-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

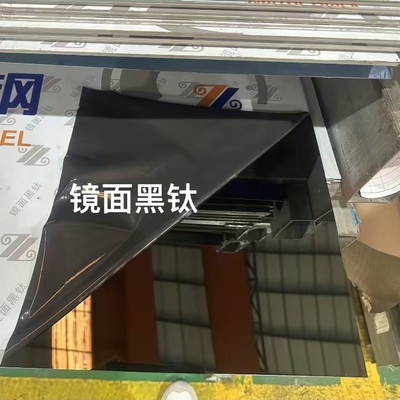

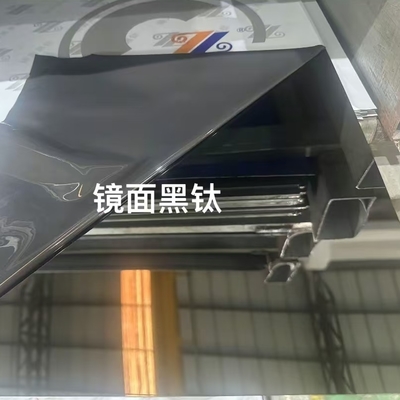

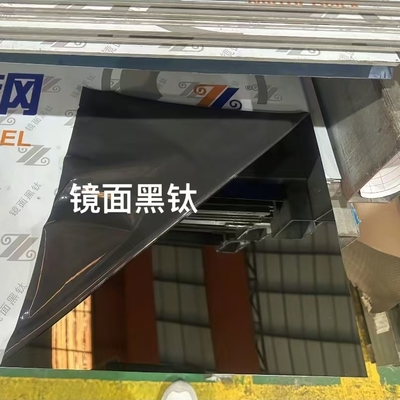

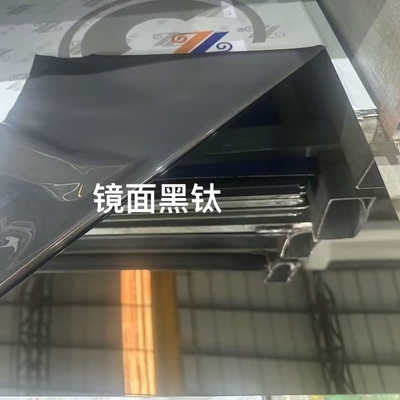

Black Mirror Stainless Steel Sheet SUS304 Matte Balck SS Sheet Thickness 0.5 - 1.5mm

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Products | Stainless Steel Sheet | Grade | SUS304 |

|---|---|---|---|

| Thickness | 0.4 - 1.5mm | Tech | Cold Rolled |

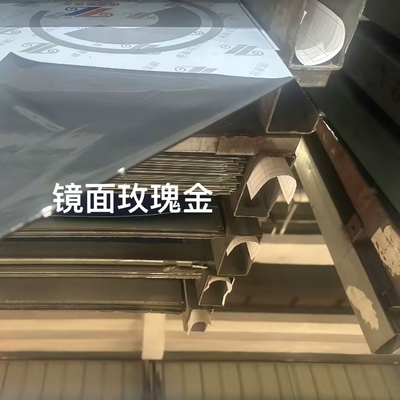

| Width | 1000mm 1219mm 1500mm Or Customs As Request | Surface | Black Mirror, Gold Mirror , Hairline,etc |

| Standard | ASTM GB JIS EN DIN | MOQ | 1 Ton |

| Highlight | black mirror stainless steel sheet,SUS304 matte black SS sheet,stainless steel sheet 0.5-1.5mm |

||

Black Mirror Stainless Steel Sheet SUS304 Matte Balck SS Sheet Thickness 0.5 - 1.5mm

Products Specification

| Products Name | Colored Stainless Steel Sheet |

| Grade | SUS201 , SUS304 , SUS430 |

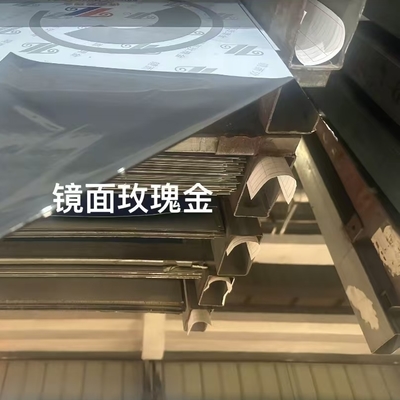

| Surface | 2B, BA , Mirror , NO.4 , Hairline , Gold Mirror , Gold Hairline , Bronze, Black, Blue , Gold Rose |

| Finish | Anti-Fringer Print and Laser Film |

| Width | 1000 1219mm 1500mm |

| Length | 1000-3000mm |

| Thickness | 0.40mm – 1.50mm |

Black Mirror Stainless Steel Sheet SUS304 Matte Black SS Sheet Thickness 0.5 - 1.5mm

Product Overview

In the realms of modern architecture, high-end appliance manufacturing, and sophisticated interior design, the quest for a material that seamlessly merges unparalleled durability with profound aesthetic appeal is never-ending. The SUS304 Matte Black Mirror Stainless Steel Sheet is the definitive answer to this quest. This product represents the pinnacle of material engineering, transforming the renowned robustness of Type 304 (SUS304) stainless steel into a stunning, contemporary masterpiece through an advanced Physical Vapor Deposition (PVD) coating process.

Unlike conventional paints or electroplated finishes, our matte black PVD coating is not merely a layer on the surface; it is a molecular-level integration that becomes a permanent part of the steel itself. This results in a surface that is not only visually striking with its deep, lustrous black mirror effect and muted matte sheen but also exceptionally resistant to fading, scratching, corrosion, and fingerprinting. It is the ideal choice for applications where both performance and visual drama are non-negotiable.

Key Features and Advantages

-

Superior Corrosion Resistance: At its core lies AISI 304 stainless steel, an alloy containing 18% chromium and 8% nickel. This composition forms a passive chromium oxide layer on the surface, providing inherent resistance to oxidation, rust, and a wide range of chemicals, making it suitable for both indoor and harsh outdoor environments.

-

Exquisite Matte Black PVD Coating: The Physical Vapor Deposition process occurs in a high-tech vacuum chamber where titanium ions are vaporized and bonded to the stainless steel substrate at an atomic level. This creates a coating that is:

-

Extremely Durable: Highly resistant to abrasion, wear, and chipping.

-

Fade-Resistant: The rich, deep black color will not fade or discolor under prolonged exposure to UV light from the sun.

-

Uniform and Consistent: The vacuum process ensures an even, consistent color and finish across the entire sheet, free from streaks or blotches.

-

Easy to Clean: The non-porous, smooth surface resists dirt, oil, and fingerprints. Most marks can be effortlessly wiped away with a soft, damp cloth and a mild detergent.

-

-

Aesthetic Versatility: The "Black Mirror" finish offers a unique combination of reflectivity and a soft, matte texture. It absorbs and reflects light in a way that is both dramatic and subtle, avoiding the glare of a pure polished mirror while creating depth and sophistication. It is the perfect material for creating a bold, modern, or minimalist statement.

-

Excellent Formability and Weldability: Despite its advanced coating, the base 304 stainless steel retains its excellent mechanical properties. It can be cut, bent, folded, and welded (with care to protect the coated surface in weld zones) to suit complex architectural and design requirements. The ductility of the 0.5mm - 1.5mm thickness range makes it versatile for various applications.

-

Hygienic and Eco-Friendly: The non-porous surface prevents the growth of bacteria, mold, and mildew, making it an excellent choice for kitchen surfaces, medical environments, and food processing areas. Furthermore, PVD is an environmentally friendly process that produces no hazardous waste compared to traditional plating techniques.

Applications

This versatile material is specified by architects and designers for a multitude of applications, including:

-

Architectural Cladding & Facades: Creating stunning, weather-resistant building exteriors.

-

Interior Wall Panels & Feature Walls: Adding a dramatic focal point in lobbies, hotels, restaurants, and luxury residences.

-

High-End Kitchen Appliances: Ovens, range hoods, refrigerators, and dishwasher panels.

-

Commercial & Residential Elevator Interiors.

-

Signage, Branding, and Decorative Trim.

-

Modern Furniture: Tables, countertops, cabinets, and shelving.

-

Automotive Trim and Accents.

Technical Specifications

The following table provides a detailed breakdown of the product's technical attributes:

| Parameter | Specification | Details / Notes |

|---|---|---|

| Base Material | AISI 304 / SUS304 / JIS SUS304 | 18/8 Stainless Steel (18% Chromium, 8% Nickel) |

| Surface Finish | Matte Black PVD Coating | Applied via Physical Vapor Deposition. A protective film is often applied to prevent scratching during fabrication and installation. |

| Available Thickness | 0.5mm (0.02"), 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm (0.06") | Custom thicknesses outside this range may be available upon request. |

| Standard Sheet Sizes | 1000mm x 2000mm (1m x 2m), 1219mm x 2438mm (4ft x 8ft), 1500mm x 3000mm (1.5m x 3m) | Other sizes can be custom-cut. |

| Tolerance | Thickness: ±0.02mm ~ ±0.05mm (depending on gauge) | |

| Hardness | Base Material HV150-200 | |

| PVD Coating Hardness | ≥ HV800 (Vickers Hardness) | Extremely scratch-resistant. |

| Corrosion Resistance | Excellent | Resists atmospheric corrosion, moisture, and many chemicals. Suitable for coastal environments. |

| Temperature Resistance | Base Material: Up to 800°C (1472°F) continuously. PVD Coating: Stable up to ~300°C (572°F) | Prolonged exposure to high heat can cause discoloration of the PVD layer. |

| Weldability | Good | Use TIG welding for best results. The heat-affected zone will lose its black color and will require post-weld touch-up with a matching PVD pen or local treatment. |

| Cleaning | Mild soap (dish detergent) and warm water. Use a soft cloth or sponge. | Avoid abrasive cleaners, scouring pads, or chlorine-based chemicals. |

Selection Guidance

-

Choosing Thickness: For purely decorative applications like interior accent walls or cabinet door overlays, 0.5mm to 0.8mm is often sufficient. For applications requiring more rigidity, such as furniture tabletops, elevator panels, or exterior cladding (on a supportive substrate), 1.0mm to 1.5mm is recommended.

-

Handling and Fabrication: Always use tools and workstations free of contaminants to prevent scratching the surface. Leave the protective film on for as long as possible during the fabrication process. When bending, ensure tools have smooth, polished surfaces to prevent marring the finish.

-

Maintenance: For daily cleaning, simply wipe with water. For tougher grime, use a dedicated stainless steel cleaner for PVD finishes. Always wipe in the direction of the grain (if visible) or the original polishing lines.

![]()

![]()

![]()

![]()