All Products

-

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

Raian IonescuMaterial quality very good. we have cooperate more than 10 Years. They trade lots kinds of steel material. All material quality good. They duty for all material quality. We are planing continue cooperate with them in the future

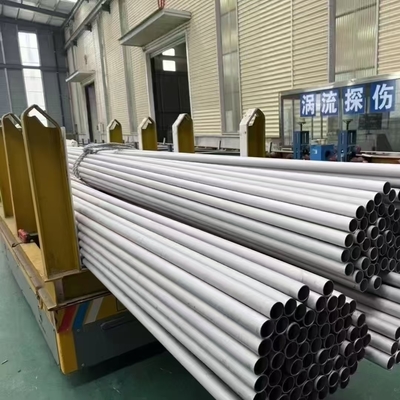

310S / 1.4845 / TP310S / 06Cr25Ni20 Stainless Steel Seamless Pipe / Welded Pipe for Boiler

| Place of Origin | China |

|---|---|

| Brand Name | DELTA |

| Certification | ISO |

| Model Number | TP310S / 1.4845 |

| Minimum Order Quantity | 1000 kgs |

| Price | 6.1 - 7.8 USD/Kg |

| Packaging Details | standard packing for export |

| Delivery Time | 5 - 12 days based on the quantity |

| Payment Terms | L/C,T/T,Western Union |

| Supply Ability | 4 Ton per week |

Product Details

| Products | Stainless Steel Seamless Pipe | Grade | TP310S / 1.4845 |

|---|---|---|---|

| Diameter | DN10 - DN400 | Length | 6m Or Custom Cutting Any Length As Request |

| Standard | ASTM EN | Service | Cutting |

| Loading Port | Shanghai Port | Thickness | 4.0 - 50.0mm |

| Highlight | 310S stainless steel boiler pipe,1.4845 seamless steel pipe,06Cr25Ni20 welded stainless pipe |

||

Product Description

310S / 1.4845 / TP310S / 06Cr25Ni20 Stainless Steel Seamless Pipe / Welded Pipe for Boiler

Products Specification

| Products Name | TP310S Stainless Steel Seamless Pipe |

Grade: |

304 304L 304LN 304H 309S 310S 314 315 316L 316Ti 317L 321 329 347H 410 2205 2507 2550 S32760 904L 254SMO and equal grade in GB JIS EN DIN Standard |

| Standards: | ASTM A213M-94b ASTM A249M-94a ASTM A269-94a ASTM A312M-94b,ect. ASTM A790 |

| DIN 17456-85 DIN 17458-85 DIN 17459-92.ect | |

| JIS G3446-1994 JIS G3448-1997 JIS G3459-1997 JIS G3463-1994,ect. | |

| GB13296-1991 GB14975-2002 GB14976-2002,ect. | |

| Size: | ND5 - DN400 |

| Length: | 6m length or cutting any length as request |

| Applications: | fluid and gas transport, structure , boiler, heat exchanger, super heater |

310S / 1.4845 / TP310S / 06Cr25Ni20 Stainless Steel Seamless Pipe / Welded Pipe for Boiler

310S stainless steel (also designated as 1.4845 under EN standards, TP310S under ASTM standards, and 06Cr25Ni20 under Chinese GB standards) is a high-temperature resistant austenitic stainless steel primarily composed of 25% chromium (Cr) and 20% nickel (Ni). Its excellent oxidation resistance, creep strength, and thermal stability make it ideal for boiler systems—where pipes are exposed to continuous high temperatures, high pressure, and corrosive flue gases. Below is a detailed breakdown of 310S stainless steel seamless pipes and welded pipes, covering standards, parameters, specifications, production processes, applications, and packaging.

1. 310S Stainless Steel Seamless Pipe

Seamless pipes are manufactured without welding seams, offering superior structural integrity, pressure resistance, and uniformity—critical for high-pressure boiler components (e.g., superheaters, reheaters) where weld defects could lead to leaks or failures.

1.1 Standards (International & National)

Seamless pipes adhere to strict industry standards to ensure consistency in material quality and performance:

| Standard System | Standard Number | Key Application Scope |

|---|---|---|

| ASTM (USA) | ASTM A312 / A312M | General seamless austenitic stainless steel pipes for high-temperature/pressure service |

| ASTM (USA) | ASTM A213 / A213M | Seamless ferritic and austenitic alloy steel pipes for boiler, superheater, and heat exchanger tubes |

| EN (EU) | EN 10216-5 | Seamless steel pipes for pressure purposes—Part 5: Austenitic stainless steel |

| GB (China) | GB/T 14976 | Seamless stainless steel pipes for fluid transport (covers 06Cr25Ni20) |

| GB (China) | GB/T 13296 | Seamless stainless steel pipes for boiler, heat exchanger, and condenser tubes |

1.2 Chemical Composition & Mechanical Properties

These parameters define the material’s high-temperature resistance and structural strength:

Chemical Composition (Weight %, Typical)

| Element | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) | Cr (Chromium) | Ni (Nickel) | N (Nitrogen) | Fe (Iron) |

|---|---|---|---|---|---|---|---|---|---|

| Content | ≤0.08 | ≤1.50 | ≤2.00 | ≤0.045 | ≤0.030 | 24.00-26.00 | 19.00-22.00 | ≤0.10 | Balanced |

Mechanical Properties (At Room Temperature)

| Property | Standard Requirement (ASTM A312) |

|---|---|

| Tensile Strength (σb) | ≥515 MPa |

| Yield Strength (σ0.2) | ≥205 MPa |

| Elongation (δ5) | ≥35% |

| Hardness (Brinell) | ≤217 HB |

High-Temperature Performance: Maintains structural stability at continuous service temperatures up to 1150°C; resists oxidation in air up to 1200°C (thanks to a dense Cr₂O₃ oxide film).

1.3 Specifications

Specifications vary by boiler design (e.g., small-diameter superheater tubes vs. large-diameter main steam pipes):

- Outer Diameter (OD): 6 mm – 630 mm (common ranges for boilers: 10 mm – 219 mm)

- Wall Thickness (WT): 0.8 mm – 50 mm (boiler-specific: 2 mm – 20 mm, to balance pressure resistance and heat transfer)

- Length:

- Random length: 3 m – 12 m

- Fixed length: Customized (e.g., 6 m, 9 m, 12 m) per customer/boiler design

- Surface Finish:

- Pickled (default): Removes oxide scale, improves corrosion resistance;

- Polished (optional): Ra ≤ 0.8 μm (for hygiene-sensitive boiler auxiliary systems).

1.4 Production Process

The seamless manufacturing process ensures no weak weld seams, critical for high-pressure boiler service:

- Raw Material Preparation: Use 310S stainless steel billets (continuous casting billets, Φ150 mm – Φ300 mm) with strict chemical composition testing.

- Heating: Heat billets to 1100°C – 1250°C in a walking-beam furnace (ensures uniform austenite structure).

- Piercing: Push heated billets through a piercing mill to form a hollow "tube blank" (mandrel piercing for uniform wall thickness).

- Hot Rolling/Expanding: Reduce the tube blank’s OD and WT via hot rolling (for small OD) or hot expanding (for large OD), shaping it to target dimensions.

- Heat Treatment: Solution annealing at 1050°C – 1150°C (eliminates internal stress, restores austenite structure, and enhances corrosion resistance), followed by rapid water quenching.

- Cold Finishing (Optional): For precision requirements (e.g., small-diameter boiler tubes), use cold drawing to refine OD/WT tolerance, then bright annealing.

- Inspection:

- Non-destructive testing (NDT): Ultrasonic testing (UT) for internal defects, eddy current testing (ECT) for surface defects;

- Dimensional inspection: Verify OD, WT, and straightness (≤1 mm/m);

- Pressure testing: Hydrostatic test (2.5 MPa – 5 MPa) to ensure leak tightness.

1.5 Boiler-Specific Applications

Seamless pipes are preferred for high-pressure, high-temperature core boiler components where structural integrity is non-negotiable:

- Superheater tubes (transport high-temperature steam, up to 540°C – 600°C);

- Reheater tubes (reheat steam for improved thermal efficiency);

- Main steam pipes (carry high-pressure steam from boiler to turbine, pressure up to 10 MPa – 30 MPa);

- Water wall tubes (circulate boiler feedwater, resist thermal cycling).

2. 310S Stainless Steel Welded Pipe

Welded pipes are manufactured by welding stainless steel strips/plates into tubular shapes. They offer cost advantages for large-diameter, low-to-medium pressure boiler applications, where weld seams are validated via strict testing.

2.1 Standards

Welded pipes follow standards tailored to welding quality and service conditions:

| Standard System | Standard Number | Key Application Scope |

|---|---|---|

| ASTM (USA) | ASTM A358 / A358M | Electric-fusion-welded austenitic stainless steel pipes for high-temperature service |

| ASTM (USA) | ASTM A480 / A480M | General requirements for flat-rolled stainless and heat-resisting steel plate, sheet, and strip (raw material for welded pipes) |

| EN (EU) | EN 10217-7 | Welded steel pipes for pressure purposes—Part 7: Austenitic stainless steel |

| GB (China) | GB/T 12771 | Welded stainless steel pipes for fluid transport (covers 06Cr25Ni20) |

| GB (China) | GB/T 21832 | Welded stainless steel pipes for boiler and heat exchanger |

2.2 Chemical Composition & Mechanical Properties

Nearly identical to seamless pipes (same base material), but with additional weld seam requirements:

- Chemical Composition: Same as 310S seamless pipe (see Section 1.2).

- Mechanical Properties:

- Tensile Strength (σb): ≥515 MPa;

- Yield Strength (σ0.2): ≥205 MPa;

- Elongation (δ5): ≥30% (slightly lower than seamless due to weld seam, but still meets boiler standards);

- Weld Seam Strength: Weld metal tensile strength ≥ 90% of base metal strength (ASTM A358 requirement).

2.3 Specifications

Welded pipes are cost-effective for larger diameters, common in boiler auxiliary systems:

- Outer Diameter (OD): 10 mm – 2000 mm (boiler applications: 25 mm – 630 mm);

- Wall Thickness (WT): 0.5 mm – 30 mm (boiler-specific: 1.5 mm – 15 mm);

- Length:

- Random length: 3 m – 12 m;

- Fixed length: Customized (up to 18 m for large-diameter pipes);

- Welding Type:

- TIG (Tungsten Inert Gas) welding: For small OD (≤50 mm), high weld quality (no spatter, smooth seam);

- MIG (Metal Inert Gas) welding: For medium/large OD (>50 mm), high production efficiency;

- Surface Finish: Pickled (default) or polished (optional), same as seamless pipes.

2.4 Production Process

Welded pipes prioritize weld seam quality to ensure reliability in boiler service:

- Raw Material Preparation: Use 310S stainless steel strips (thickness 0.5 mm – 30 mm) with chemical composition and flatness testing.

- Forming: Bend the stainless steel strip into a circular/oval shape via a roll-forming machine (ensures consistent OD and roundness).

- Welding:

- TIG/MIG welding under inert gas (argon) to prevent oxidation of the weld seam;

- For high-pressure boiler pipes: Use double-sided welding (root pass + fill pass) to eliminate internal weld defects.

- Heat Treatment: Solution annealing (1050°C – 1150°C) + quenching to soften the weld seam, eliminate residual stress, and restore corrosion resistance.

- Sizing & Straightening: Calibrate OD/WT via a sizing mill; straighten pipes to meet straightness requirements (≤1.5 mm/m).

- Inspection:

- Weld Seam Testing: Radiographic testing (RT) or ultrasonic testing (UT) to detect internal weld defects;

- Leak Testing: Hydrostatic test (1.5 – 3 MPa) or pneumatic test;

- Surface Inspection: Visual inspection (no cracks, pits) or eddy current testing (ECT).

2.5 Boiler-Specific Applications

Welded pipes are used in low-to-medium pressure boiler systems where cost efficiency and large diameters are prioritized:

- Boiler flue gas ducts (resist corrosive flue gases at 300°C – 800°C);

- Feedwater pipes (transport low-pressure boiler feedwater, ≤2 MPa);

- Condensate return pipes (carry condensed steam, low temperature/pressure);

- Auxiliary heat exchanger tubes (e.g., deaerator heat exchangers, ≤400°C).

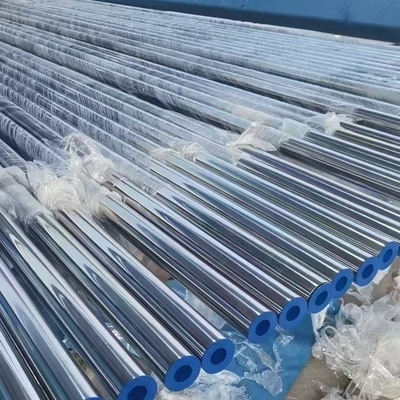

3. Packaging (Common for Both Seamless & Welded Pipes)

Packaging protects pipes from damage, corrosion, and contamination during transportation and storage—critical for boiler components (any surface scratch could lead to corrosion under high temperature):

-

Inner Packaging:

- Each pipe is wrapped in PE film (polyethylene) to prevent moisture and dust;

- Small-diameter pipes (≤50 mm) are bundled with steel straps (5 – 10 pieces per bundle);

- Large-diameter pipes (>50 mm) are individually wrapped or capped (both ends) with plastic caps to prevent debris entry.

-

Outer Packaging:

- Wooden crates: For small batches, precision pipes, or sea transport (prevents impact damage);

- Steel racks: For large batches, long-length pipes (≥6 m) – ensures stability during loading/unloading;

- Anti-rust treatment: Optional for long-term storage (apply anti-rust oil + VCI film to resist atmospheric corrosion).

-

Marking:

- Each bundle/crate is labeled with: Material grade (310S/1.4845/TP310S/06Cr25Ni20), pipe type (seamless/welded), OD/WT/length, standard number, heat number, and manufacturer’s logo.

![]()

![]()

![]()

![]()

Recommended Products