General Decorative Panels | 1.0mm – 3.0mm | Wall panels, elevator interiors, kitchen backsplashes, cabinet doors |

| Structural/Heavy-Duty Use | 3.0mm – 10.0mm | Countertops, table surfaces, outdoor decorative structures, machine casings |

4. Key Applications

The unique aesthetics and performance of these two finishes make them suitable for a wide range of industries:

4.1 8K Mirror Finish Stainless Steel Sheets

- Interior Design: Luxury hotel lobbies (column cladding, ceiling panels), high-end residential living rooms (accent walls, mirror frames), and retail store displays (showcases, brand logos).

- Architecture: Facades of modern buildings (curtain walls, decorative columns), glass curtain wall spandrels, and outdoor art installations (reflective surfaces enhance visual impact).

- Furniture & Appliances: High-end furniture (tabletops, cabinet fronts), refrigerator doors, and range hood surfaces (bright finish elevates product appearance).

- Automotive & Marine: Luxury car interior trim (dashboard panels, door handles), and yacht cabin decorations (resistant to saltwater corrosion when using 316 grade).

4.2 Hairline NO.4 (AFP Coated) Stainless Steel Sheets

- Kitchen & Bath: Cabinet doors, countertops, backsplashes, and sink surrounds (AFP coating resists oil and water stains, easy to clean).

- Elevators & Transportation: Elevator car walls, door panels, and subway station decorative panels (matte finish reduces glare, hairline texture hides scratches).

- Appliances & Electronics: Microwave ovens, washing machine exteriors, and smartphone/tablet stand surfaces (AFP coating prevents fingerprint smudges).

- Commercial Spaces: Office partition walls, restaurant tabletops, and hospital interior panels (hygienic, easy to disinfect, corrosion-resistant).

5. Packaging Solutions

To ensure the stainless steel sheets arrive in perfect condition (free from scratches, dents, or corrosion) during transportation and storage, professional packaging is essential:

5.1 Inner Packaging (Per Sheet Protection)

- Plastic Film: Each sheet is wrapped in a thick, transparent polyethylene (PE) film to prevent dust, moisture, and direct contact with other surfaces.

- Protective Paper: For 8K mirror finish sheets (highly sensitive to scratches), an additional layer of kraft paper or non-woven fabric is used between the PE film and the sheet to avoid micro-scratches.

- Edge Protectors: Plastic or cardboard edge guards are installed on all four corners of the sheet to prevent dents or bending during handling.

5.2 Outer Packaging (Bulk Protection)

- Wooden Pallets: Sheets are stacked horizontally on sturdy wooden pallets (compliant with international shipping standards, e.g., ISPM 15 for fumigation-free wood) to facilitate lifting with forklifts.

- Wooden Crates: For high-value sheets (e.g., 316 grade 8K mirror sheets) or long-distance sea shipping, sheets are packed in sealed wooden crates with foam padding inside to absorb shocks and prevent moisture intrusion.

- Strapping: The stacked sheets on pallets are secured with steel or PET straps to prevent shifting during transportation.

5.3 Special Packaging for AFP-Coated Sheets

- AFP-coated surfaces are slightly more sensitive to abrasion than uncoated sheets. Therefore, the inner plastic film is made of low-friction material, and no adhesive tapes are used directly on the AFP surface to avoid coating damage.

![]()

![]()

![]()

![]()

Recommended Products